Battery cooling group, electric automobile air conditioner system and electric automobile

A technology for electric vehicles and air-conditioning systems, which is applied in the direction of electric vehicles, secondary batteries, and the arrangement of the cooling combination of power plants, etc. It can solve problems such as poor anti-vibration performance, inconvenient installation in the car, and broken connection tubes, and improve work efficiency. Reliability, shorten assembly time, reduce the effect of connecting piping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The core of the present invention is to provide a battery cooling group with compact structure, easy installation, relatively good anti-vibration performance and relatively low cost of use. In addition, another core of the present invention is to provide an electric vehicle air conditioning system and an electric vehicle including the above-mentioned battery cooling group.

[0036] Without loss of generality, this paper takes the application of the battery cooling group in electric vehicles as an example to introduce its technical solution and technical effect. Examples further illustrate the present invention in detail.

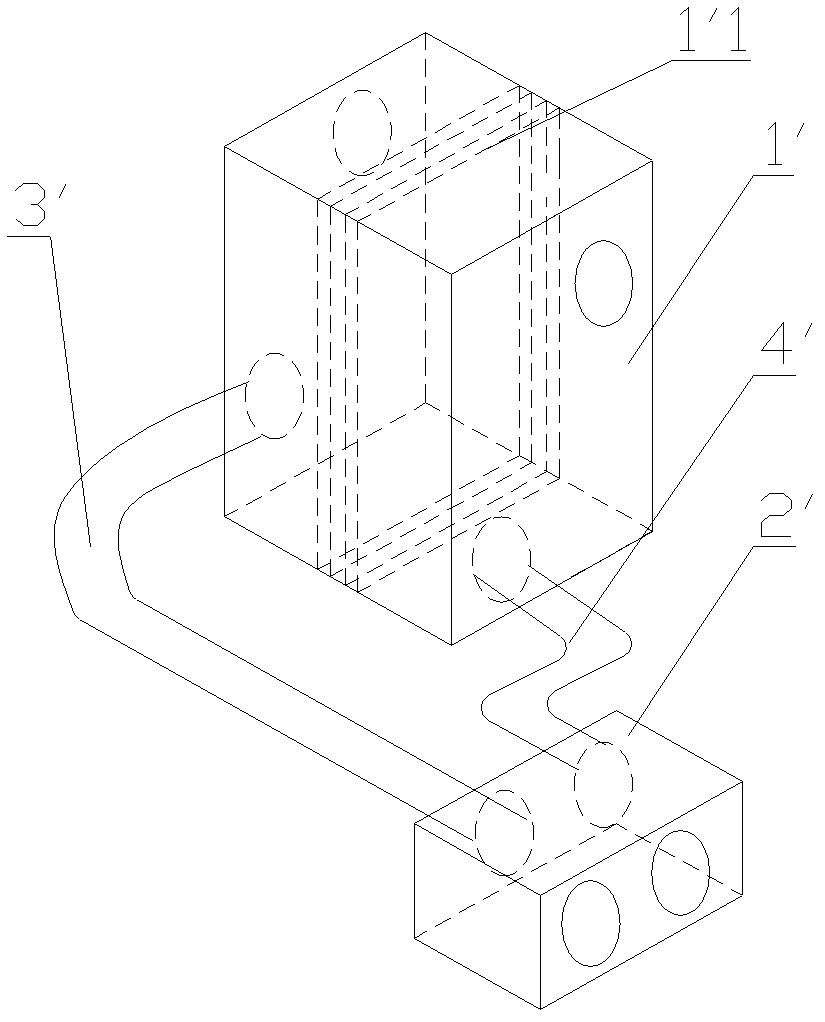

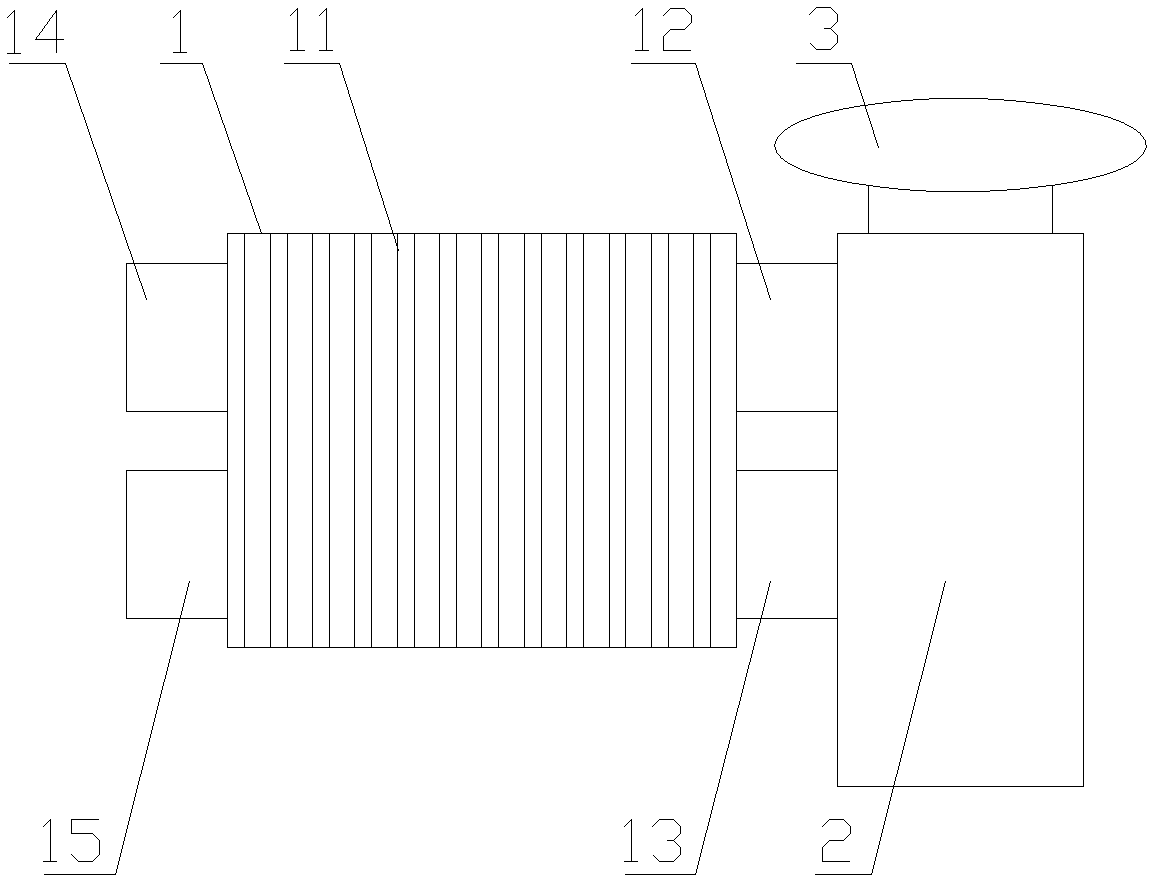

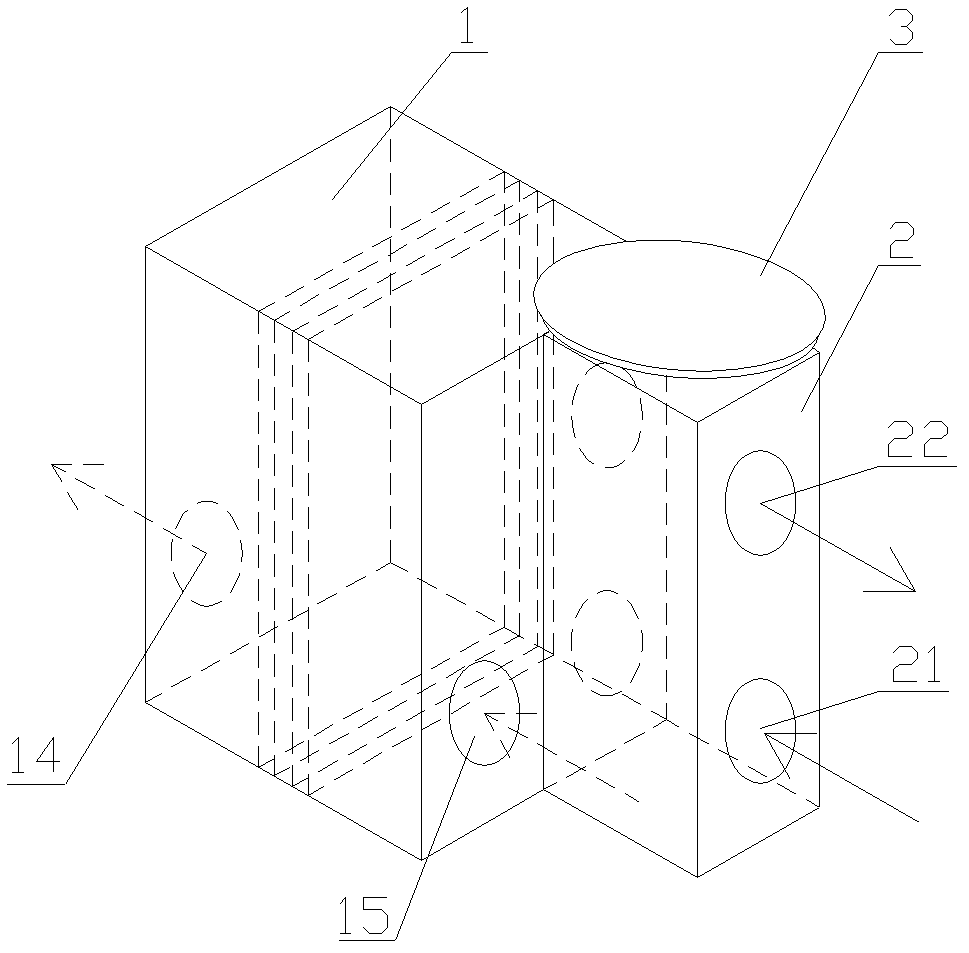

[0037] Please combine figure 2 with Figure 7 As shown, the cooling of the battery 7 used in the electric vehicle mainly uses a battery cooling group. The battery cooling group provided by the present invention includes a plate heat exchanger 1 and a thermal expansion valve 2. The plate heat exchanger 1 generally consists of a series of The corrug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com