A battery box for electric power system

A power system and battery box technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as difficulty in assembling batteries without interfering with each other, quality problems in parts, and difficulty in connecting terminals, etc. Simple, reduce the market damage rate, and the effect of clear wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

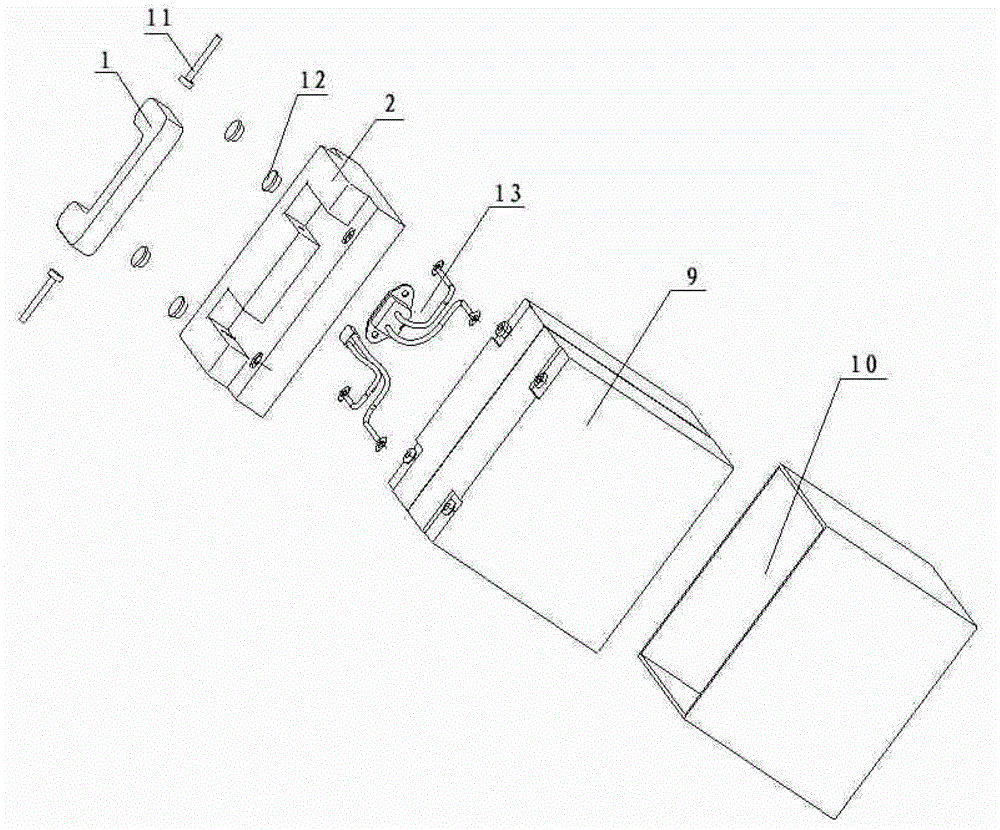

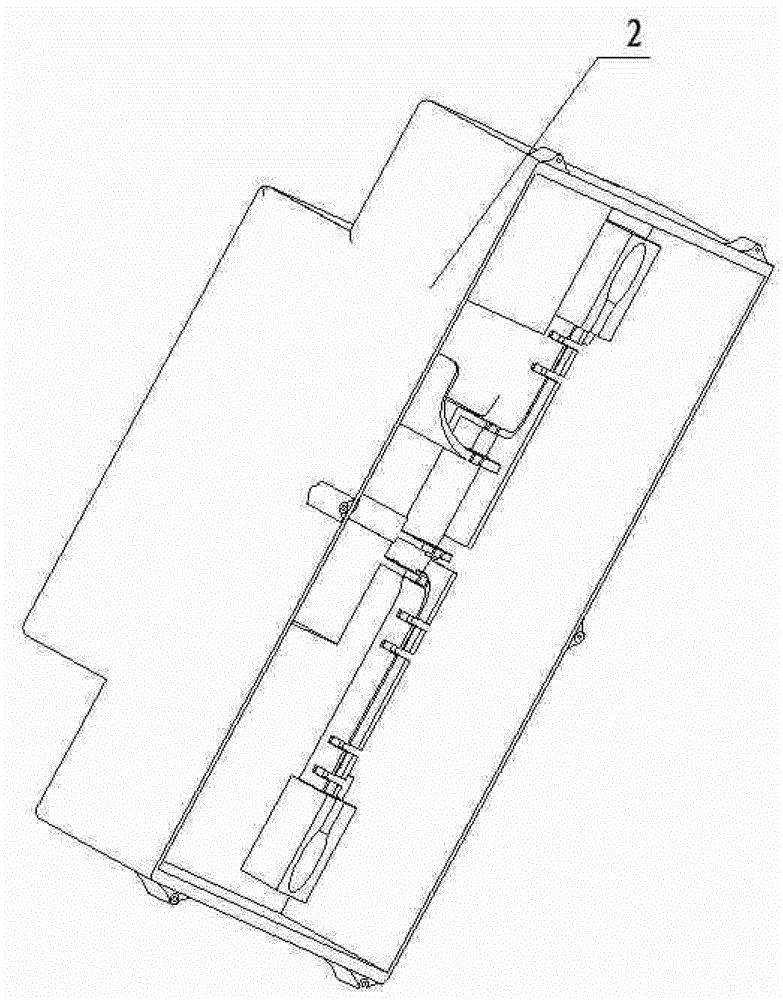

[0019] Figure 1 to Figure 5 As shown, it is a battery box for an electrical power system, including a battery box handle 1 assembled into one, a battery box upper cover 2, a power connection part 13, a battery 9 and a battery box bottom 10; the battery box The upper cover 2 is provided with a card