Low cost and high performance porous beta-SiAlON ceramics, and preparation method thereof

A high-performance, low-cost technology, applied in the field of porous ceramics and materials, can solve the problems of high reaction temperature, easy carbon residue, long reaction cycle, etc., and achieve the effect of reducing manufacturing cost, simple preparation process and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The process steps are as follows:

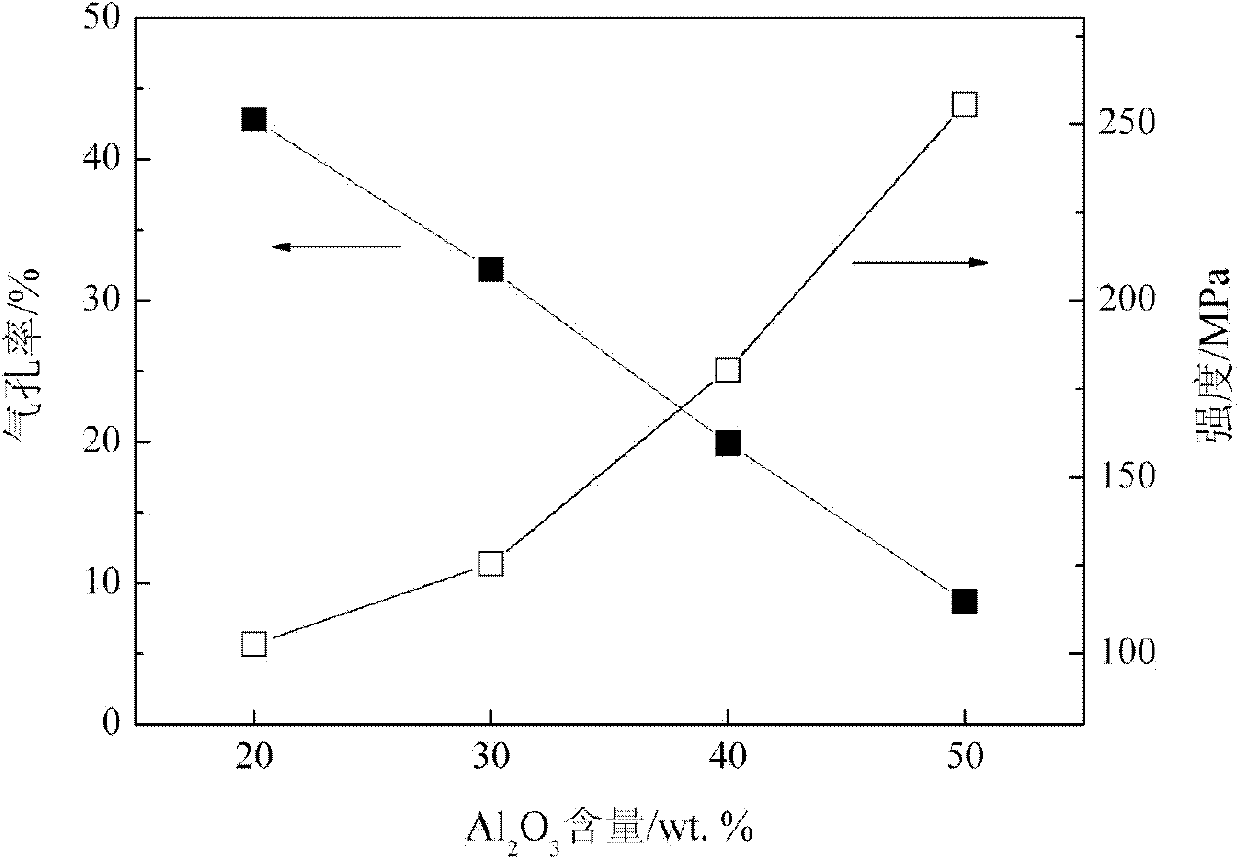

[0032] (1) Ball milling: take 30wt.% Al according to the design composition 2 o 3 After Si powder and 70wt.% Si powder, with absolute ethanol as the mixing medium, add by 60% of the total mass of the powder, use agate balls as grinding balls, powder: agate balls=1: 1 (mass ratio) , placed in a nylon tank and mixed with a rolling ball mill for 12 hours;

[0033] (2) Drying: place the wet-milled slurry in a drying oven to dry at 60°C;

[0034] (3) Molding: add 5wt.% of 10wt.% polyvinyl alcohol solution as a binder, and mold it at a uniaxial pressure of 50MPa;

