Device for measuring center distance and gear backlash of gear pair

A technology of backlash and gear pair, which is applied in the measurement field of gear pair, can solve the problems of low measurement accuracy and low efficiency, and achieve the effect of improving measurement accuracy and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

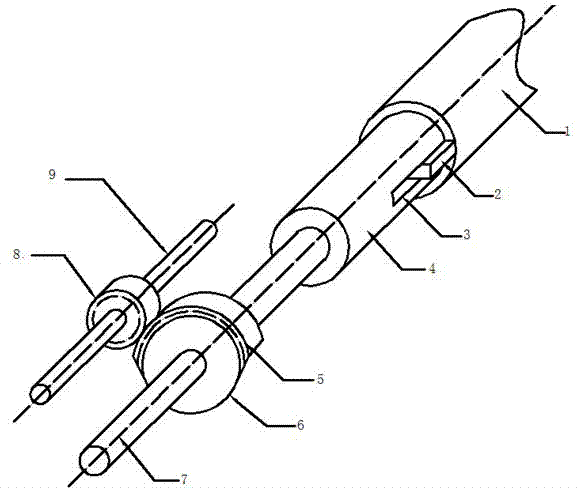

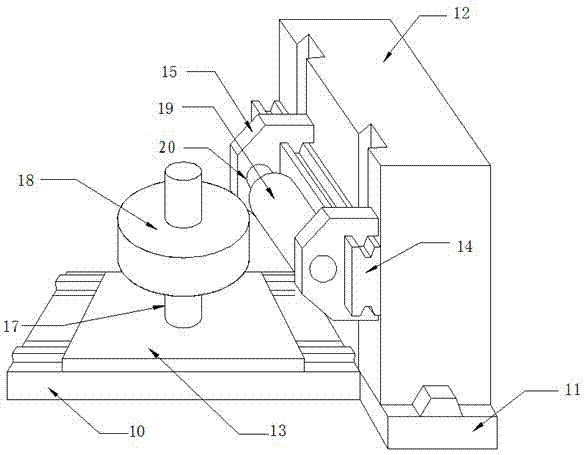

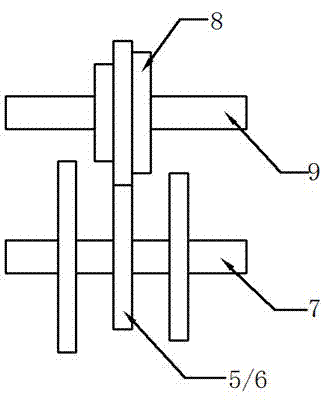

[0025] see figure 1 with figure 2 , the embodiment provides a device for measuring the center distance and backlash of the worm gear pair, including sensor measuring equipment, data processing and display equipment, installation equipment for the driven worm gear pair to be tested, and transmission equipment.

[0026] The installation equipment of the driven worm gear pair to be tested comprises base frame 10 and 11, support frame 12, sliding pallet 13 and 14, sliding support 15; Shaped mandrel 17 rotates together, and brake equipment is installed on the conical mandrel 17, and conical mandrel 17 is installed on the sliding supporting plate 13, and sliding supporting plate 13 can slide on base frame 10, is used for installing, adjusting The driven gear 18 to be measured; the sliding supporting plate 14 can slide up and down along the vertical direction on the support frame 12 to adjust the height of the driving gear 19 to be measured; the left and right sliding brackets 15 a...

Embodiment 2

[0035] see Figure 4 with Figure 5 , This embodiment provides a device for measuring the center distance and backlash of spur gear pairs, helical gear pairs, and bevel gear pairs, including sensor measurement equipment, data processing and display equipment, gear pair installation equipment and transmission equipment.

[0036] Described gear pair installation equipment to be tested comprises base frame 10 and 11, support frame 12, sliding pallet 13; Braking equipment is installed on the tapered mandrel 17, and the tapered mandrel 17 is installed on the sliding pallet 13, and the sliding pallet 13 can slide on the base frame 10, and is used for installing and adjusting the driven gear 18 to be tested; The driving gear 19 to be tested is installed on the conical mandrel 16, which can rotate together with the conical mandrel 16. The conical mandrel 16 is installed on the bracket 12; the single-tooth incomplete gear 22 is fixed on the shaft 21, and the shaft 21 Link to each oth...

Embodiment 3

[0041] When the angle α between the driving shaft 1 and the driven shaft 9 in the transmission equipment satisfies 0<α<90°, some special meshing gears can be measured by refitting the gear pair installation equipment to be tested. The measurement principle is the same as The foregoing embodiments are the same, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com