Switch reluctance motor without bearings

A switched reluctance motor and bearingless technology, which is applied in the direction of electrical components, magnetic attraction or thrust holding devices, etc., can solve the problems of low power density of the motor, difficulty in completely decoupling, low utilization of windings, etc., and achieve motor suspension Good performance, simple control method, high-speed adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

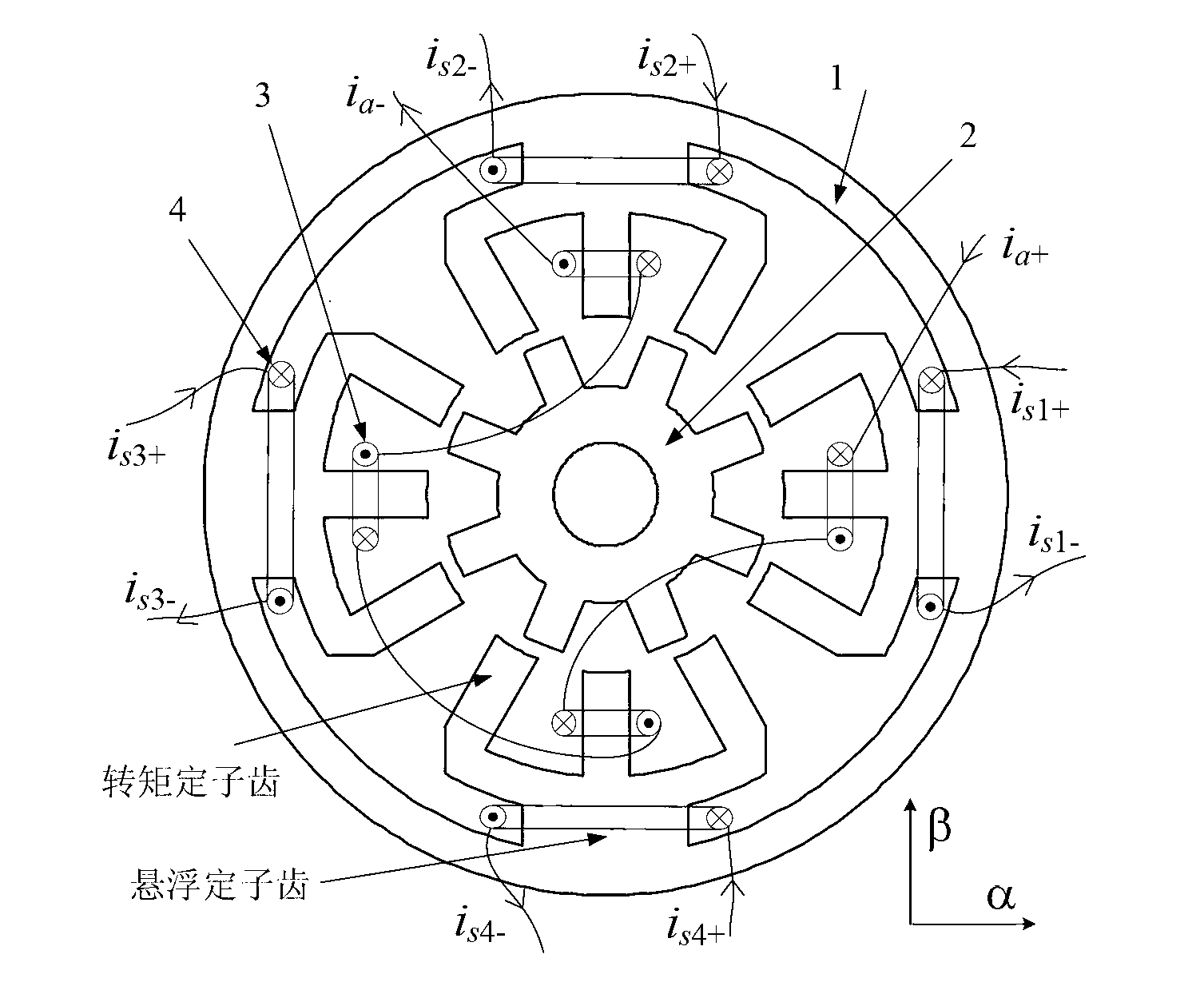

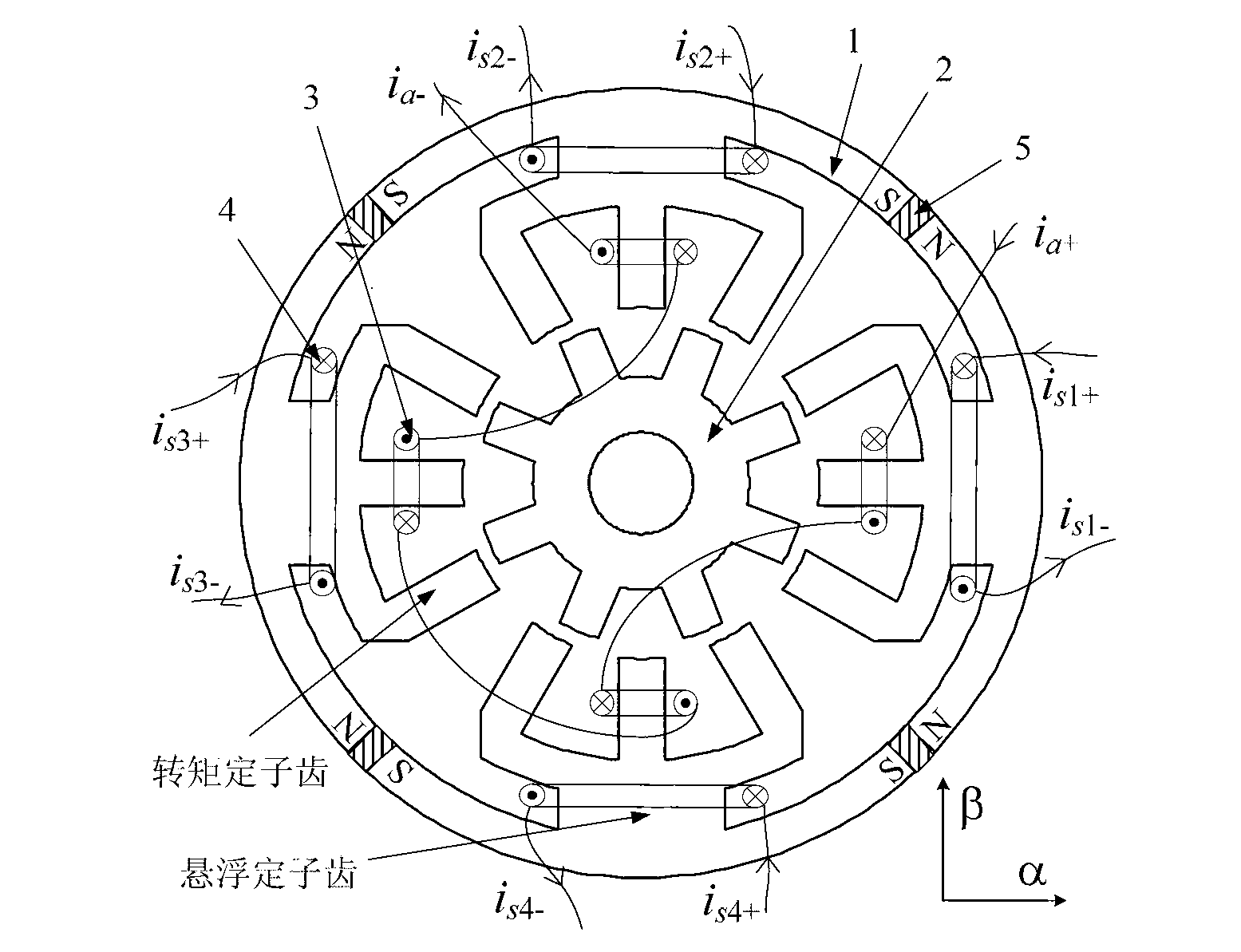

