Design Method of Driving Moment of Large Overload Spacecraft Driving Mechanism

A technology of driving mechanism and design method, which is applied in the field of manned spaceflight engineering, and can solve the problem of not considering the elastic vibration of the flexible load battery wing and the dynamic coupling characteristics of the on-orbit overload, the inaccurate consideration of the additional resistance torque, and the stalling of the drive system To achieve the effect of shortening the working cycle, improving the prediction accuracy, improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

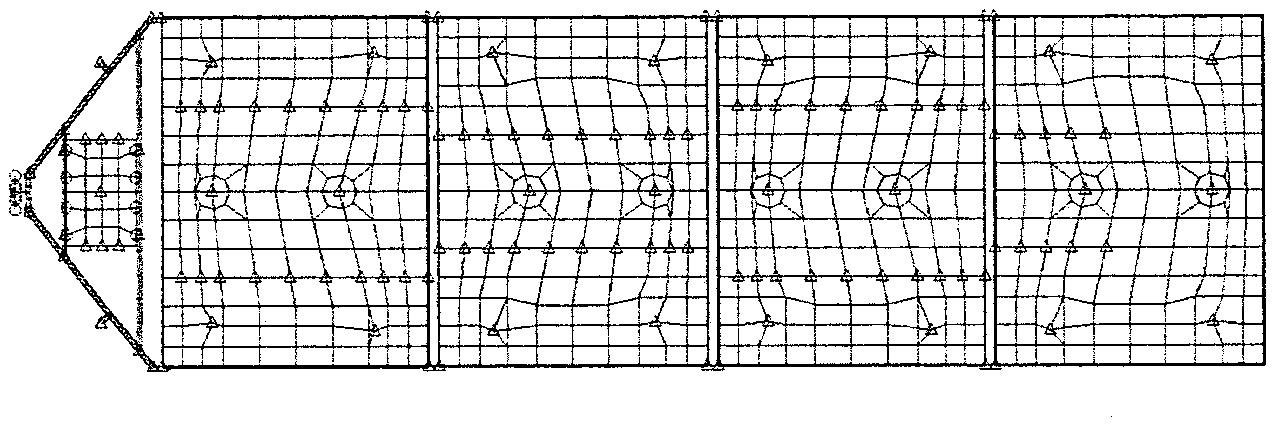

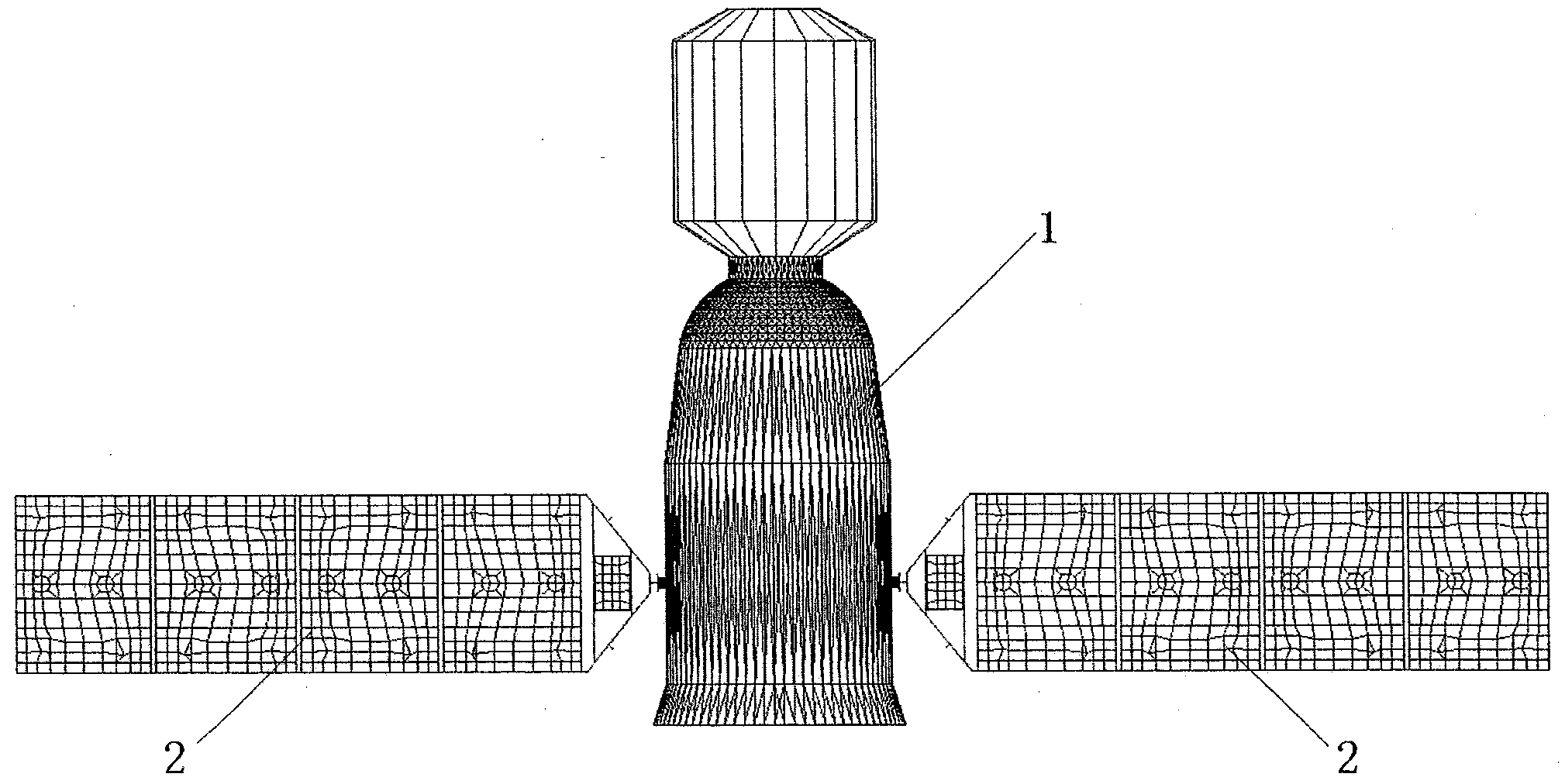

[0024] The following will combine Figure 1 ~ Figure 2 The method for designing the driving torque of the large overload spacecraft driving mechanism of the present invention is further described in detail.

[0025] The driving mechanism includes conductive slip rings, motors, reducers, zero position sensors, drive shafts, docking flanges and other components. The motor and reducer are the torque output units of the driving mechanism, and their performance is related to whether the driving mechanism can work normally. The motor and The selection of the reducer model becomes one of the key technologies in the construction of the drive mechanism. The present invention adopts reverse thinking to select the model of the motor and the reducer, that is, first accurately designs the driving torque of the spacecraft drive mechanism, and then selects the motor and reducer that meet the design index according to the design.

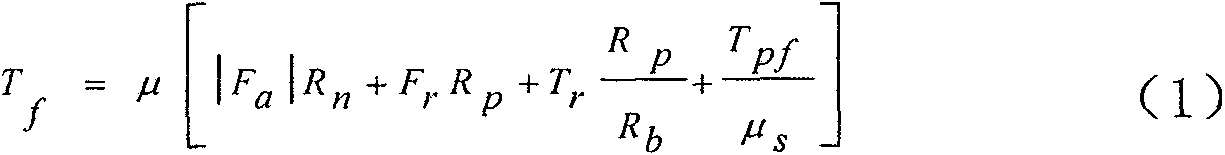

[0026] The driving torque design method of the large overloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com