Multifunctional spread cooling sieve

A multi-functional, sieving technology, which is applied in tea treatment before extraction, etc., can solve the problems of high cost, low mechanization of tea classification, and low utilization rate of spreading space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

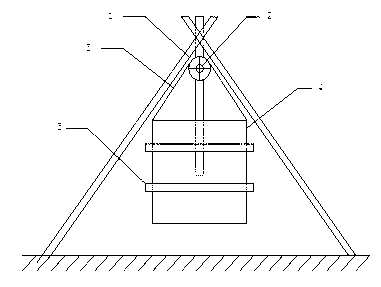

[0016] As shown in the figure, the multifunctional cooling screen of the present invention includes a combined cooling screen body 4 made of at least two layers of cooling screens and a suspension device for hanging the combined cooling screen body 4. The suspension device is a support frame 1, Preferably adopt the tripod support frame that is made up of three support rods, the tripod support frame is preferably a bamboo pole, utilizes the stability of triangle, keeps the stability of whole combined cooling screen body 4, to support the weight in the process of classifying and cooling, fully able to support Weight requirements in the processing process; the tripod support frame is provided with a pulley device 2, and the periphery of the combined cooling screen body 4 is provided with a stay rope 3 for hanging the combined cool screen body 4, and the stay rope 3 can be connected with the pulley device 2. Control the front and rear inclination angles of the combined cooling siev...

Embodiment 2

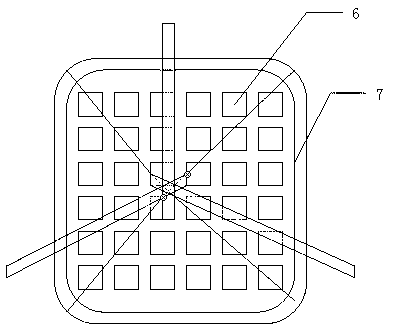

[0018] The combined cool sieve body 4 in this embodiment is made of three layers of cool sieves and is based on bamboo products as the main material, that is, the cool sieve is made of bamboo curtain strips, wherein there are many square sieves with certain dimensions on the bottom surface of each layer of cool sieves The meshes on the bottom surface of each layer of cooling screens are different in type (the square meshes from top to bottom are 2cm, 1.5cm, and 1cm in length respectively); the cooling screens made of bamboo curtain strips have high density and good toughness , high strength, strong and durable, not easy to deform, can keep cool and ventilated in the air, and at the same time play the function of effectively filtering the temperature and humidity inside and outside the sieve, to a certain extent solves the impact of weather on tea spreading, at the same time, Suspension device among the present invention can be selected as ceiling suspension, also can be selecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com