Precision medicine liquid light-avoiding filter and manufacturing method thereof

A filter and liquid medicine technology, applied in the field of medical devices, can solve the problem of unsafe light-proof filters, and achieve the effects of improving connection firmness and stability, eliminating harm and having obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described.

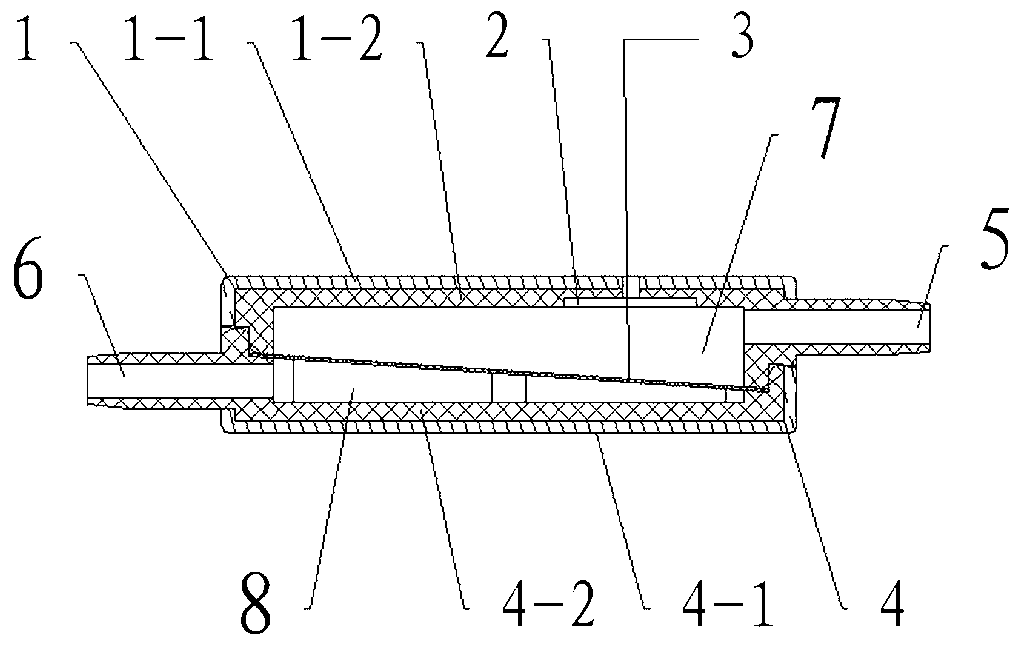

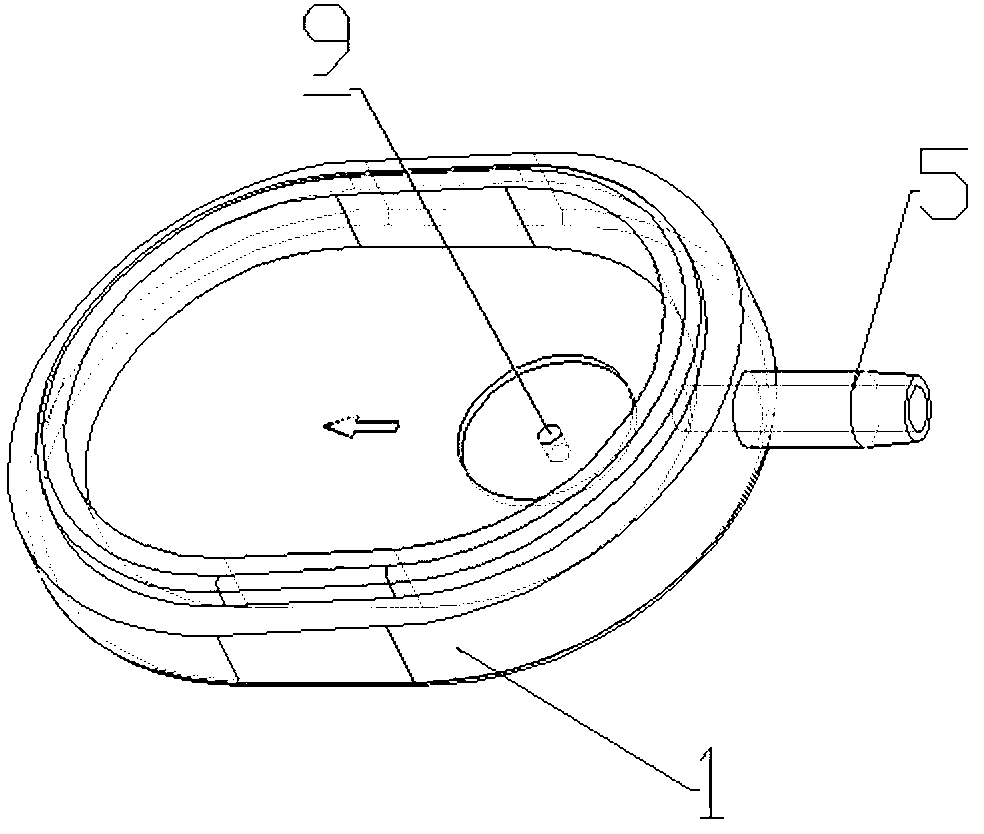

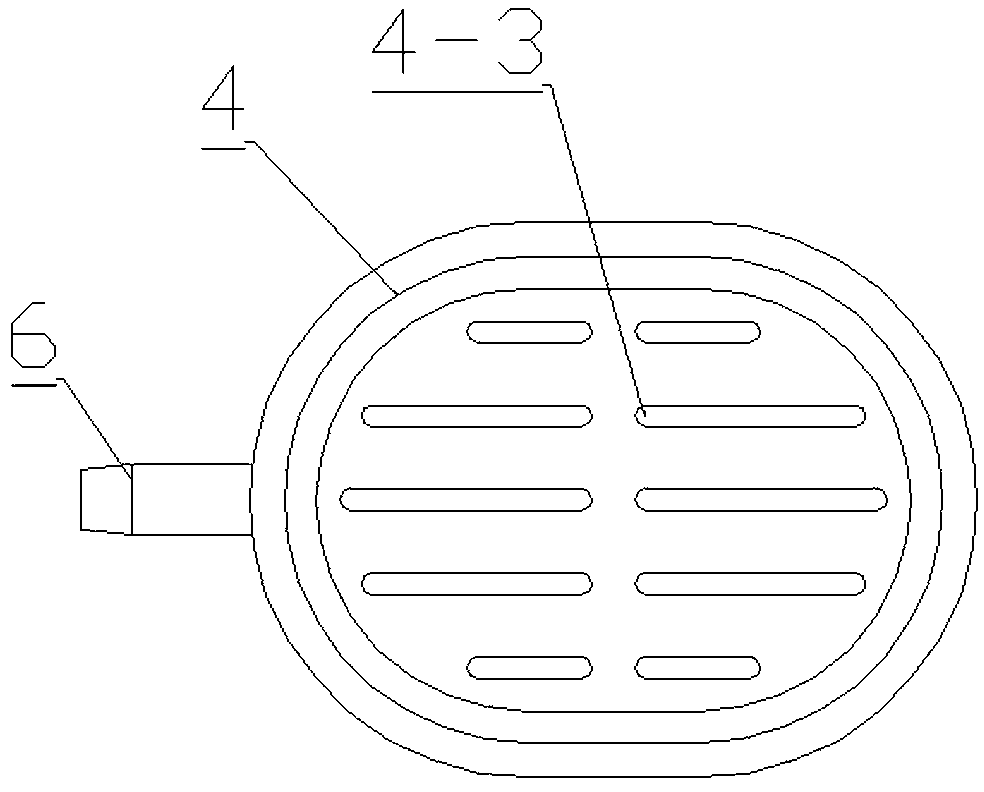

[0016] Such as figure 1 , figure 2 , image 3 As shown, the precision medicinal liquid light-proof filter of the present invention comprises a filter upper cover 1, a hydrophobic membrane 2, a filter lower cover 4, the filter upper cover 1 and the filter lower cover 4 are fastened and welded together, and the filter The upper cover 1 is formed by double-layer injection molding. The inner layer 1-2 of the upper cover is a colorless transparent layer in contact with the liquid medicine. There is a liquid inlet 5 on it, and an air outlet 9 is arranged on the filter upper cover 1. There can be one or more air outlets 9, preferably 2-8 in the present invention, and the inherent hydrophobic membrane 2 at the air outlet 9, the hydrophobic membrane 2 is welded on the inner wall of the filter upper cover 1 by an ultrasonic welding machine; the filter lower cover 4 is formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com