Remote fluorescent powder and preparation method thereof

A technology of remote phosphors and phosphors, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of destroying the crystal structure of phosphors, low LED lighting brightness, surface defects of crystal particles, etc., achieving high lighting brightness and simple materials. , the effect of small light decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

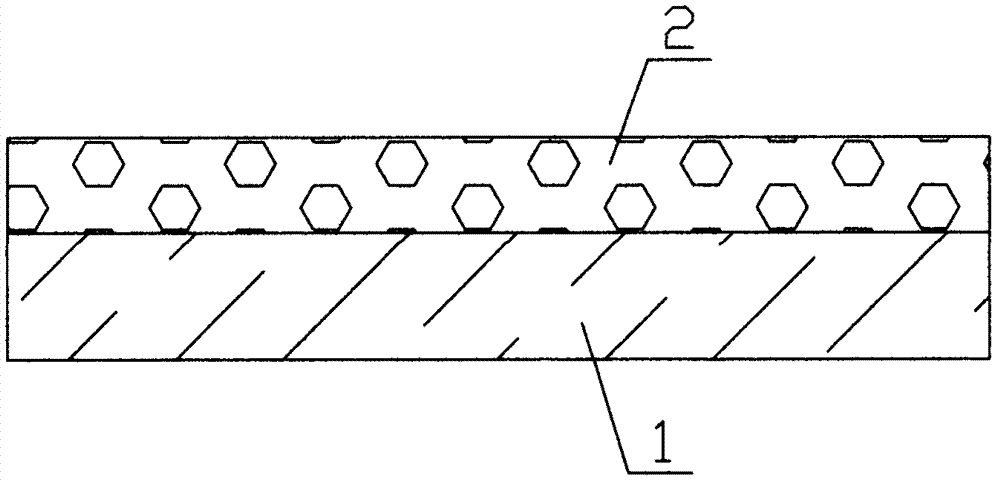

[0020] Examples, see figure 1 Shown: remote phosphor, including transparent resin layer 1 and phosphor layer 2. Wherein, the phosphor layer 2 is disposed on one side surface of the transparent resin layer 1 . The phosphor layer 2 can adopt various common phosphor layers. Optimally, the phosphor layer 2 is a mixture of phosphor, binder and coupling agent. Of course, the adhesive can be a common water-resistant or water-soluble adhesive, and the coupling agent can be a common material such as a silane coupling agent. Further, the weight ratio of the phosphor powder, binder and coupling agent in the phosphor powder layer 2 is 100:(0.01-1):(0.01-1). Optimally, the weight ratio of phosphor powder, binder and coupling agent in the phosphor powder layer 2 is 100:0.05:0.05.

[0021] The preparation method adopted fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com