Microwave leakage prevention device for microwave oven

A technology of microwave ovens and microwaves, which is applied in the directions of household stoves/stoves, household heating, heating fuel, etc. It can solve problems such as microwave leakage, human injury, and complex production processes, so as to improve heating efficiency, reduce the amount of microwaves, and protect Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

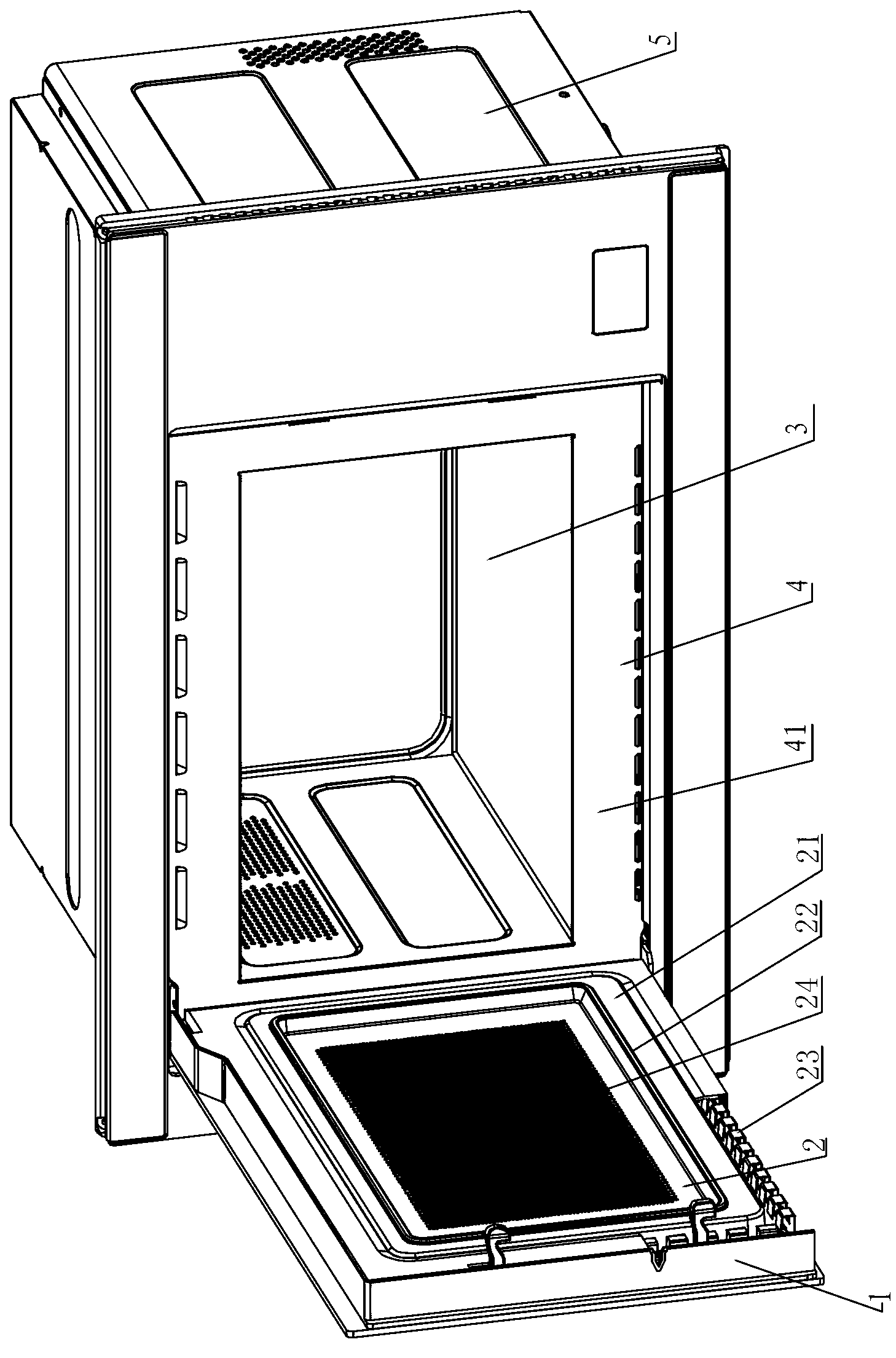

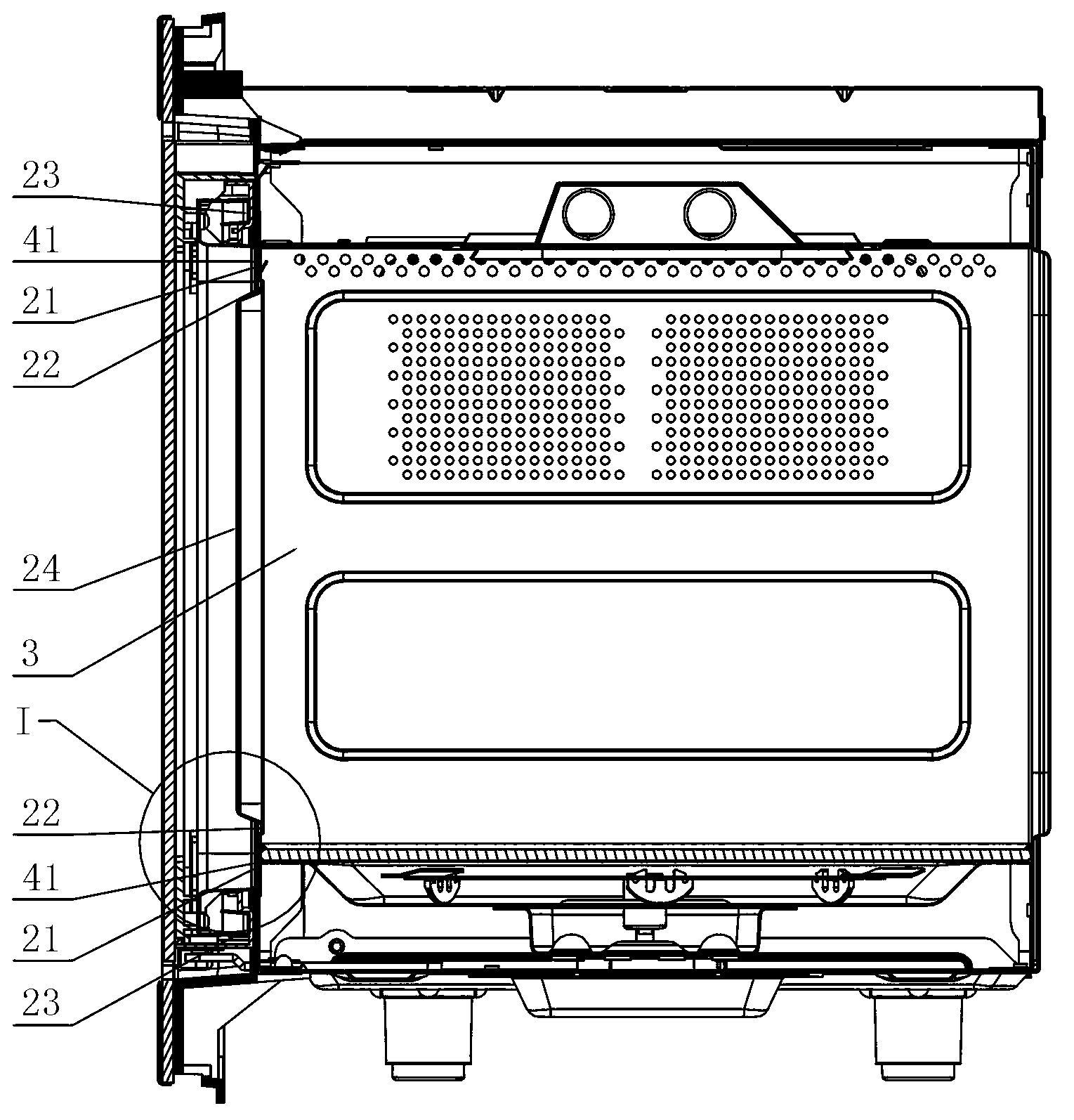

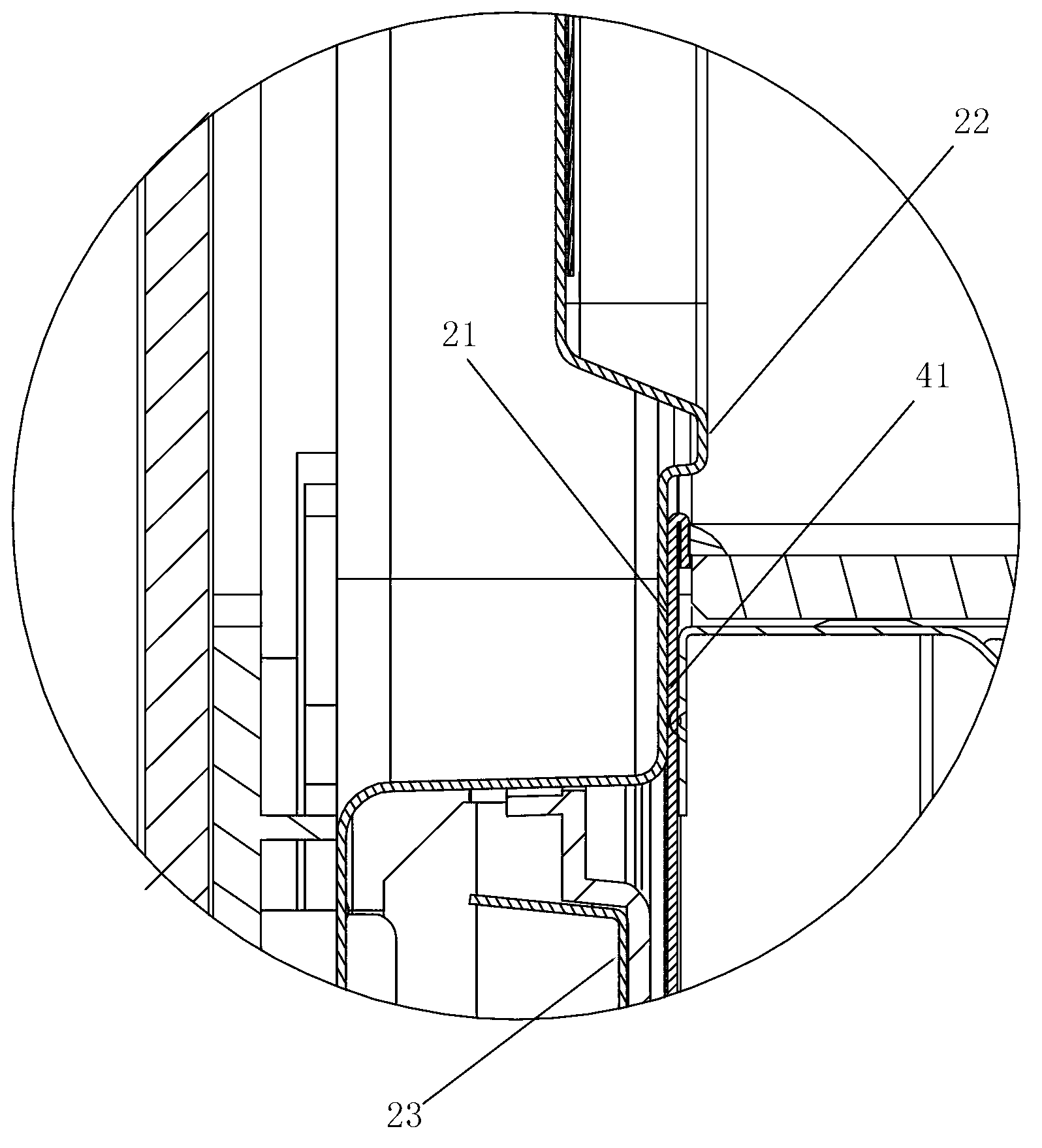

[0028] like Figures 1 to 4 The shown microwave oven includes: a furnace body 5, the middle of the furnace body 5 is a cooking chamber 3, the furnace body 5 is located at the entrance of the cooking chamber 3 and has a front plate 4 that defines the shape of the entrance, and the furnace body 5 is provided with a high-frequency