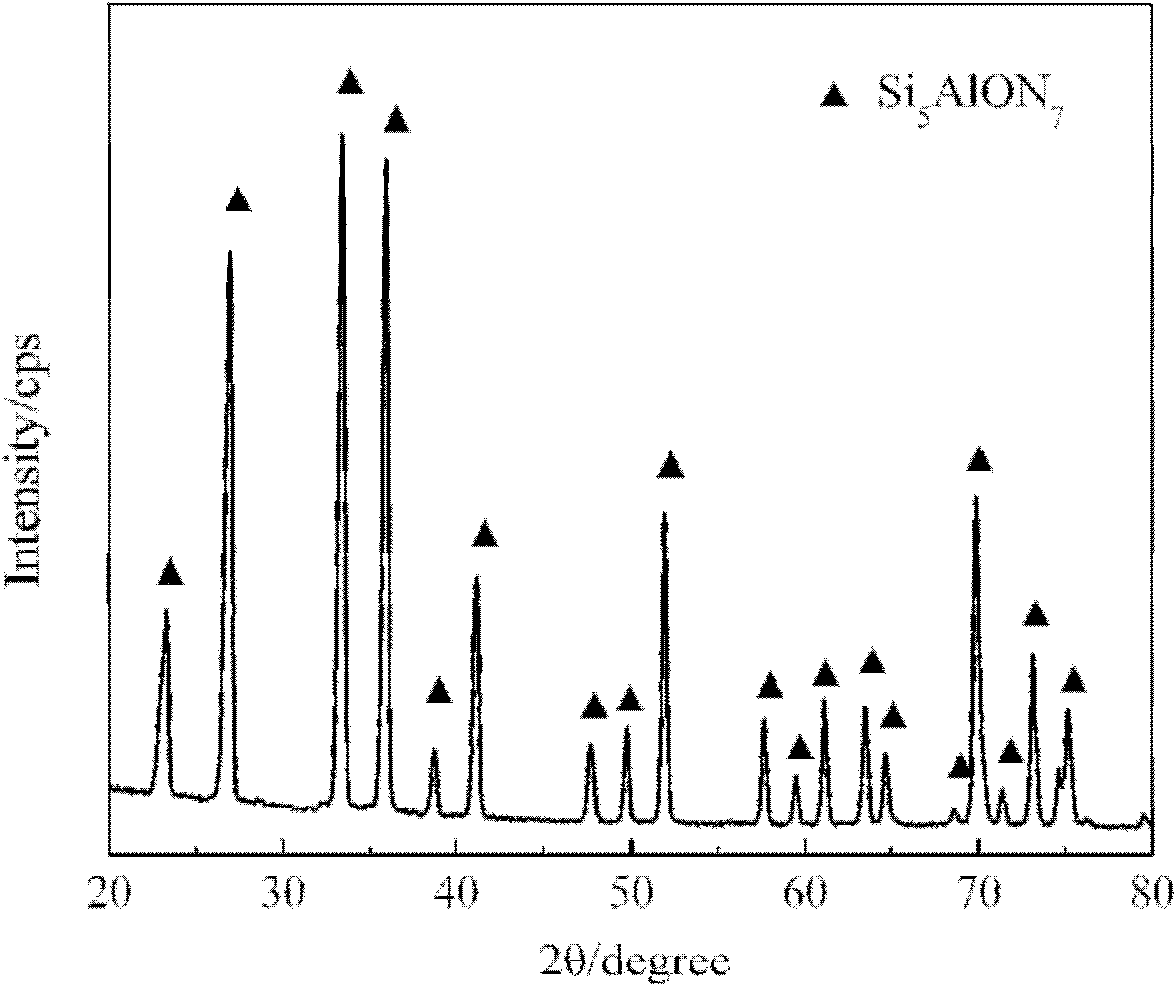

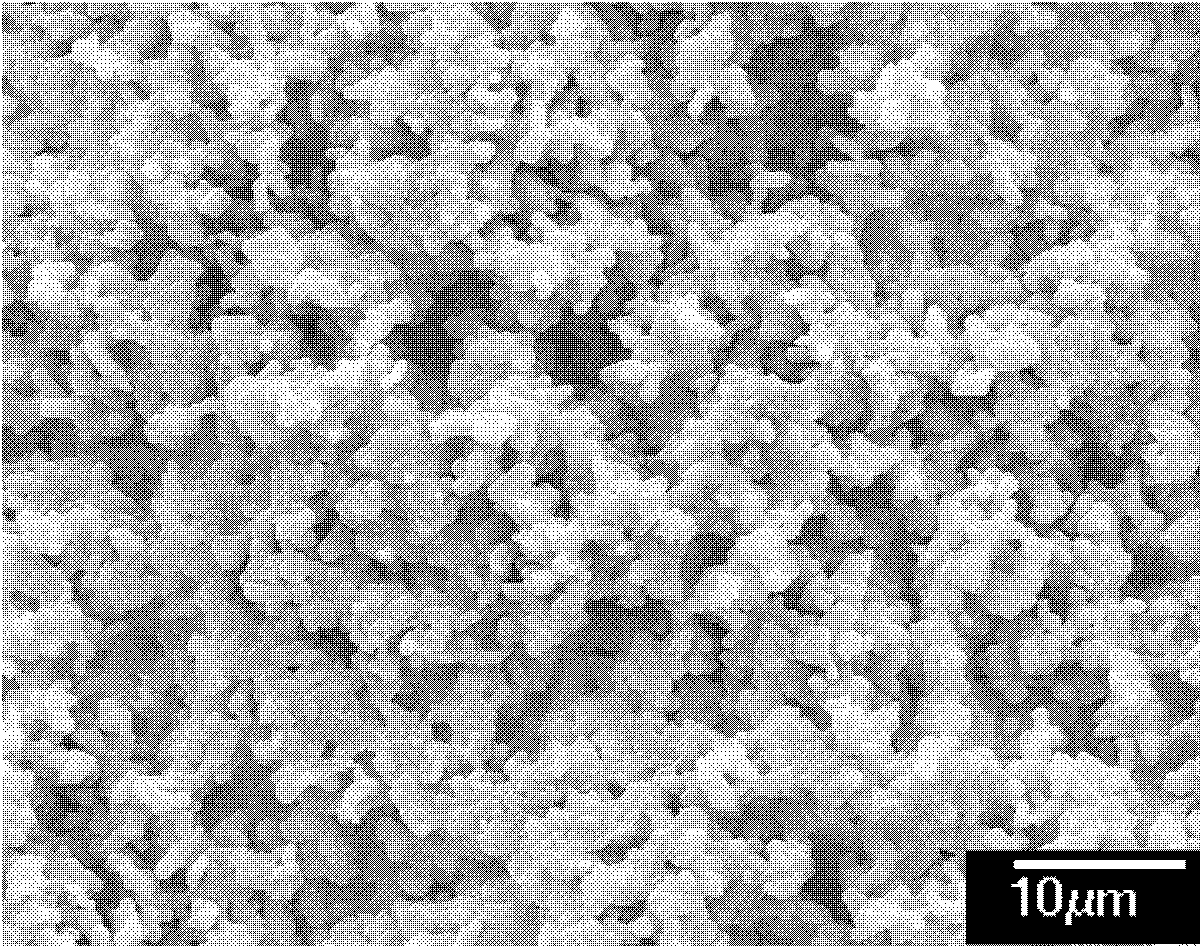

[0035] (4) Reaction sintering: reaction sintering in a nitrogen atmosphere, the sintering temperature is 1350°C, the holding time is 3h, and the nitrogen pressure is 0.6MPa;

[0036] (5) High temperature sintering: after nitriding, the sample is sintered at high temperature, the sintering temperature is 1700°C, and the holding time is 2h;

[0037] The product of the present ...

Embodiment 2

[0039] (1) Ball milling: Weigh Al according to the design composition 2 o 3 After powder is 50wt.% and Si powder is 50wt.% raw material, with dehydrated alcohol as mixing medium, add by 40% of material powder gross mass, use agate ball as grinding ball, material powder: agate ball=1: 1 (mass ratio), placed in a nylon tank and mixed with a rolling ball mill for 24 hours;

[0040] (2) Drying: place the wet-milled slurry in a drying oven to dry at 60°C;

[0041] (3) Molding: add 5wt.% of 10wt.% polyvinyl alcohol solution as a binder, and mold it under a uniaxial pressure of 200MPa;

[0042] (4) Reaction sintering: reaction sintering in a nitrogen atmosphere, the sintering temperature is 1350°C, the holding time is 3h, and the nitrogen pressure is 0.6MPa;

[0043] (5) High temperature sintering: after nitriding, the sample is sintered at high temperature, the sintering temperature is 1700°C, and the holding time is 2h;

[0044] The product of the present invention is a porous ...

Embodiment 3

[0046] (1) Ball milling: take 30wt.% Al according to the design composition 2 o 3 powder, 70wt.% Si powder and Al 2 o 3 Powder and Si powder total weight 3wt.%Y 2 o 3 Finally, with absolute ethanol as the mixing medium, add by 60% of the total mass of the material powder, use agate balls as grinding balls, material powder: agate balls=1: 1 (mass ratio), place in a nylon tank and use a roller Type ball mill mixing 24h;

[0047] (2) Drying: place the wet-milled slurry in a drying oven to dry at 60°C;

[0048] (3) Molding: Add 5wt.% polyvinyl alcohol solution with a concentration of 10wt.% as a binder, and mold it under a uniaxial pressure of 200MPa;

[0049] (4) Reaction sintering: reaction sintering in a nitrogen atmosphere, the sintering temperature is 1350°C, the holding time is 2h, and the nitrogen pressure is 0.6MPa;

[0050] (5) High temperature sintering: after nitriding, the sample is sintered at high temperature, the sintering temperature is 1700°C, and the holdi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com