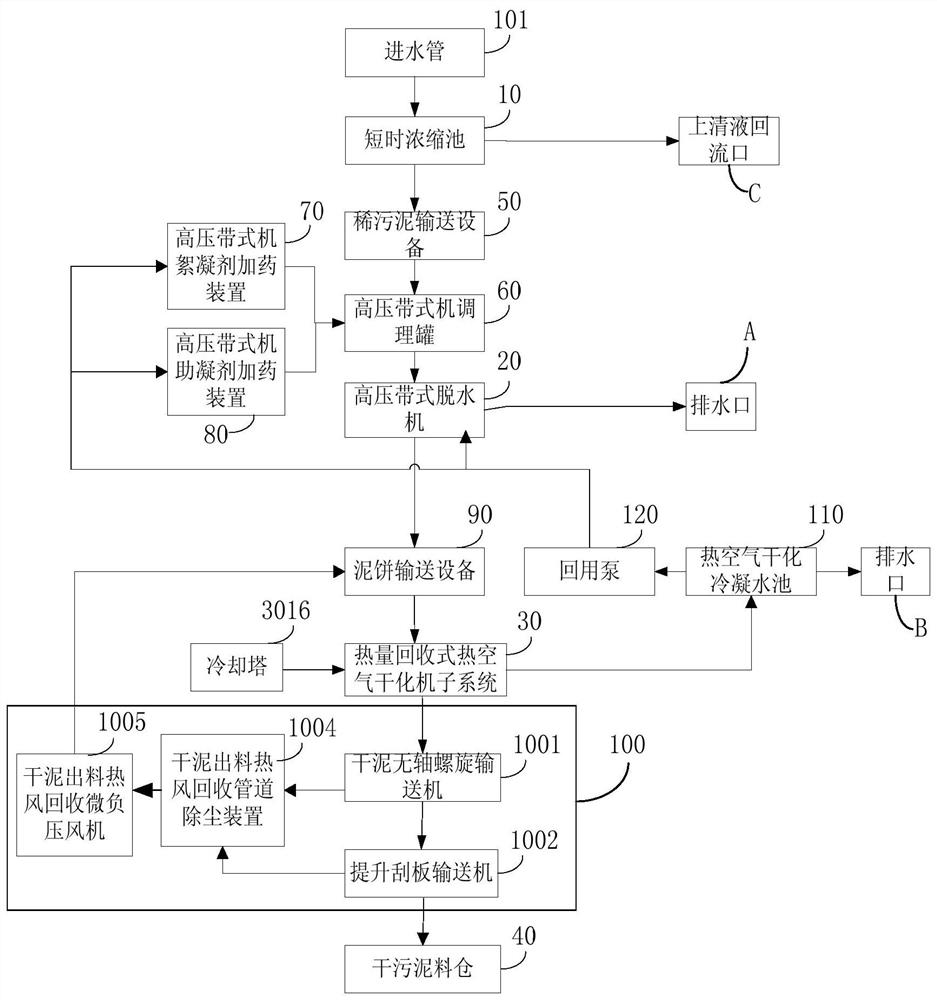

Three-stage sludge dewatering and drying system and method in domestic sewage treatment plant

A technology for domestic sewage and treatment plants, which is applied in the fields of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., and can solve the problems of difficult direct connection of domestic sewage treatment plants and no energy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

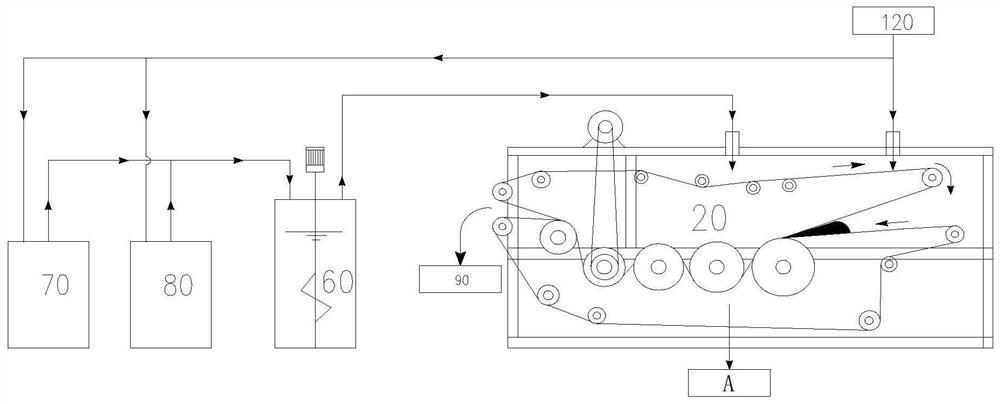

[0116] see Image 6 , this embodiment is a three-stage dehydration and drying sludge method using the above-mentioned three-stage sludge dehydration and drying system in a domestic sewage treatment plant, including:

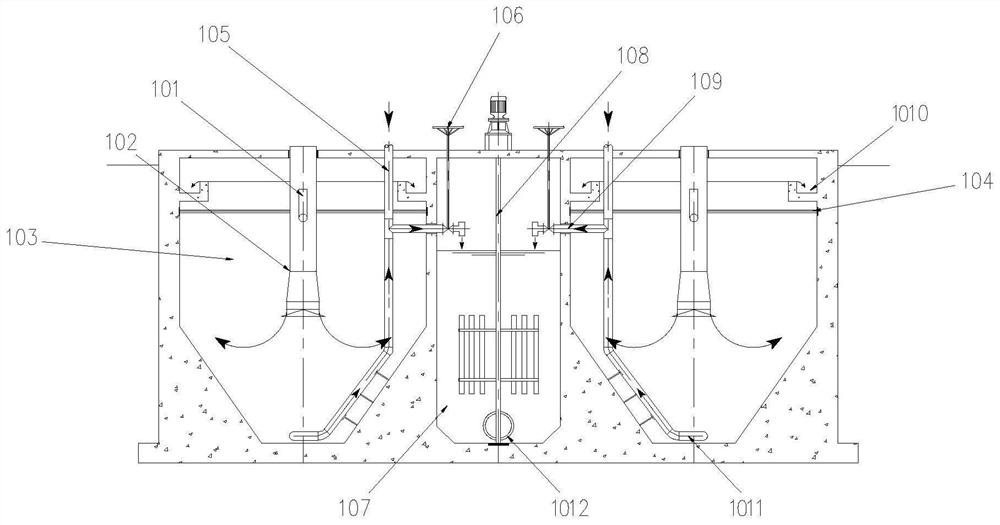

[0117] 1) In a domestic sewage treatment plant, the remaining sludge with a water content of 99.2% is pumped into the short-time concentration tank, and the sludge enters from the central cylinder of the short-time concentration tank, and the remaining sludge is guided downward through the central cylinder with a reflector Under the action of gravity, the sludge is deposited on the bottom and side wall of the short-term thickening tank. Under the action of the liquid level difference, the concentrated sludge at the bottom of the tank passes through the suction pipe at the bottom of the sludge pipe, the branch pipe of the sludge pipe, and the sludge pipe. The valve is sent to the body of the concentrated sludge storage tank by pressure, and the tank body is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com