Bilayer gate dielectric with low equivalent oxide thickness for graphene devices

A graphene layer, double-layer gate technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, nanotechnology for materials and surface science, etc., can solve problems such as expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

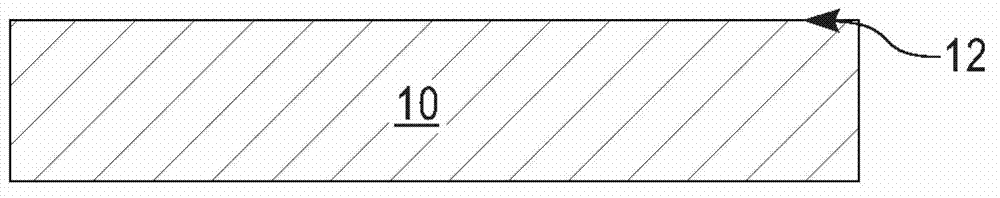

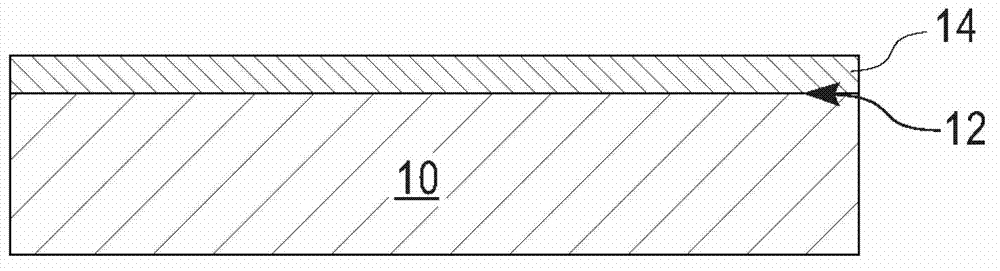

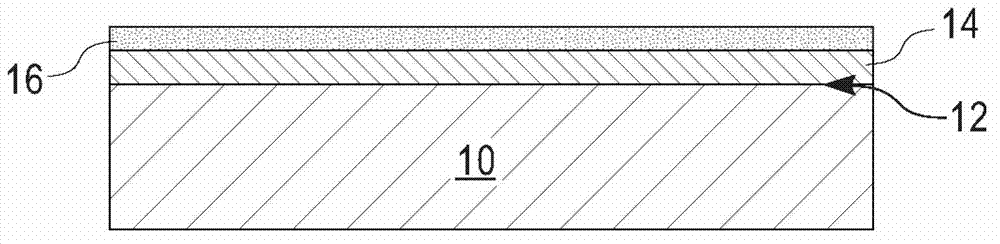

example 1

[0064] This example provides a graphene-containing structure comprising an underlying graphene layer with overlying HfO 2 between SiN layers. The structure is prepared by first providing a SiC base substrate and then epitaxially growing a graphene layer on the uppermost surface of the base substrate. The graphene layer is formed using the annealing treatment mentioned in the above detailed description of the present disclosure. After disposing a graphene layer on top of the SiC base substrate, a 2 nm thick stretched SiN layer was formed by PECVD at 400°C. Next, a 10 nm thick HfO was formed by ALD on top of the SiN layer 2 layer.

[0065] Figure 9A is an actual AFM height image of the structure after forming a SiN layer on top of the graphene layer according to this example of the present disclosure. The Z scale in nm is shown on the right. The different terrain heights of this image are indicated by the different shading corresponding directly to the shaded z-scale bar ...

example 2

[0070] This example provides a graphene-containing structure where HfO 2 layer is formed directly on the uppermost surface of the graphene layer. The structure is prepared by first providing a SiC base substrate and then epitaxially growing a graphene layer on the uppermost surface of the base substrate. The graphene layer is formed using the annealing treatment mentioned in the above detailed description of the present disclosure. After disposing a graphene layer on top of the SiC base substrate, a 10-nm-thick HfO layer was formed directly on the uppermost surface of the graphene layer by ALD. 2 layer.

[0071] Figure 13 is the direct formation of HfO on top of the graphene layer according to the present example of the disclosure 2 Actual AFM height image of the structure after the layer. The Z scale is shown on the right. Figure 14 is an example of HfO formed directly on top of a graphene layer 2 Cross-sectional AFM image of layer roughness.

[0072] SEM and AFM pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com