Bonding wire cutting machine and bonding wire cutting control method

A control method and cutting machine technology, applied in the field of cutting machines, can solve the problems of personnel burns, welding explosions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

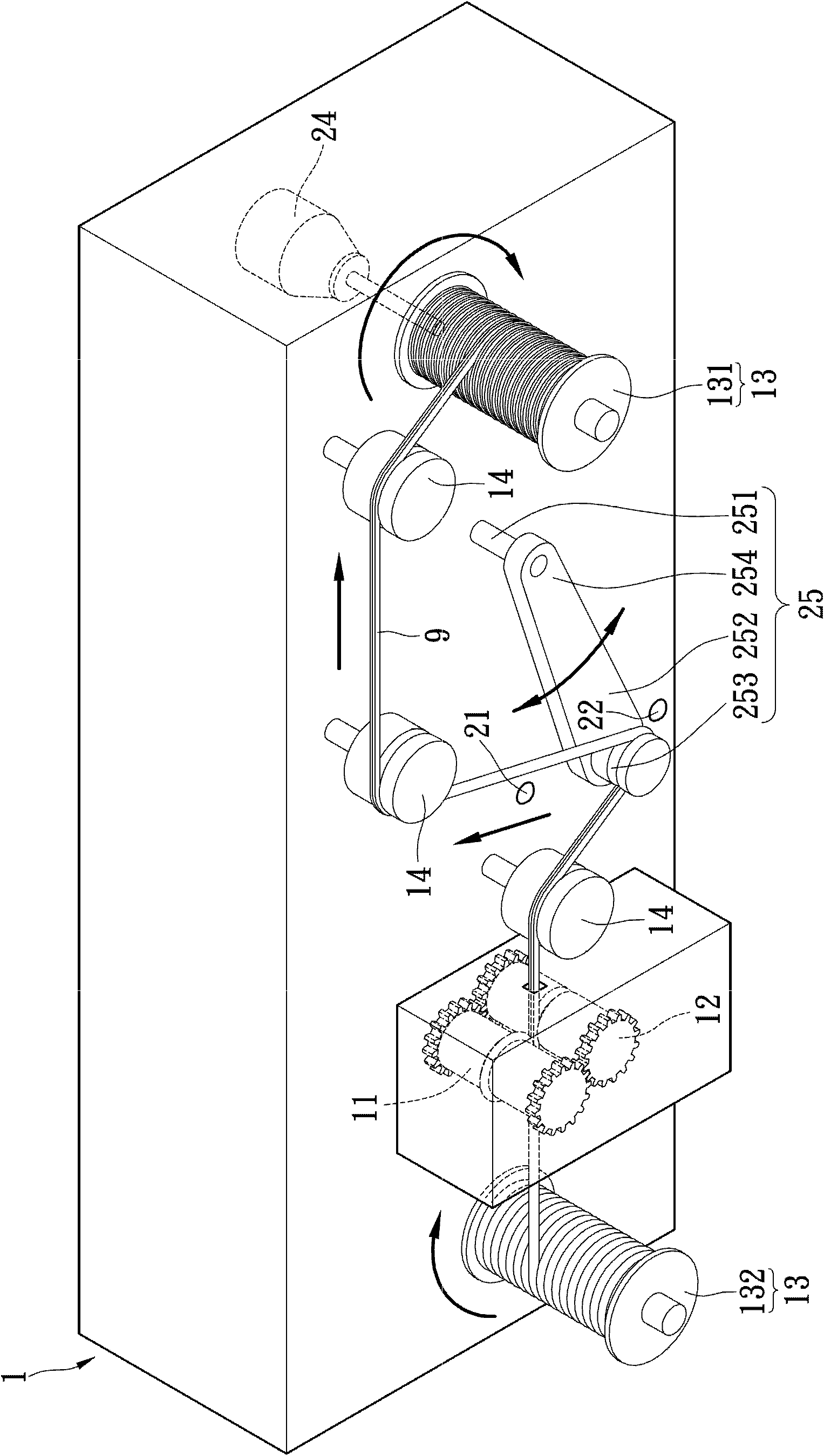

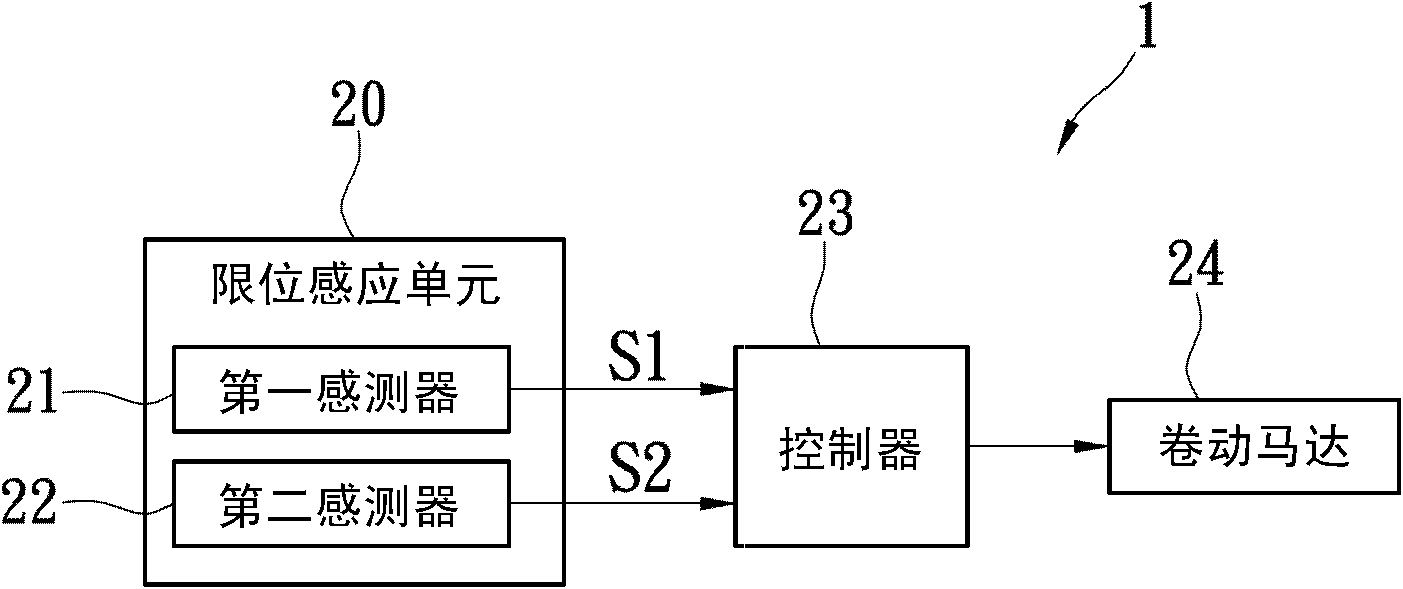

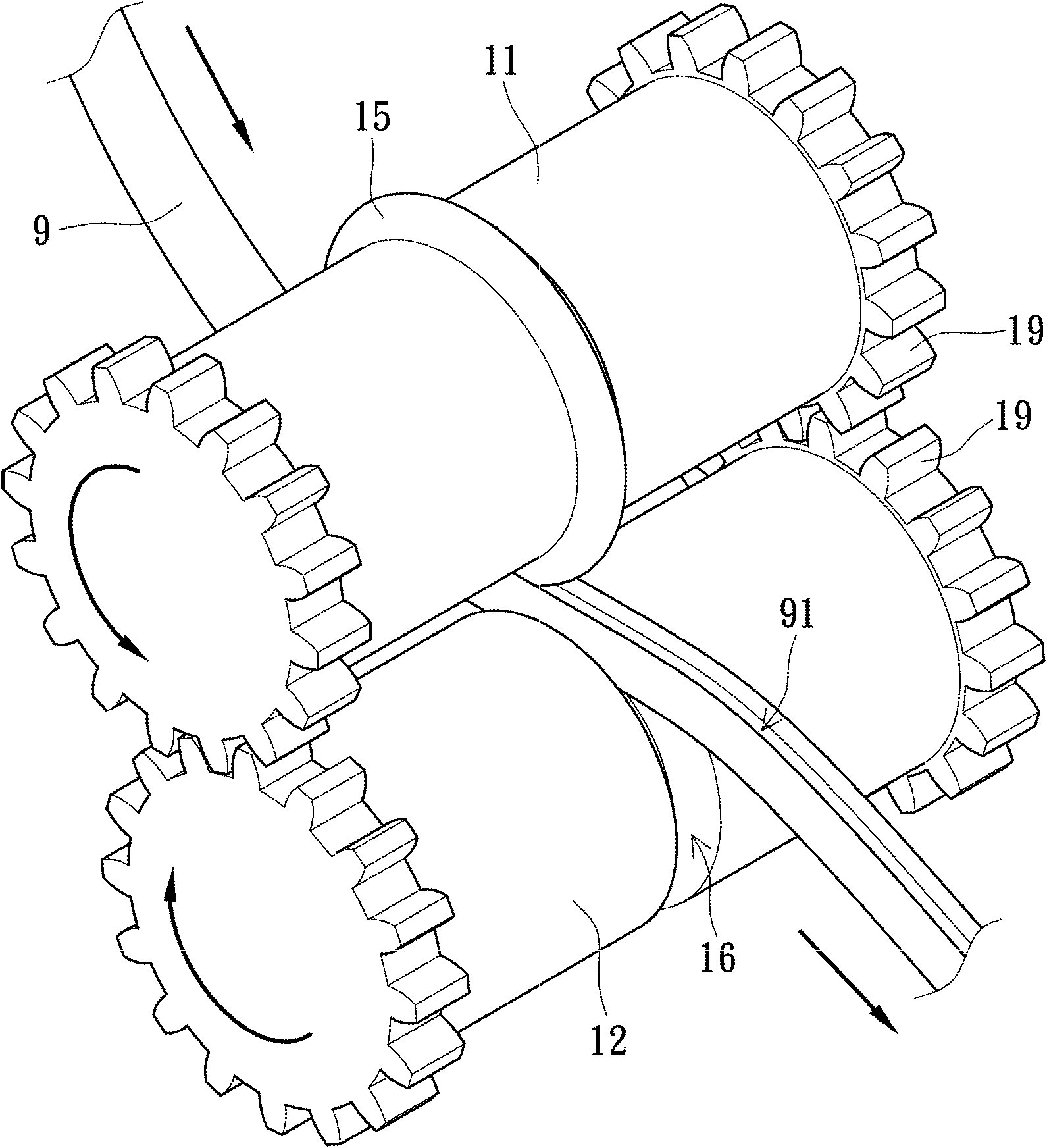

[0054] Please also see Figure 1A and figure 2 , Figure 1A It is a schematic diagram of the appearance of the welding wire cutting machine according to the first embodiment of the present invention, figure 2 It is a structural schematic diagram of the cutter, the first roller and the second roller according to the first embodiment of the present invention. Such as Figure 1A As shown, a welding wire cutting machine 1 is used for cutting a welding wire 9 into a groove 91 (shown in Figure 4 ), so that the groove 91 forms a groove surface. Traditionally, the welding wire 9 is made of soft metal or alloy with a low melting point, so generally speaking, the welding wire 9 is mostly made of tin wire (or tin wire) made of tin metal or tin alloy. The main choice. The wire cutting machine 1 includes a scrolling unit 13 , a cutter 15 , an adjusting arm 25 , a first sensor 21 , a second sensor 22 , a scrolling motor 24 and a plurality of roller units 14 . Wherein, the rolling uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com