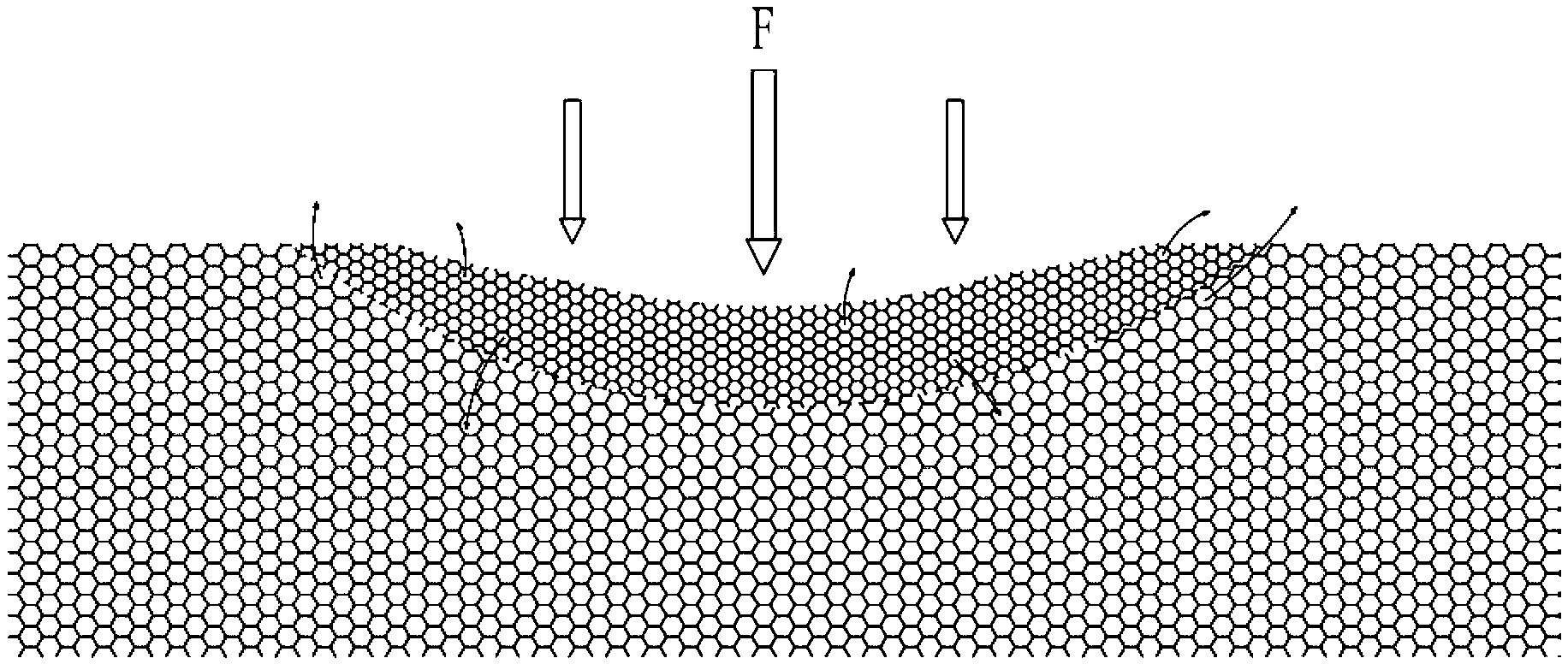

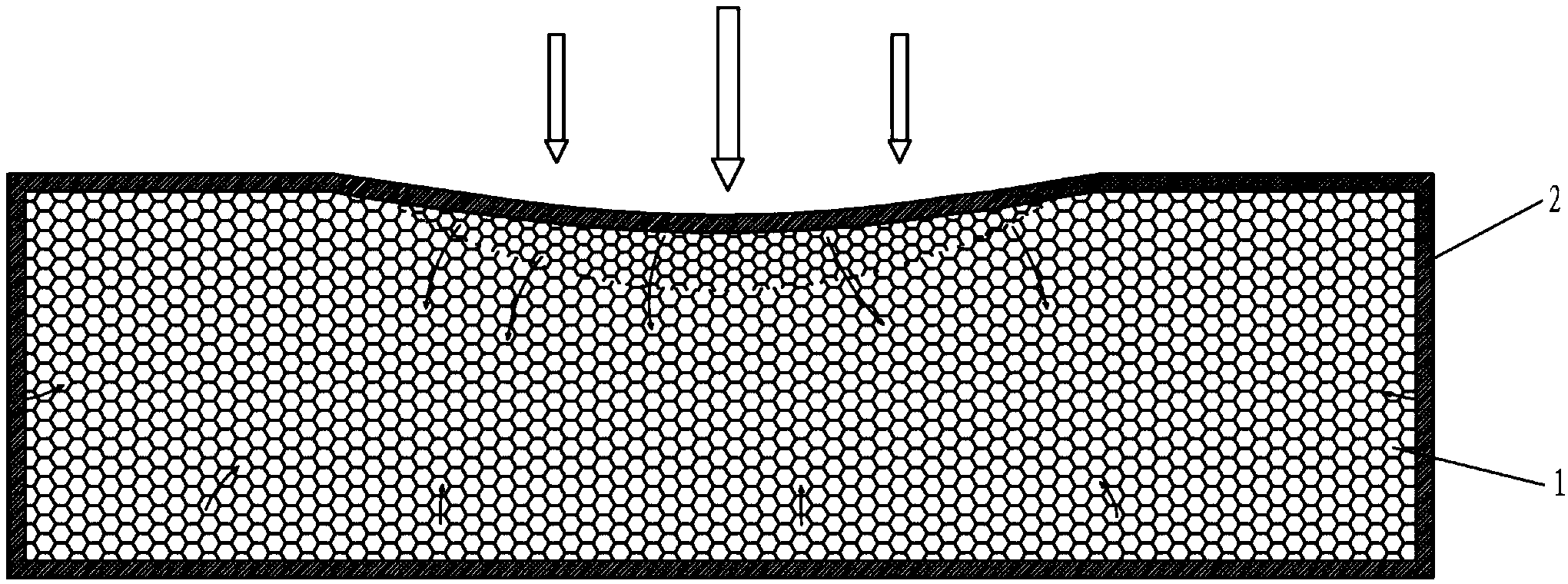

Damping structure with flexible airtight materials wrapping soft foaming materials in sealing mode

A technology of airtight materials and foam materials, which can be applied to shoe uppers, boot legs, clothing, etc., and can solve problems such as loss of shock absorption capacity and poor comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

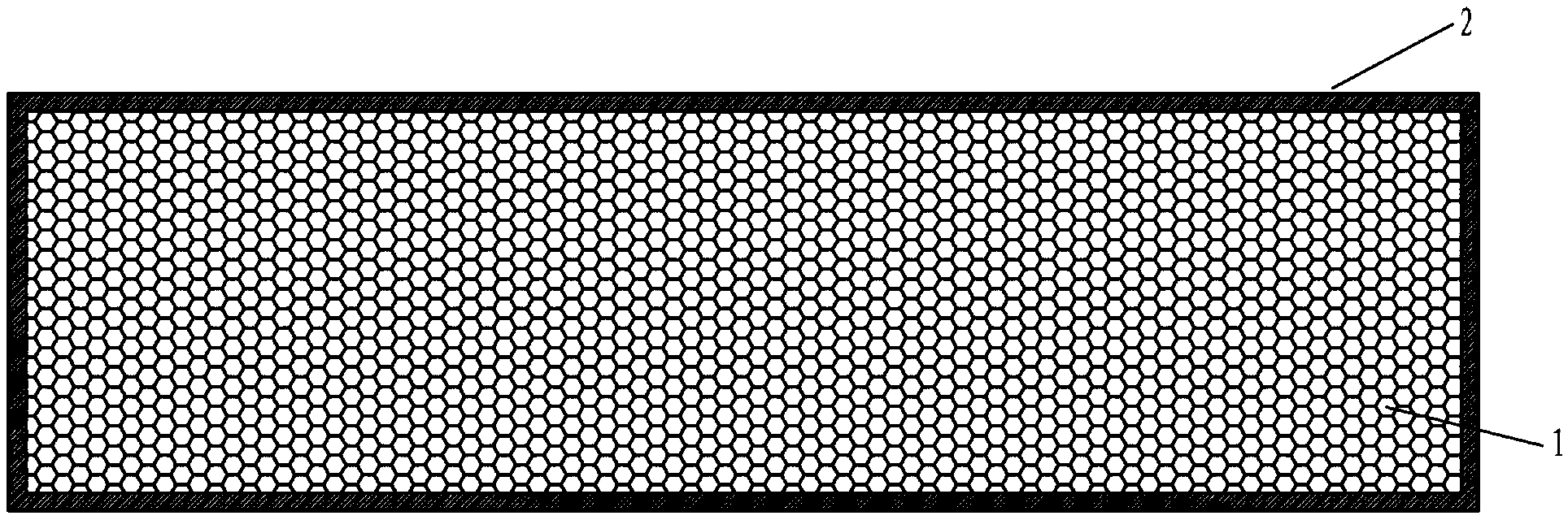

Embodiment 1

[0020] Embodiment 1: When the flexible airtight wrapping layer 2 of the present invention is nylon cloth, and the soft foam body 1 is soft polyurethane foam material, it is found through experiments that the performance parameters of the embodiment of the present invention are 2 times better than the prior art in terms of pressure resistance. times, the performance parameter rebound rate of the embodiment of the present invention is 1.7 times of the prior art.

Embodiment 2

[0021] Embodiment 2: When the flexible airtight wrapping layer 2 of the present invention is a rubber layer, and the soft foam 1 is an EVA elastic foam material, it is found through experiments that the performance parameter of the embodiment of the present invention is 2.5 times lower than that of the prior art. times, the performance parameter rebound rate of the embodiment of the present invention is 1.6 times of the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com