For the microwave generator, the front side of the furnace body 5 is provided with a furnace door 1 for opening and closing the entrance of the cooking chamber 3; The shielding plate 2 is formed, and the shielding plate 2 has a contact portion 21 which is arranged to be opposed to an opposite portion of the front plate 4 of the furnace body 5 when the furnace door 1 is closed, and can be The opposite parts are closely attached, the outer circumference of the shielding plate 2 is provided with choke grooves 23, the middle part of the shielding plate 2 is provided with a certain number of small through holes 24, and the furnace body front plate that fits ...

Embodiment 2

[0032] The difference from the first embodiment is that the boss-type microwave blocking structure is: a boss 42 disposed on the front plate 4 and located on the periphery of the contact portion 21 and the sealing plane perimeter 41 when the furnace door 1 is closed. , the height of the boss 42 is at least 1mm higher than the sealing plane peripheral ring 41 . see Figures 5 to 7 shown.

Embodiment 3

[0034] Different from the first embodiment, the boss-type microwave blocking structure further includes: a boss disposed on the front plate 4 and located on the periphery of the contact portion 21 and the sealing plane perimeter 41 when the furnace door 1 is closed. 42, the height of the boss 42 is at least 1mm higher than the sealing plane peripheral ring 41. see Figures 8 to 10 shown. The design of the boss on the front plate 4 forms a microwave reflection surface, which can shield and reduce the amount of microwaves entering the choke groove 2-C. Compared with the first embodiment, a layer of microwave leakage protection is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com