Intelligent decision-making and design system and method for grinding disc of disc mill for pulping and papermaking

A technology for pulping and papermaking and intelligent decision-making, applied in pulp beating/refining methods, papermaking, textiles and papermaking, etc., can solve the problems of weakening the competitiveness of enterprises, wasting resources, and high production costs, so as to shorten the research and development cycle and scientifically design The effect of modernization and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] Be 15 ° SR with beating degree, fiber average length is 2.9mm, width is 22.79um, fine fiber content 6.35% kraft bleached jute pulp prepares tea bubble bag paper as an example to illustrate the implementation steps of the present invention.

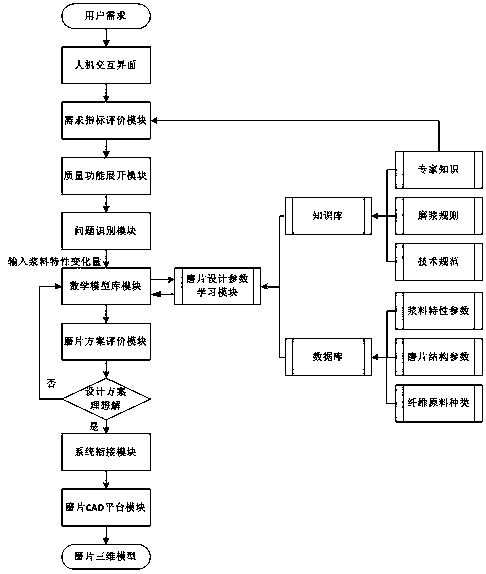

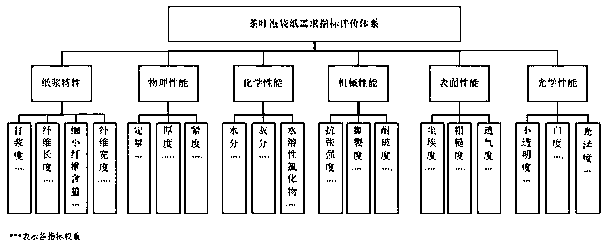

[0050] Step 1. The intelligent decision-making system receives the fiber raw material characteristics of the user before refining: beating degree 15°SR, fiber average length 2.9mm, width 22.79um, fine fiber content 6.35% kraft bleached jute pulp, to prepare tea After the information and requirements of the bubble bag paper, the user requirements are sorted into demand indicators of a hierarchical structure, compared with the models already stored in the demand indicator evaluation module, and the weight of each demand indicator is obtained, that is, the importance of the demand elements is as follows image 3 shown;

[0051] Step 2. Bring the importance of user demand elements into the quality house of the quality function expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com