An intelligent cabinet type reactive power compensation device

A compensation device and intelligent technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as different device layout, poor cabinet sealing, and falling off of the sprayed plastic layer of outgoing lines, so as to improve the protection Grade, high design reliability, good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

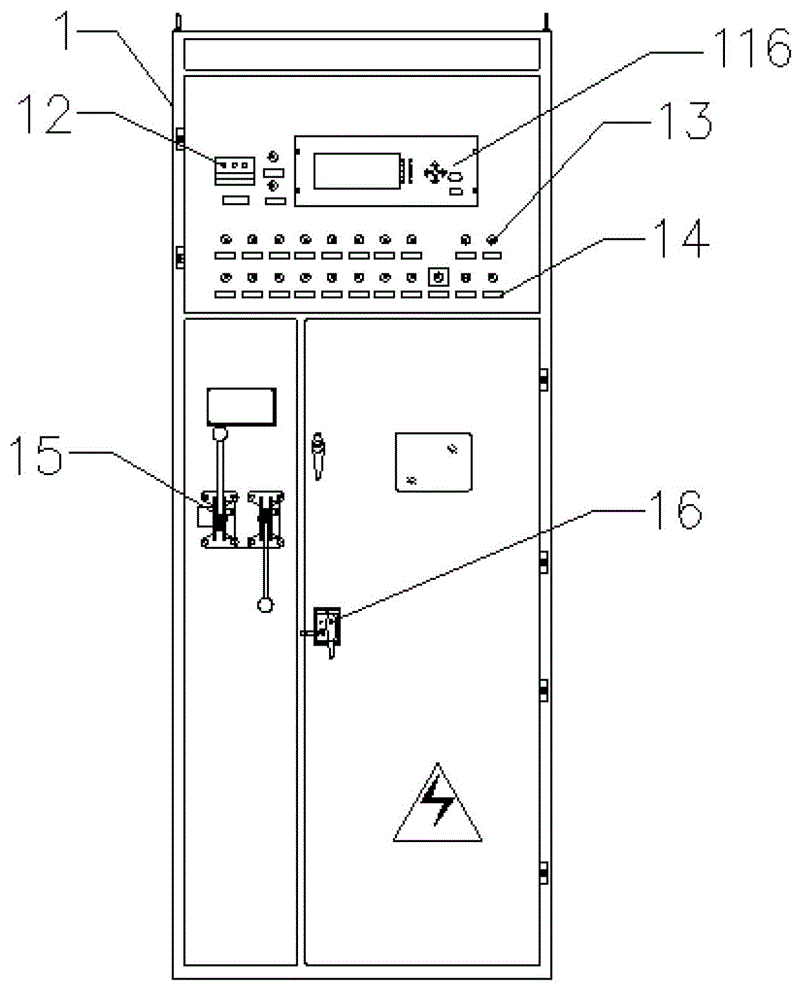

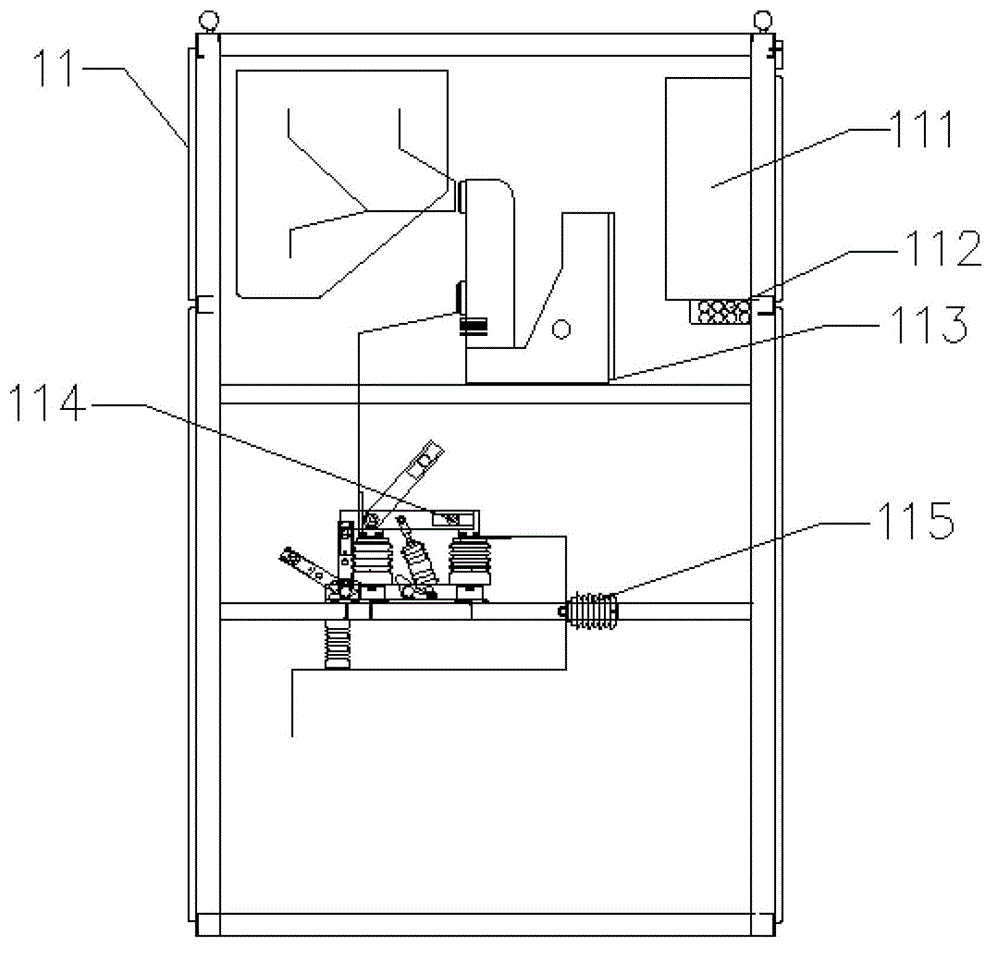

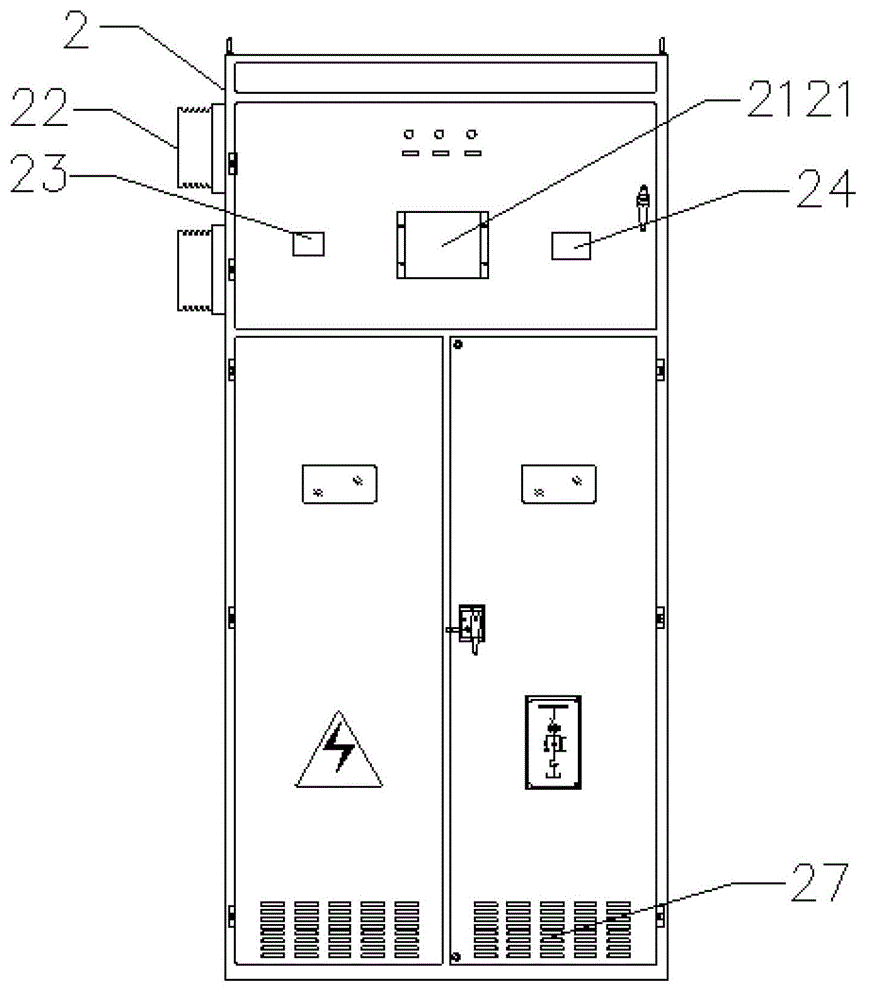

[0021] The invention discloses an intelligent cabinet-type reactive power compensation device, which includes a control cabinet 1 and a compensation cabinet 2, and the control cabinet 1 and the compensation cabinet 2 are connected through a main busbar. Such as figure 1 As shown, the control cabinet 1 includes a control cabinet body 11, an instrument panel, a display instrument 12, an indicator light 13, an operation button 14, an isolating switch operating handle 15, and an electromagnetic lock 16. The structure of the control cabinet body 11 is a fully enclosed structure. The length×width×height of the cabinet body 11 is 1000mm×1600mm×2500mm, and the outer shell of the control cabinet body 11 is made of aluminum-zinc-coated sheet and processed by electrostatic spraying. The front of the control cabinet body 11 is equipped with an instrument panel, and the instrument panel is equipped with a display instrument 12, an indicator light 13 and an operation button 14. The operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com