Product quality monitoring method based on autoregression total projection to latent structures (T-PLS)

A product quality and autoregressive technology, applied in measuring devices, special data processing applications, instruments, etc., can solve problems such as long delays and quality variables of continuous chemical processes that cannot be measured online

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

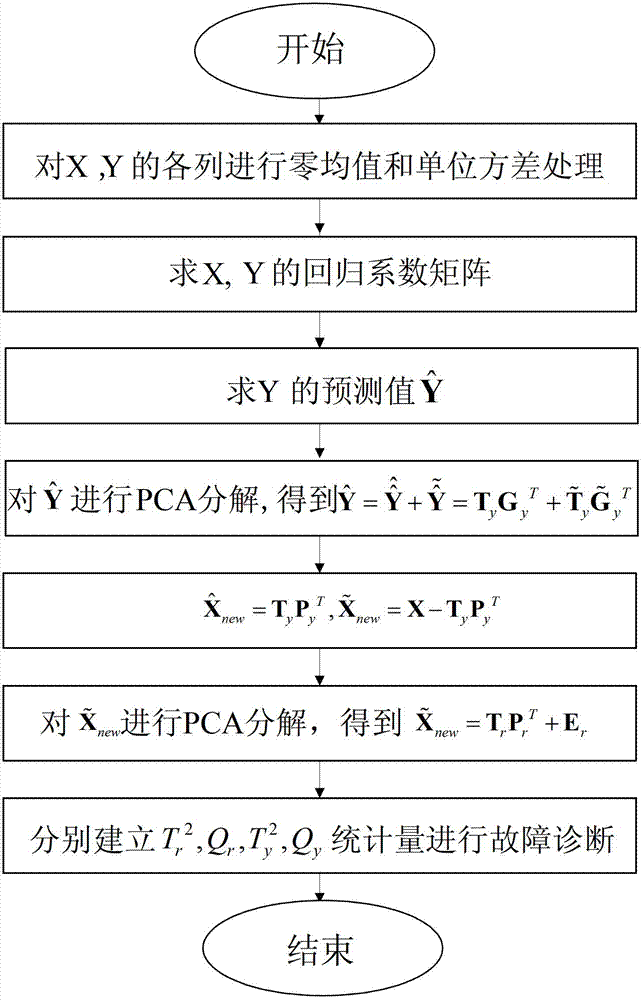

[0041] The implementation flow chart of the present invention is as figure 1 As shown, the specific implementation is as follows:

[0042] Let the input matrix , consisting of N samples, each containing n process variables; the output matrix It is also composed of N samples, and each sample is composed of m quality variables. Since changes in quality variables are usually caused by process variables, there is a certain correlation between X and Y, and X and Y can be described as follows

[0043] (1)

[0044] in Regression coefficient matrix representing information about X and Y, represents the change in mass variable that can be explained by X, Represents the part that cannot be explained by X, and satisfies

[0045] (2)

[0046]here and are X and row vector of .

[0047] because

[0048] (3)

[0049] Therefore, one can directly find

[0050] (4)

[0051] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com