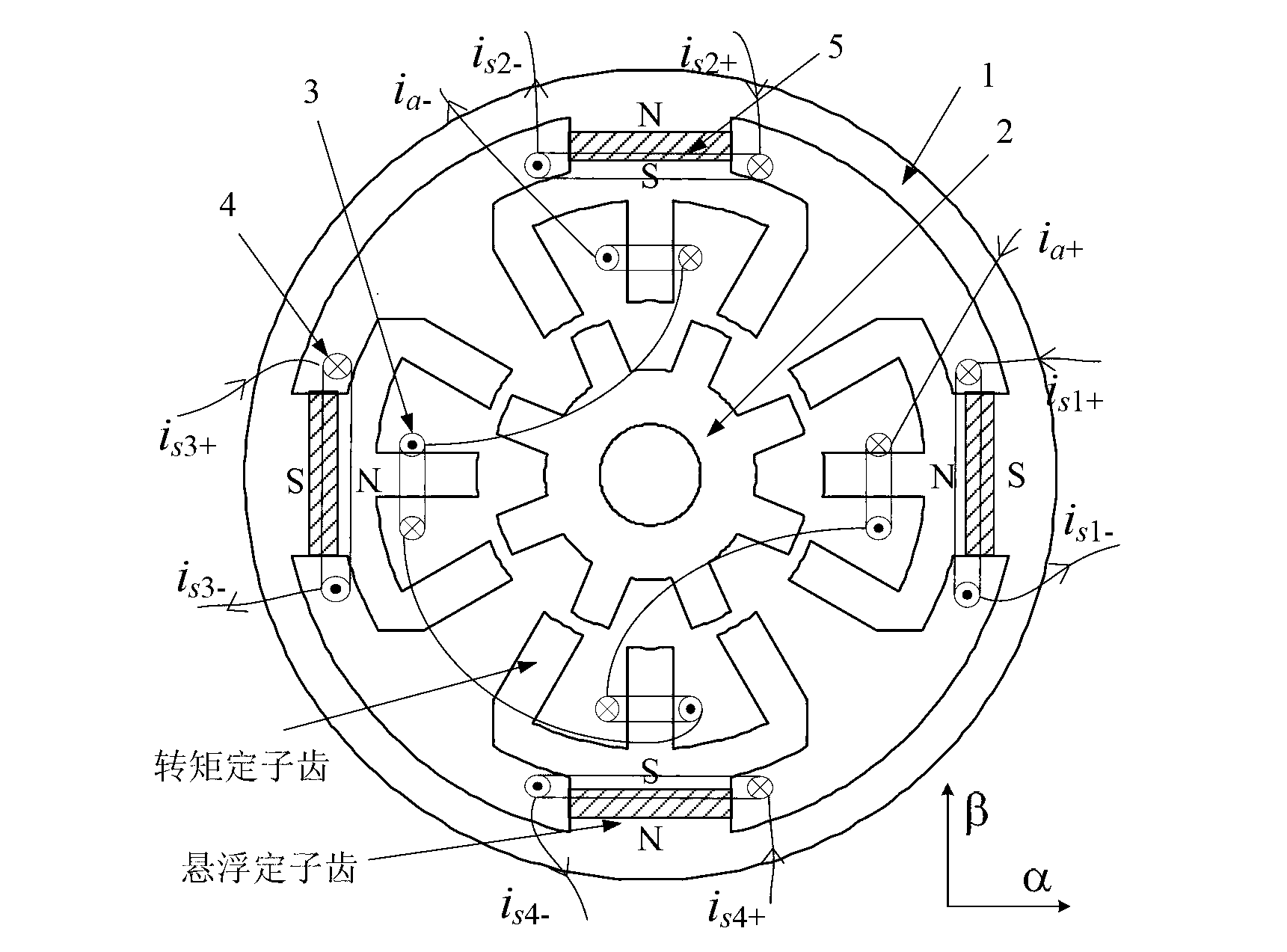

[0017] A bearingless switched reluctance motor proposed by the present invention will be further described below in conjunction with the accompanying drawings.

[0018] like figure 1 Shown is a schematic structural diagram of a bearingless switched reluctance motor embodiment 1 of the present invention, which is a three-phase 12 / 8-pole bearingless switched reluctance motor, wherein 1 is the stator yoke, 2 is the rotor, and 3 is the Torque winding, 4 is a suspension winding. The stator yoke protrudes 4 suspension stator teeth, and each suspension stator tooth respectively protrudes 3 torque stator teeth; each torque stator tooth is wound with a torque winding, and each suspension stator tooth is wound with a suspension stator tooth respectively. Windings; the torque windings on the 4 opposite teeth are connected in series to form a phase, and the 4 suspension windings form a single set of windings, and the current of each suspension winding is independently controlled. in i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com