Scrap-free self-closing medical plastic combination plug

A self-closing, plastic technology, applied in the field of pharmaceutical packaging, can solve the problems of easy film cracking and peeling, human injury, foreign matter brought into the liquid, and achieve the effects of reasonable structure design, convenient use and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

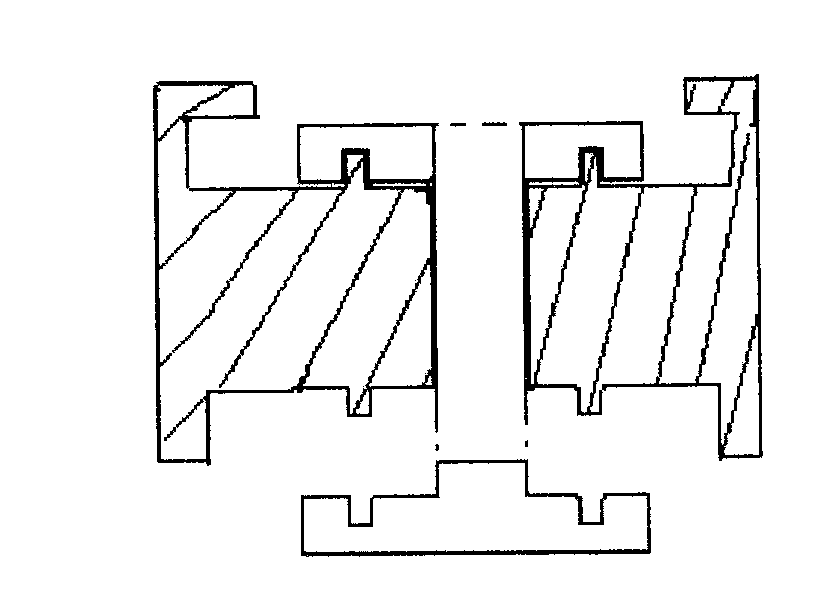

[0019] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further illustrate the present invention.

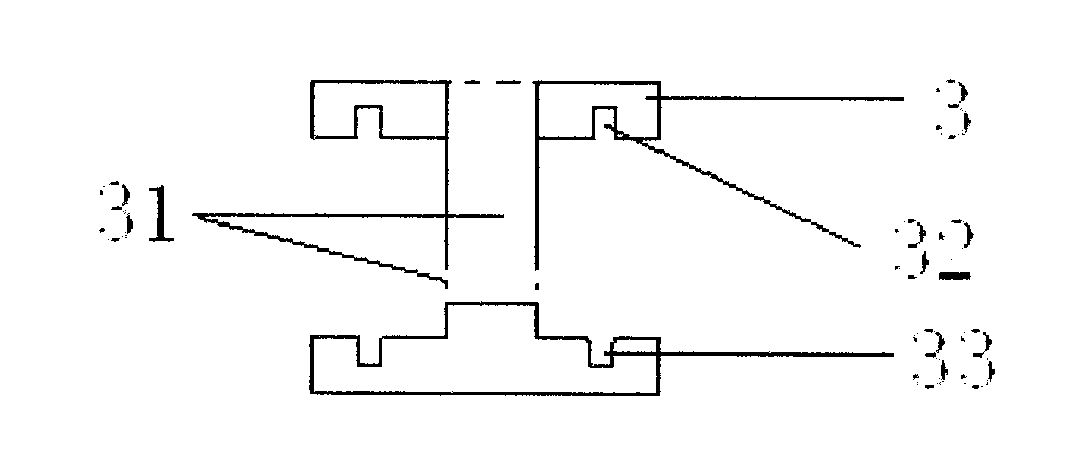

[0020] like figure 1 As shown, the piston body of the self-closing medical plastic composite plug without falling debris includes a piston body 3 , an inverted T-shaped liquid medicine flow channel 31 , an upper sealing groove 32 and a lower sealing groove 33 .

