Acoustic generator with elastic position correction function

A generator and functional technology, applied in the field of sound waves, can solve problems such as the inability to generate actual electric energy that can be output and applied, the inability to collect and make full use of sound energy, and the inability to convert sound energy and electric energy. High electrical conversion efficiency and reduced sound energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

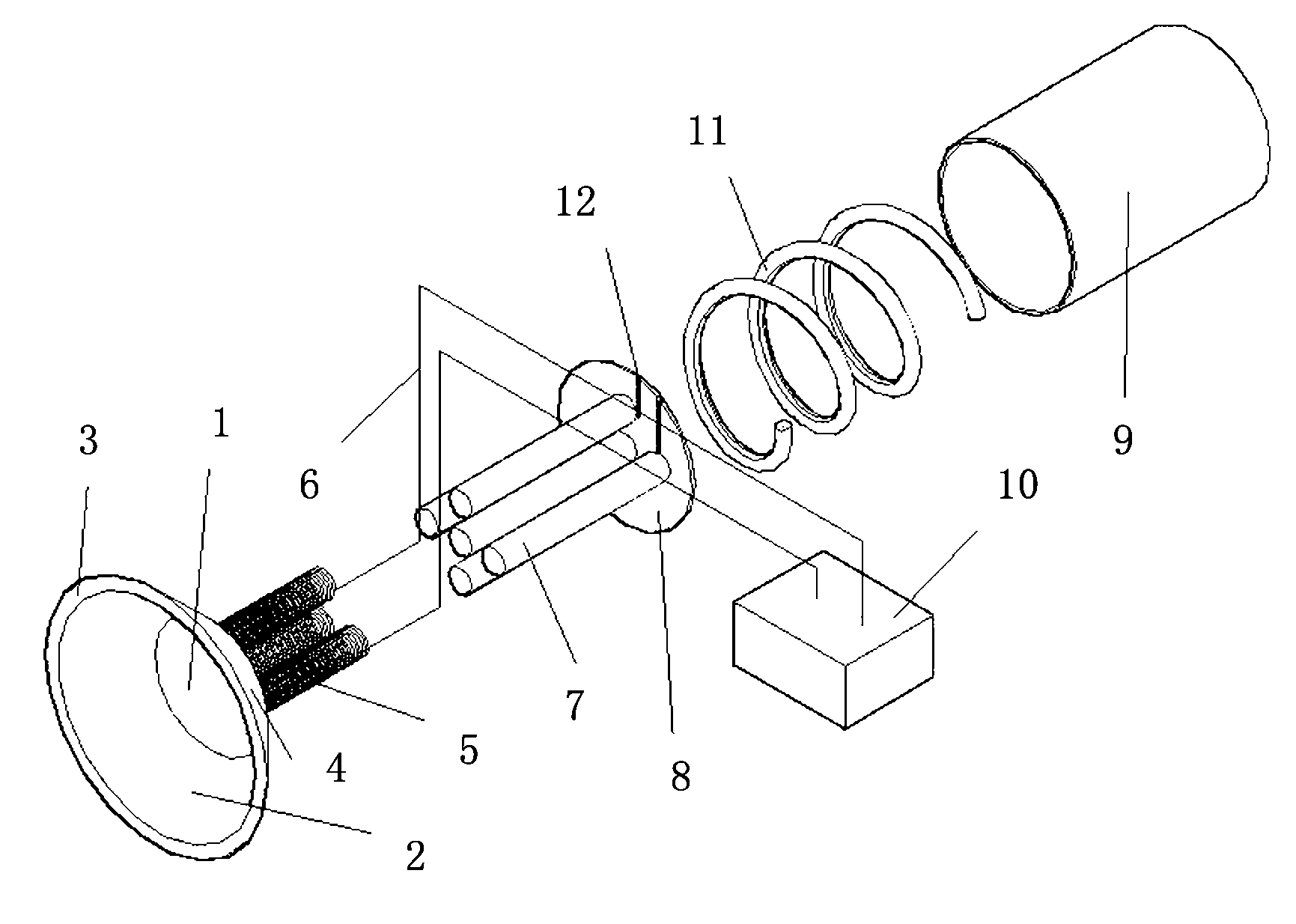

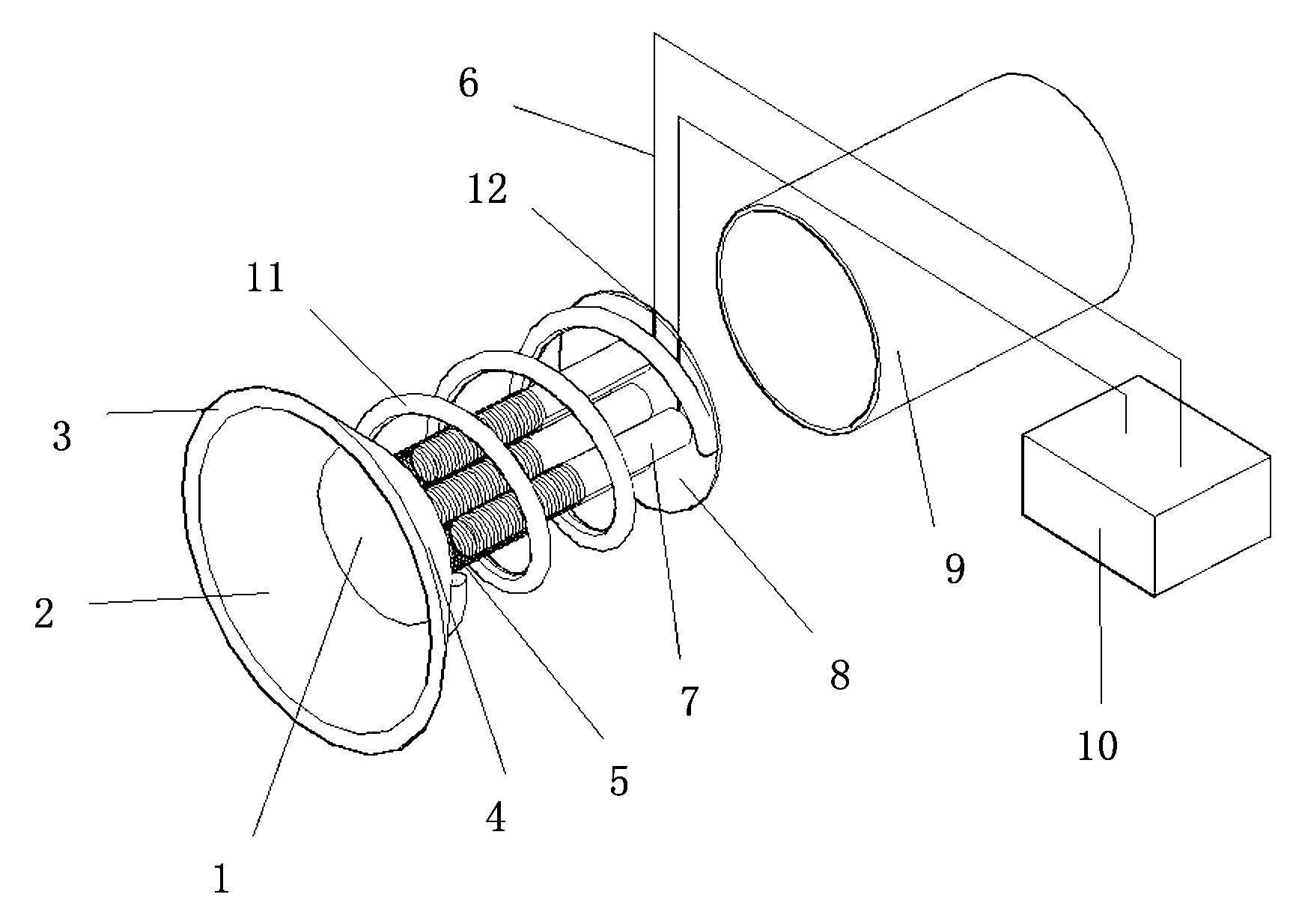

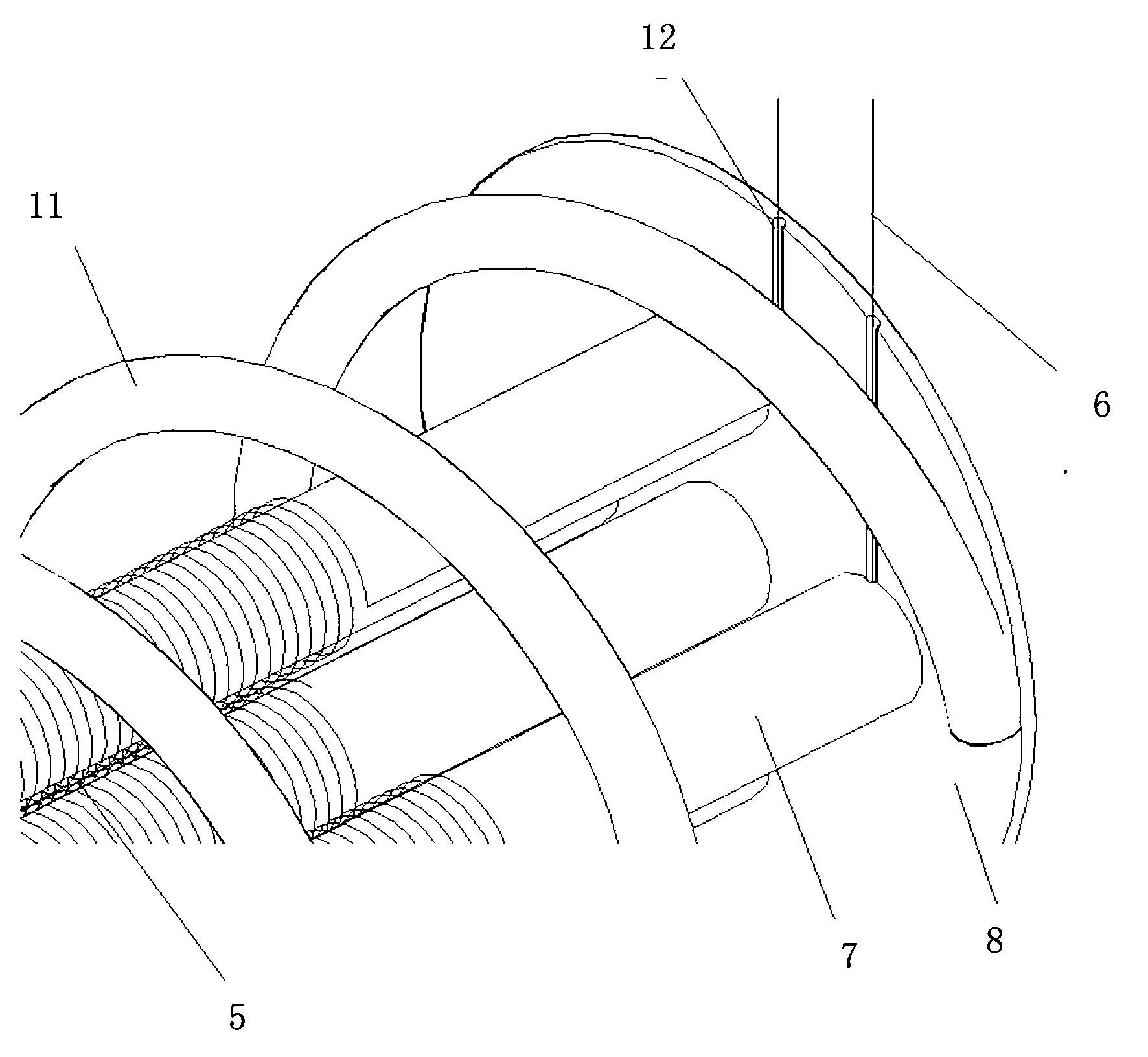

[0044] In areas with relatively high noise, such as an airport, multiple sound wave generators are installed on the metal plate, and the sound wave generators face the sound source. The paper cone 2 of the acoustic wave generator vibrates to a certain extent due to the action of sound energy such as noise, and then drives the synchronous vibration of the generating coil 5, so that the vibration of the generating coil 5 cuts the magnetic field lines of the magnet 7, and generates electrical energy. The generated electric energy is transmitted to the power transmission target device 10 through the power transmission wire 6 . Since a plurality of acoustic wave generators work together, the currents output by the plurality of acoustic wave generators can be fed into the same power transmission target device 10 . Then, the integration of the power transmission target device 10 is output to the power supply device.

Embodiment 2

[0046] The acoustic wave generator is arranged on or inside the shell of complex large-scale mechanical equipment without affecting the work of the mechanical equipment. The acoustic wave generator collects the noise emitted by the mechanical equipment, converts it into an electrical signal and outputs it to the power transmission target equipment 10, and provides computer analysis and processing, that is, compares the collected actual electrical signal with the reference electrical signal preset in the computer. The signals are compared, and the preset reference electrical signal is obtained by collecting and converting the mechanical equipment when it is working normally. Therefore, the characteristics of the actual electrical signal are analyzed by the computer to judge whether the mechanical equipment is working normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com