Condensate water automatic discharging device for preventing air leakage of positive pressure area of air processing device

An air treatment and automatic discharge technology, applied in the direction of preventing condensed water, etc., can solve problems such as air leakage, condensed water backflow, energy waste, etc., and achieve the effect of reliable sealing and preventing air from leaking outward

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below with reference to the drawings and embodiments.

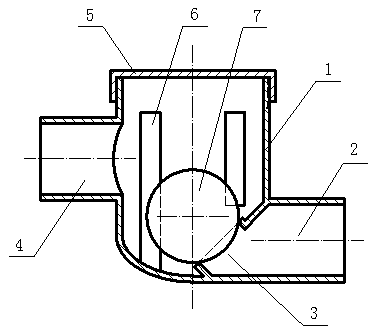

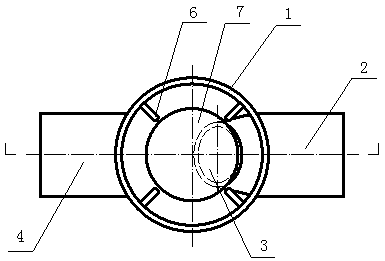

[0011] Such as figure 1 , 2 As shown, the automatic condensate discharge device for preventing air leakage in the positive pressure zone of air treatment equipment of the present invention includes a housing 1, a condensate outlet pipe 2, a drain port 3, a condensate inlet pipe 4, an upper cover 5, and a rib 6, Seal the ball 7.

[0012] The condensate water inlet pipe 4 is connected to the housing 1 at a position close to the upper part, and the condensate water outlet pipe 2 is connected to the housing 1 at a position close to the bottom. The condensate water outlet pipe 2 extends into the housing 1 with an opening on its inner end surface. The lateral drainage port 3 is provided with a sealing ball 7 above the drainage port 3 side, and the sealing ball 7 is connected to the drainage port 3 in a sealed fit.

[0013] The inner wall of the housing 1 has a plurality of ribs 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com