slot structure for ferruling the power connection part 13; the power connection part 13 is detachably snapped into the card slot structure; the conductive screw provided sequentially connects the battery The upper cover terminals uniformly arranged on the box upper cover 2, the power connection terminals of the power connection part 13, and the battery connection terminals of the battery 9 are correspondingly assembled together. Wherein, the battery box handle 1 and the battery box upper cover 2 are assembled together through pins 11 . In addition, a waterproof sealing cover 12 may be provided on the upper cover terminal.

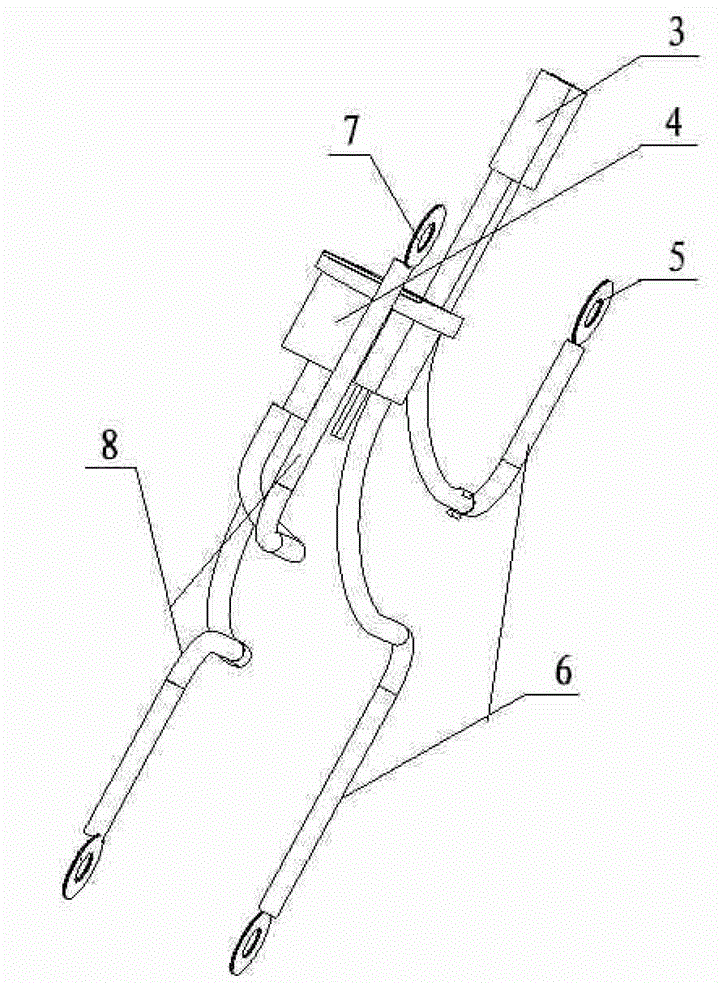

[0020] image 3 As shown, the power connection part 13 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com