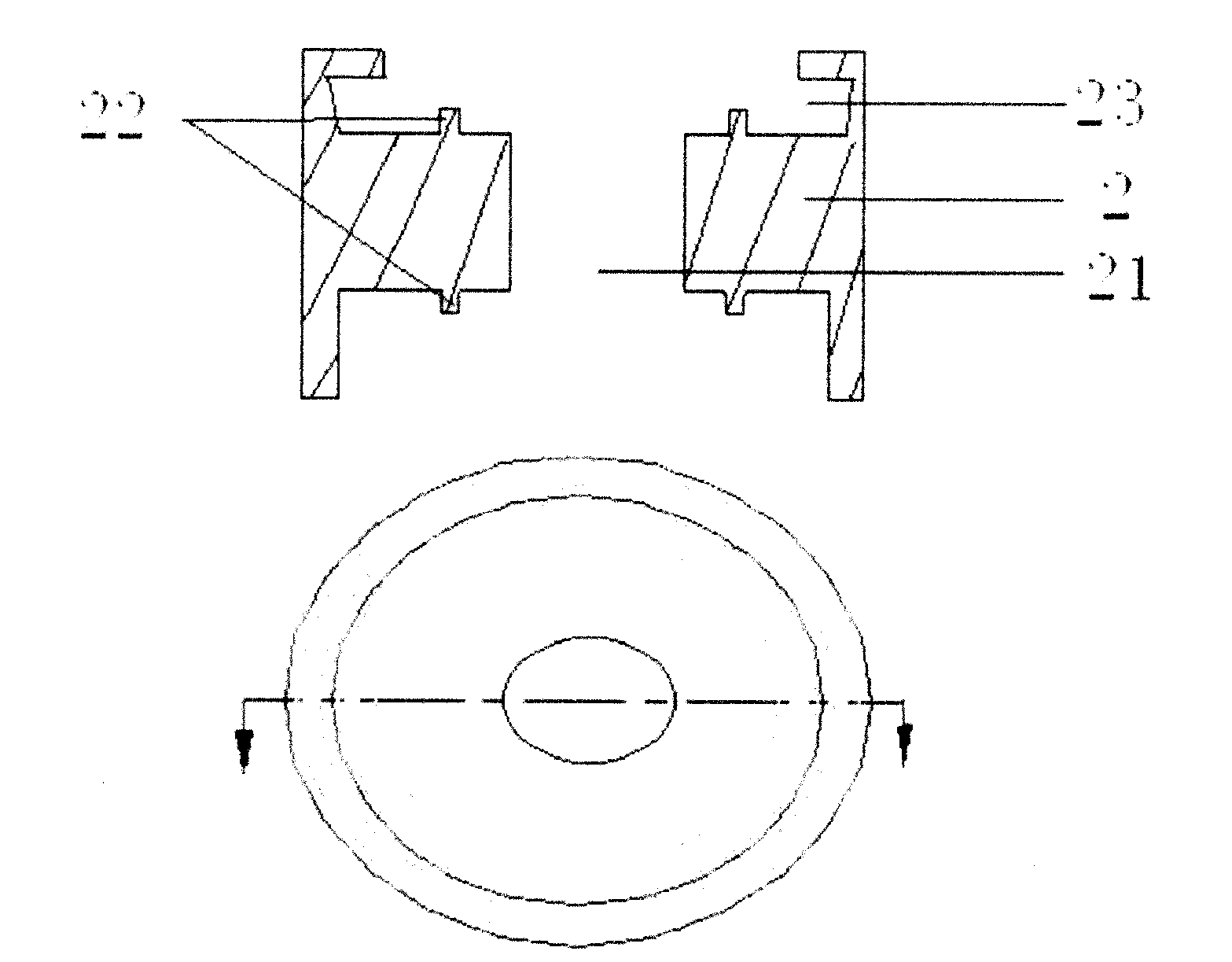

[0021] like figure 2 As shown, the lower plug body (not including the piston body) of the non-falling self-closing medicinal plastic composite plug includes the lower plug body 2, the piston body installation channel 21, the upper and lower sealing raised rings 22 and the embedded groove 23.

[0022] like image 3 As shown, the lower plug body (including the piston body) of the non-falling self-closing medicinal plastic composite plug is composed of the piston body 3 inserted into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com