Method and control device for automatically reducing reactive power before decommissioning of large combined cycle units

A combined cycle unit and control device technology, applied in control systems, reactive power compensation, control generators, etc., can solve problems such as severe voltage fluctuations, sudden changes in power grid power conditions, etc., to prevent sudden changes in power conditions, ensure normal work, prevent The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

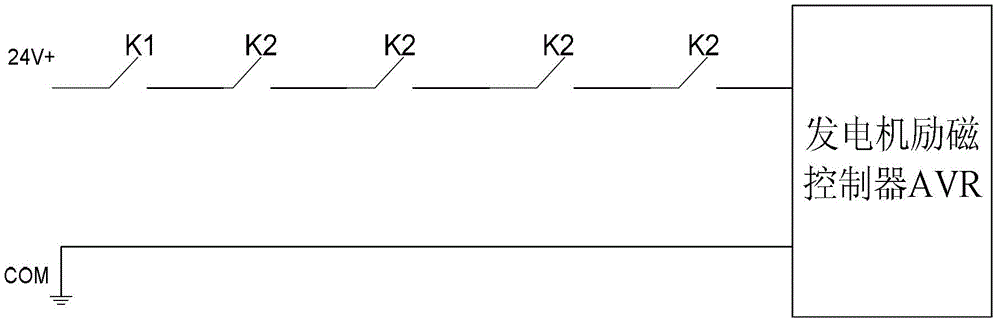

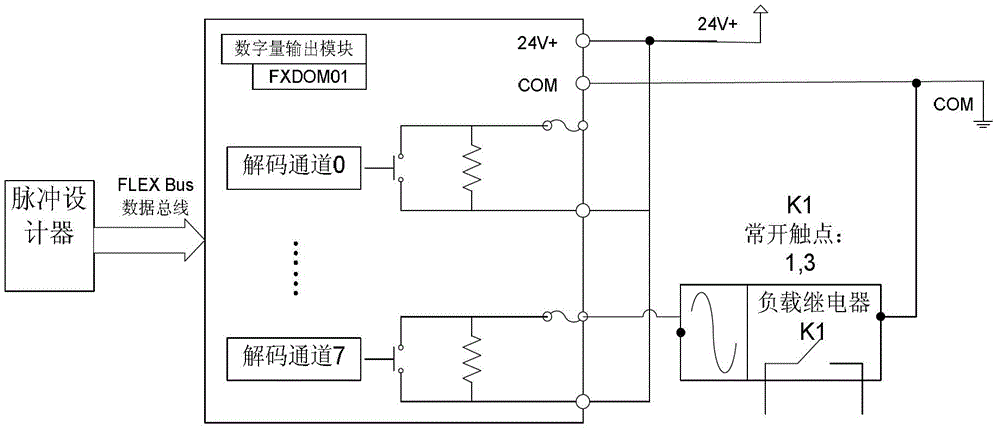

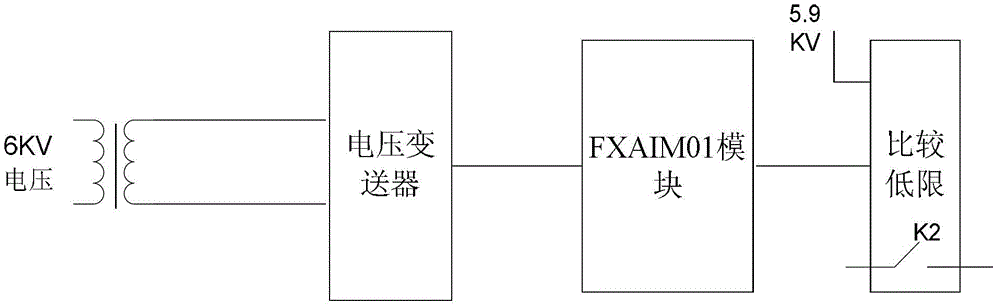

[0033] refer to figure 1, the control device for automatically reducing reactive power before the large-scale combined cycle unit decommissioning involved in this embodiment includes a distributed control system DCS, a detection loop, and a generator excitation controller AVR. Terminal voltage detection terminal, active power detection terminal and reactive power detection terminal, the output terminal of the detection circuit is connected to the input terminal of the distributed control system DCS, the output terminal of the distributed control system DCS is connected to the control input terminal of the generator excitation controller AVR, and the generator excitation The output terminal of the controller AVR is connected to the input terminal of the excitation system of the generator set. The distributed control system DCS first detects the shutdown command signal, and then detects the generator power terminal voltage, active power detection terminal and reactive power detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com