Preparation method of alumyte base beta-sialon

A technology of bauxite and high-alumina bauxite, which is applied in the field of preparation of high-alumina bauxite for reduction and nitriding to synthesize β-Sialon, can solve the problems of complicated process, high process cost, and many impurities in the synthetic product, and achieve reduction of manufacturing cost, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

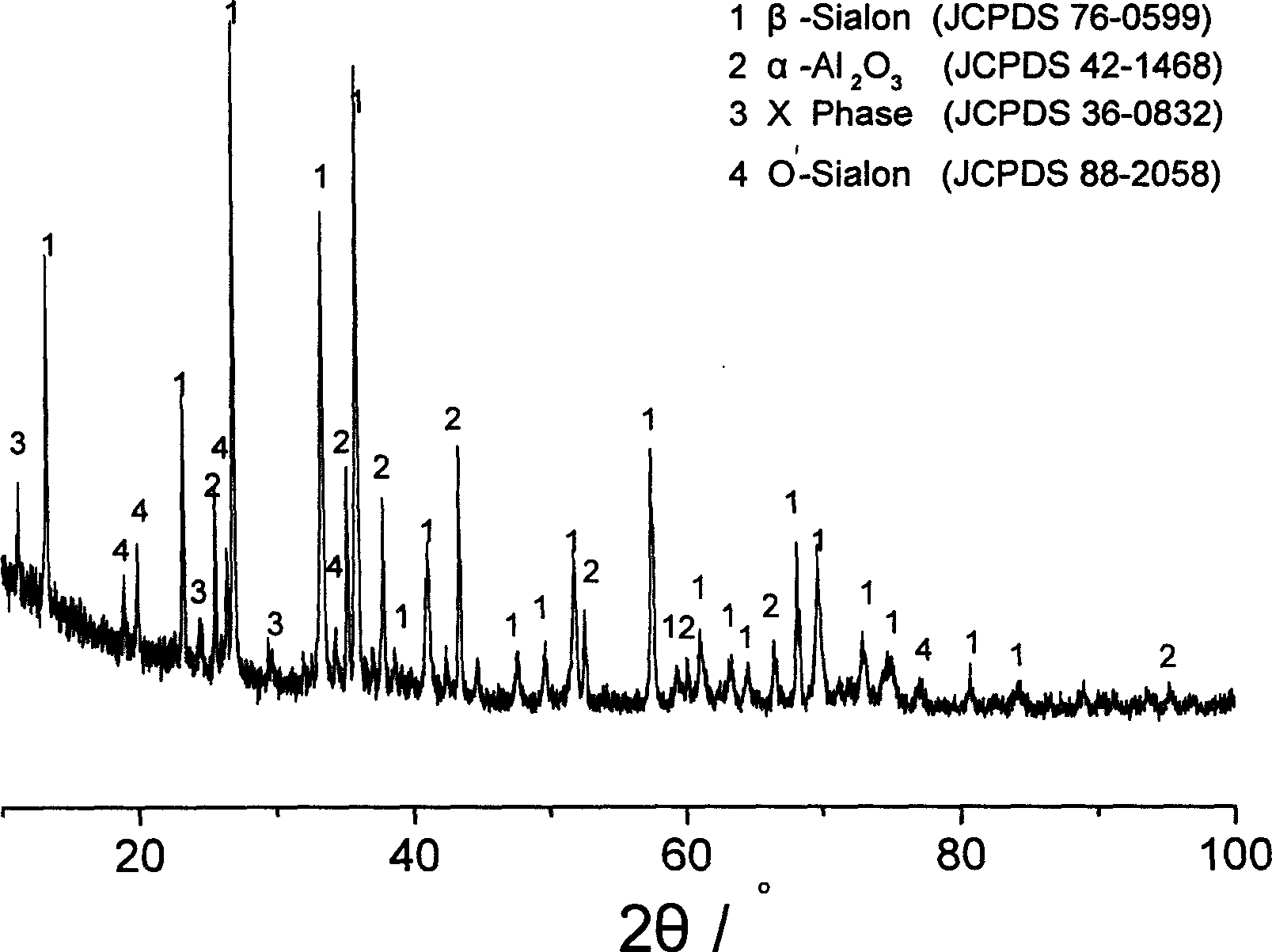

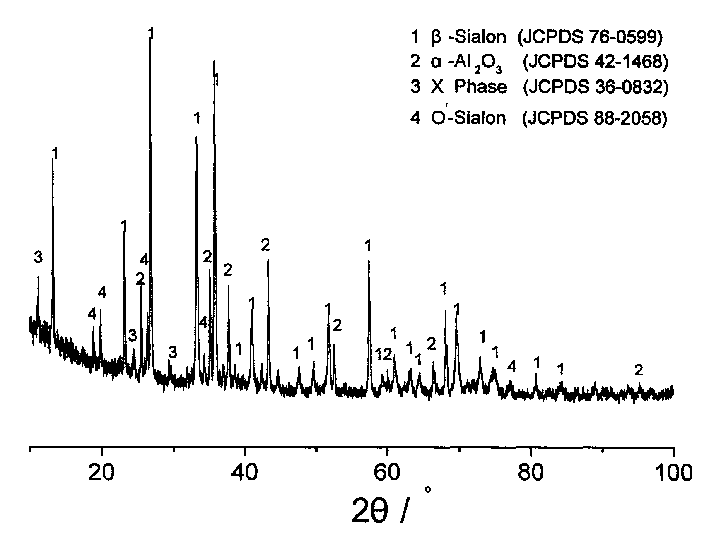

Image

Examples

Embodiment

[0028] Use high alumina bauxite (composition as shown in Table 1), metal silicon powder, and aluminum powder as raw materials, and add a small amount of β-Sialon as crystal seed.

[0029] Component

Al 2 o 3

SiO 2

Fe 2 o 3

TiO 2

CaO

MgO

K 2 o

Na 2 o

burning

wt%

79.03

1.50

0.26

3.74

0.12

0.20

0.01

0.03

14.70

[0030] Place 48 parts of bauxite, 43 parts of metal silicon powder, and 9 parts of metal aluminum powder in a ball mill tank, and dry mix them evenly; take out the mixed powder, use dextrin as a binder, and press it at 70-100MPa, 80-110 Dry at ℃ temperature.

[0031] Using an atmosphere sintering furnace, under a nitrogen atmosphere, the temperature was raised to 1500° C. in stages and kept for 5 hours. Cool down to 700°C and turn off the nitrogen gas, continue to cool down to room temperature and take out to obtain β-Sialon powder.

[0032] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com