Sediment suction system for cloth media filter

A technology of suction system and filter cloth filter, which is applied in the field of water treatment, can solve the problem that filter cloth sludge and sundries cannot be thoroughly cleaned, and achieve the effect of reducing the cost of manual treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

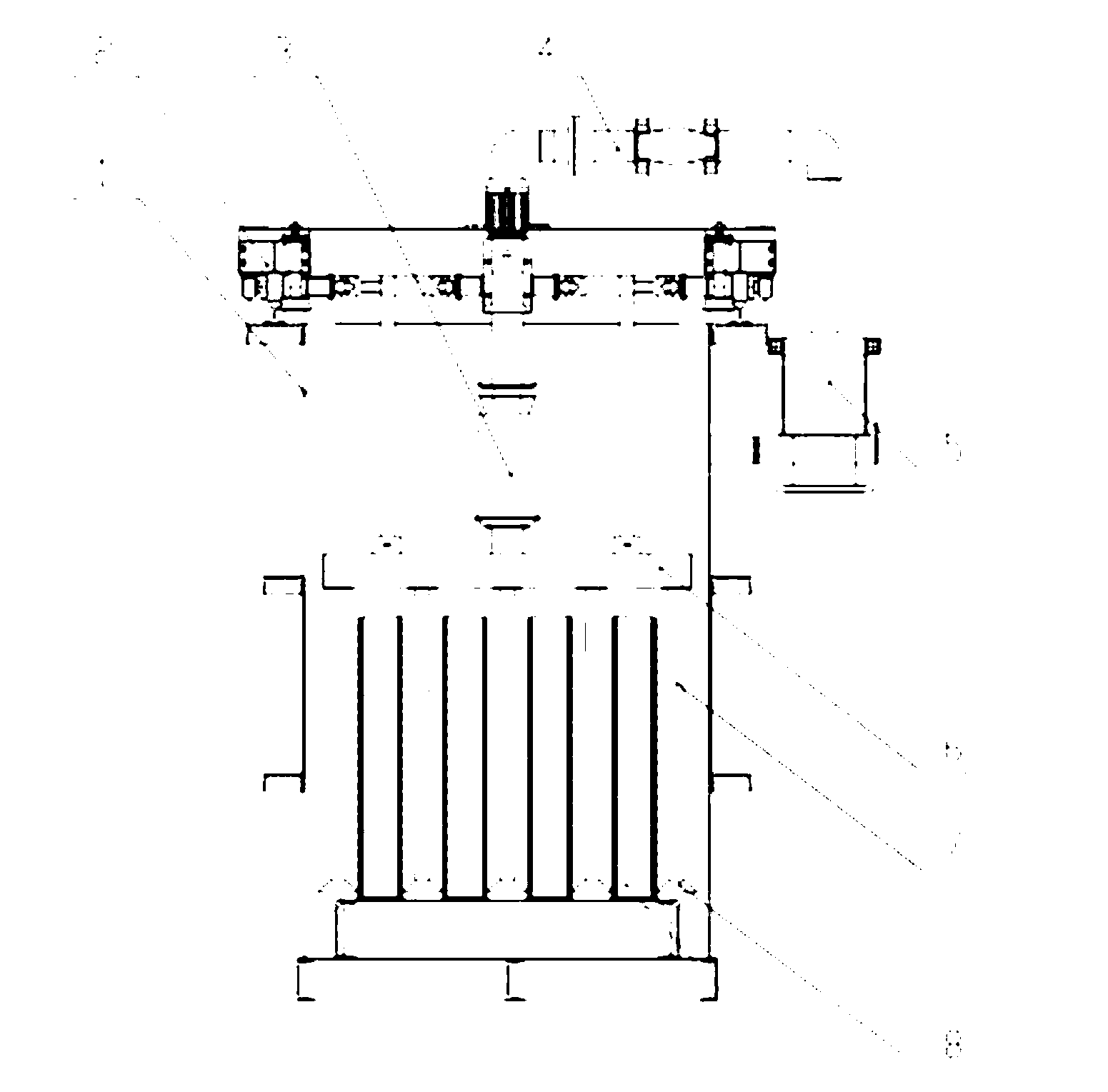

[0024] combine figure 1 and figure 2 Illustrate a kind of bottom mud suction system that is used for filter cloth filter tank of the present invention, bottom mud suction system comprises suction assembly, suction pump 3, driving mechanism and sludge discharge pipe 4; Suction assembly, suction pump 3 and the sludge discharge pipe 4 are connected in sequence, and the driving mechanism 2 is connected with the suction assembly, which is the power mechanism of the suction system to drive the bottom sludge suction system to run between the filter assemblies 9 to suck the bottom sludge and sundries.

[0025] Suction components include Shaped suction main pipe 6, several suction branch pipes 7 that are connected in parallel below the horizontal pipeline of suction main pipe 6 and communicate with it; One end of the sludge discharge pipe 4 communicates with the vertical pipeline of the suction main pipe 6, and the other end of the sludge discharge pipe 4 communicates with the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com