High-capacity centrifugal machine rotor and continuous flow centrifugal machine

A centrifuge rotor and large-capacity technology, which is applied in centrifuges and other directions, can solve the problems of low centrifugation efficiency, limited volume, and long centrifugation operation time, so as to improve centrifugation efficiency, shorten centrifugation operation time, and collect precipitated solids. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments. The given embodiments are only general illustrations of the present invention, which are helpful for a better understanding of the present invention, but do not limit the scope of the present invention.

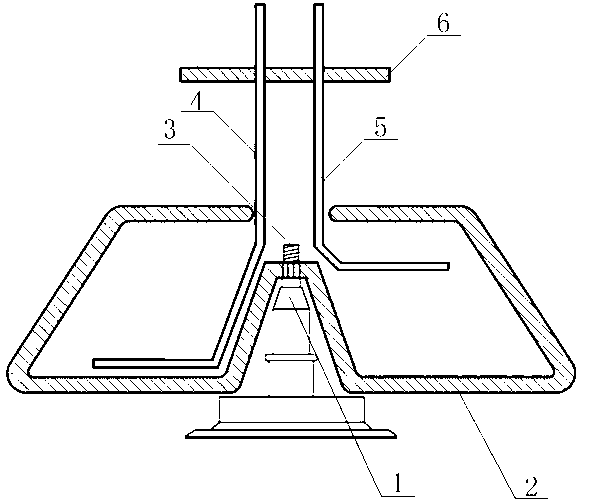

[0013] see figure 1 The large-capacity centrifuge rotor of the present invention includes a rotor 2, the rotor 2 is a hollow trapezoidal cylinder with an inlet and outlet hole in the center of the top, and the center of the bottom of the trapezoidal cylinder has a groove that is sunken inward. There is a shaft hole at the bottom of the groove, and the usual inlet and outlet holes are round holes, and the bottom of the groove is close to the inlet and outlet holes, so that the rotor 2 forms a structure similar to a trapezoidal ring cylinder. Specifically, the The rotor 2 is a central axis symmetrical structure. Through the design of this structure, duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com