Method for gas replacement before brazing of small-scale gas cylinder

A gas replacement and gas cylinder technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of bottle confusion, bottle scrapping, brazing furnace cooling down, parking and troubleshooting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

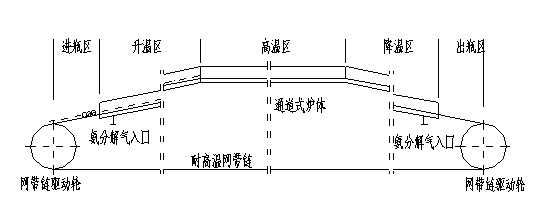

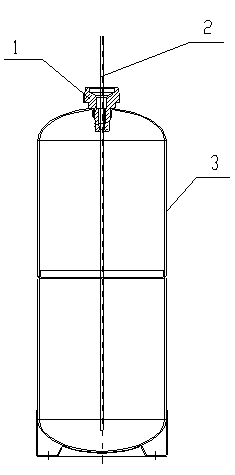

[0015] A gas replacement method before brazing of a small gas cylinder: after the bottle body is assembled, it is carried out before being placed on the high-temperature-resistant mesh belt chain in the bottle-entry area of a channel-type atmosphere protection brazing furnace. Such as figure 2 shown, including the following steps:

[0016] 1) Remove the assembled bottle body 3 from the conveying line.

[0017] 2) Put the bottle body 3 upright.

[0018] 3) Insert the slender nozzle 2 of the air gun from the 3.5mm hole on the valve seat 1 to the bottom of the bottle body 3.

[0019] 4) Turn on the switch of the gas filling gun, put the inert gas under pressure into the bottle body 3, turn off the gas filling gun after a few seconds and pull it out from the hole.

[0020] 5) Place the bottle body 3 that has completed the gas replacement on the high-temperature-resistant mesh belt chain in the bottle-entry area of the channel-type atmosphere protection brazing furnace.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com