An encoder integrating motor rotor position detection and valve position stroke detection

A motor rotor and stroke detection technology, which is applied in the field of encoders, can solve the problems of increasing the failure rate of detection devices, occupying the space of valve electric actuators, reducing detection accuracy and reliability, and achieving high-precision motor position detection and position detection. Effects of improved resolution and reduced misreading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

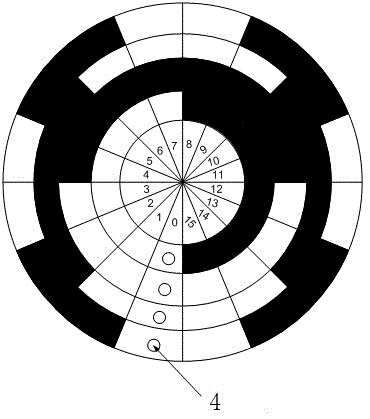

[0016] The motor rotor position detection and valve position stroke detection integrated encoder of this embodiment is to realize the rotor position detection of the switched reluctance motor with 12 / 8 structure and the valve position detection of the valve driven by the switched reluctance motor.

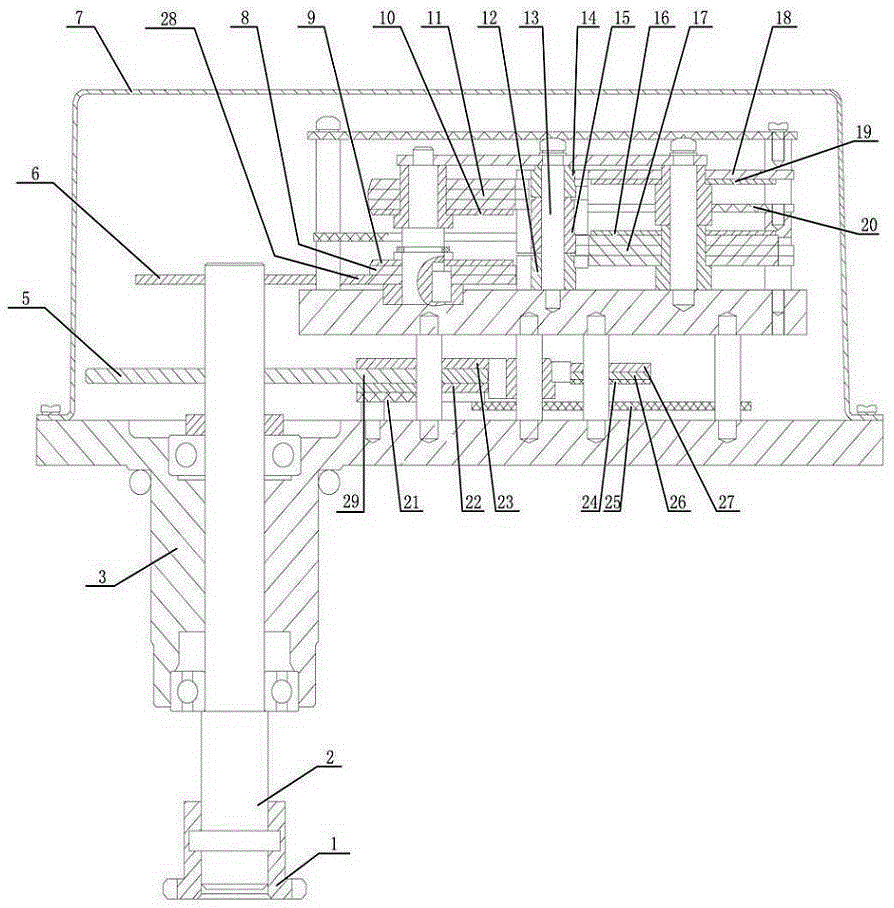

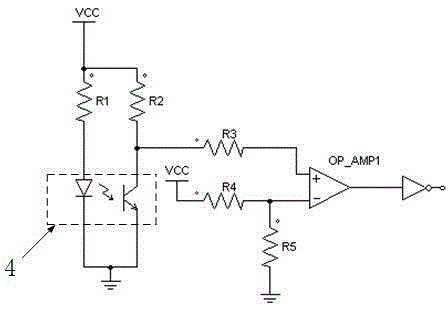

[0017] Such as figure 1 As shown, the integrated encoder for motor rotor position detection and valve position stroke detection includes stroke input shaft 2, stroke input gear 1, base 3, control circuit composed of photoelectric sensor code fetching circuit and level conversion circuit, speed-up gear 5 With reduction gear 6, speed-up gear 5 meshes with motor rotor position first floor counting gear 29, and the first code disc 22 and the first code fetching circuit of 1~4 are fixed below the rotor position first floor counting gear 29 21. The gear meshed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com