Heat exchanger

A heat exchanger and fin technology, applied in the field of heat exchangers, can solve problems such as easy to cause danger, easy accumulation of dust, affect heat exchange effect, etc., to ensure hygiene and safety, avoid accidents, and reduce the effect of dust accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

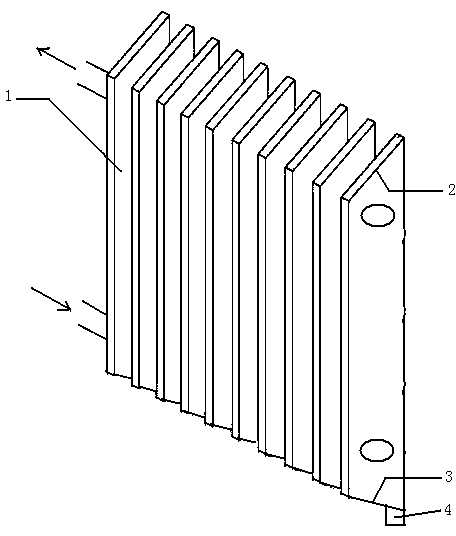

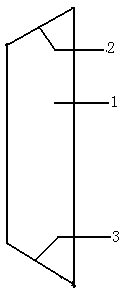

[0011] Such as figure 1 The heat exchanger includes 10 vertically arranged fins 1, the upper end surface 2 of the fin 1 is in the shape of an upright right triangle, which can reduce dust accumulation, and the lower bottom surface 3 is in the shape of an inverted right triangle , can make the condensed water droplets flow along the part of the hypotenuse of the triangle to the bottom side in time, and the lower bottom surface 3 is provided with a water receiving tank 4 below the right-angled side of the inverted right-angled triangle shape, but the condensed water drips into the water receiving tank, effectively Prevent the condensed water from condensing at the bottom of the fins, which will not easily drip and affect the heat exchange effect. The condensed water will drip into the water receiving tank, which can ensure the sanitation and safety of the working environment and effectively avoid accidents.

[0012] The present invention has been described in detail above, but t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com