Oil inlet retractable universal connecting pipe of supercharger and method for manufacturing oil inlet retractable universal connecting pipe

A universal connection and manufacturing method technology, applied in the direction of adjustable connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as inability to assemble, too long pipes, leakage or breakage of the pipe body, and achieve improved resistance. Mechanical vibration, the effect of solving the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

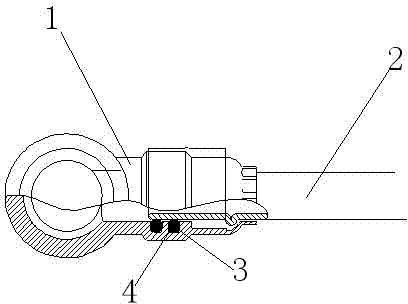

[0025] Such as figure 1 As shown, a supercharger oil inlet telescopic universal connecting pipe of the present invention includes a joint and a pipe body, the joint and the pipe body are movably connected, and the joint can be stretched or rotated relative to the pipe body. Two grooves are arranged at the junction of the pipe body, and a Viton sealing ring is arranged in each of the two grooves. The telescopic variable of the joint relative to the pipe body is 6mm, and the joint can freely rotate 360° relative to the pipe body. The width of the groove is 1.8mm, the section diameter of the Viton sealing ring is 2mm, and the inner diameter is 8mm.

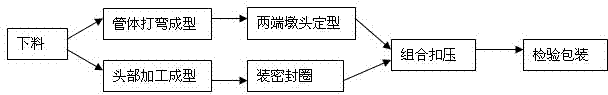

[0026] Production technology of the present invention is as follows:

[0027] 1. Blanking: According to the requirements of the engineering pipe body manufacturing process, the pipe material is cut and blanked at a fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Section diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com