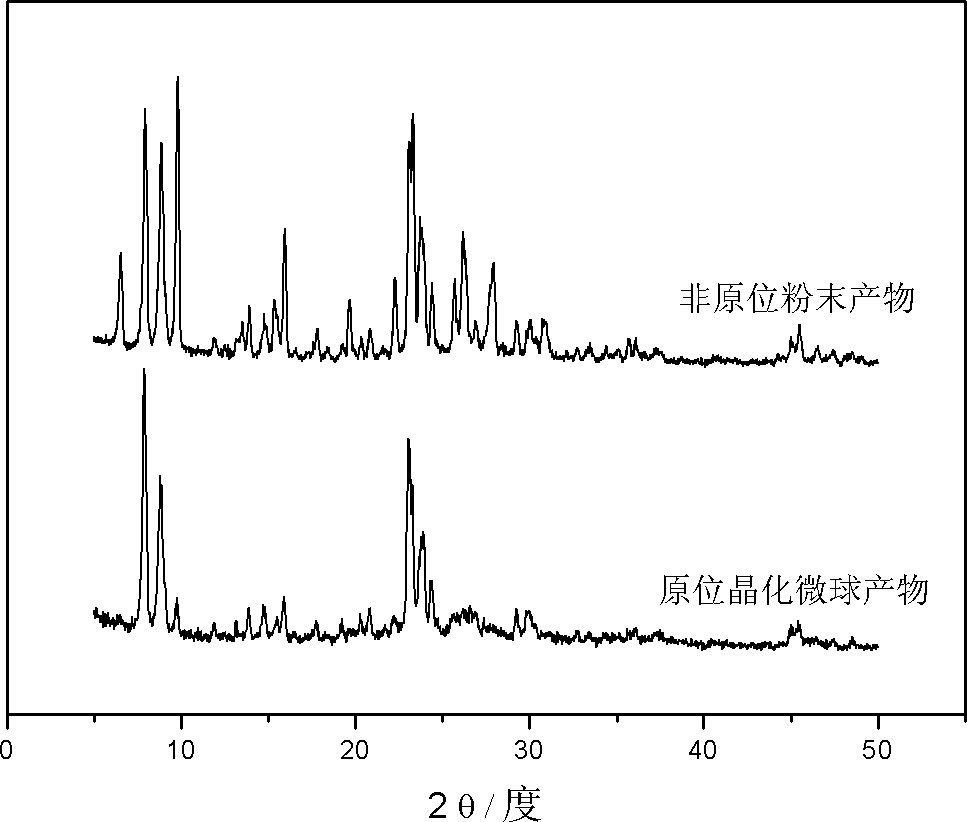

Method of in-situ crystallized synthesis of ZSM-5/mordenite compound

A technology of ZSM-5 and mordenite, which is applied in the direction of mordenite crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of long high temperature crystallization time and the like, Achieve the effect of low cost, developed pore structure and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

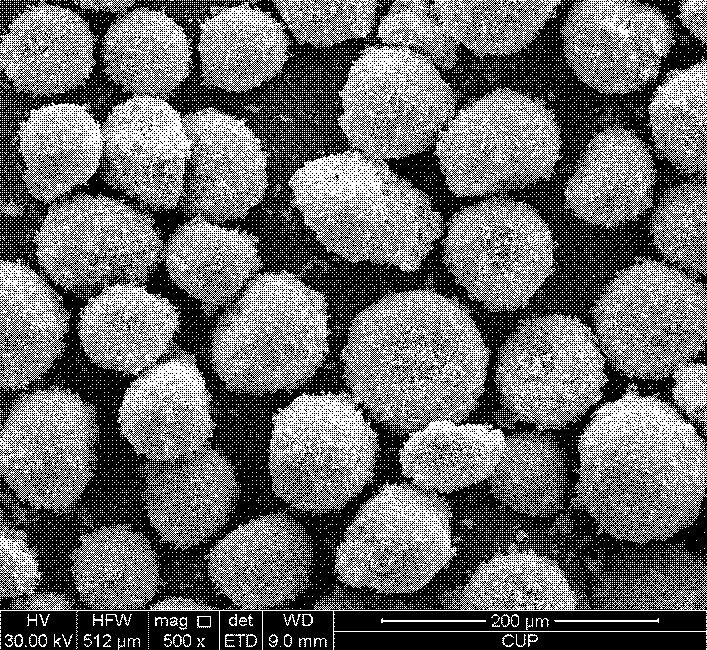

[0064] Preparation of kaolin microspheres:

[0065] 3071g of kaolin, 199g of ZSM-5 molecular sieve seeds, 536g of water glass and 5002g of distilled water were mixed and beaten, then spray-dried to prepare kaolin microspheres with a particle size of 10-210um. The kaolin microspheres were calcined at 950°C for 2 hours to obtain the calcined kaolin microspheres, the active SiO2 in the calcined kaolin microspheres 2 Content is 40.0wt%, active Al 2 o 3 Content 5.95wt%.

[0066] Synthesis of ZSM-5 / mordenite composite by in situ crystallization:

[0067] (1) Pretreatment of kaolin microspheres: Weigh 30.0g of roasted kaolin microspheres and 161.1g of distilled water in a beaker, put the beaker in a 90°C water bath, stir for 5min; add 111.1g of water glass into the beaker, and stir for 20h ;

[0068] (2) Preparation of the initial reactant: add 161.1g of distilled water to the above mixing system, after stirring for 10min, slowly add 31.1g concentration of 3M sulfuric acid solut...

Embodiment 2

[0072] Preparation of kaolin microspheres:

[0073] 2752g of kaolin, 183g of mordenite seed crystals, 263g of water glass and 4698g of distilled water were mixed and beaten, then spray-dried to prepare kaolin microspheres with a particle size of 10-210um. The kaolin microspheres were calcined at 950°C for 2 hours to obtain the calcined kaolin microspheres, the active SiO2 in the calcined kaolin microspheres 2 The content is 40.2wt%, active Al 2 o 3 Content 5.92wt%.

[0074] Synthesis of ZSM-5 / mordenite composite by in situ crystallization:

[0075] (1) Pretreatment of kaolin microspheres: Weigh 30.0g of roasted kaolin microspheres and 240.0g of distilled water in a beaker, put the beaker in a 60°C water bath, stir for 5min; add 64.2g of water glass into the beaker, and stir for 20h;

[0076] (2) Preparation of the initial reactant: add 240.0g distilled water to the above mixing system, after stirring for 10min, slowly add 10.0g concentration in the system and be 3M sulfuri...

Embodiment 3

[0080] Preparation of kaolin microspheres:

[0081] 3012g of kaolin, 99g of ZSM-5 molecular sieve seed crystals, 100g of mordenite zeolite seeds, 780g of water glass and 6206g of distilled water were mixed and beaten, then spray-dried to produce kaolin microspheres with a particle size of 10-210um. The kaolin microspheres were calcined at 950°C for 2 hours to obtain the calcined kaolin microspheres, the active SiO2 in the calcined kaolin microspheres 2 The content is 41.2wt%, active Al 2 o 3 Content 5.7wt%.

[0082] Synthesis of ZSM-5 / mordenite composite by in situ crystallization:

[0083] (1) Pretreatment of kaolin microspheres: Weigh 30.0g of roasted kaolin microspheres and 155.0g of distilled water in a beaker, put the beaker in a 70°C water bath, stir for 5min; add 92.5g of water glass into the beaker, and stir for 24h;

[0084] (2) Preparation of the initial reactant: add 155.0g distilled water to the above-mentioned mixed system, after stirring for 10min, slowly add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com