Duck depilation process flow and production line thereof

A technological process and production line technology, which is applied in the field of duck depilation process and its production line, can solve problems such as the mouth being twisted, and achieve the effect of increasing economic value and reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

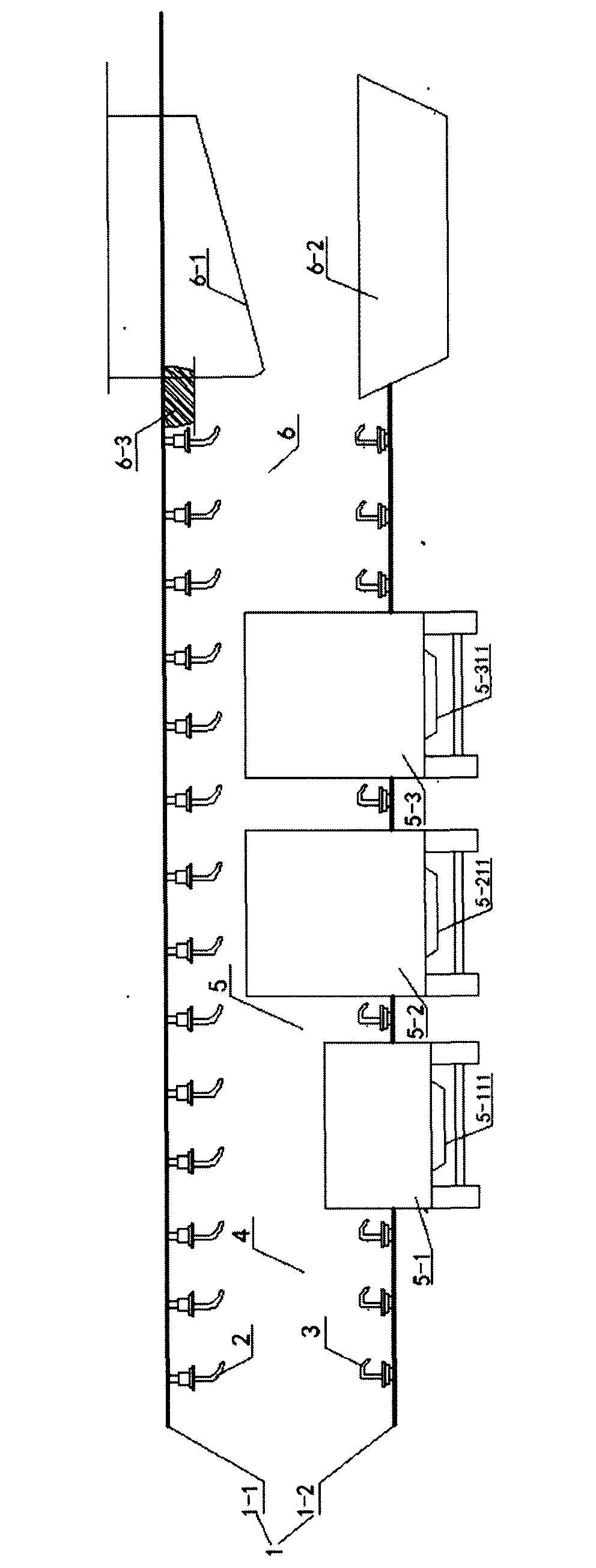

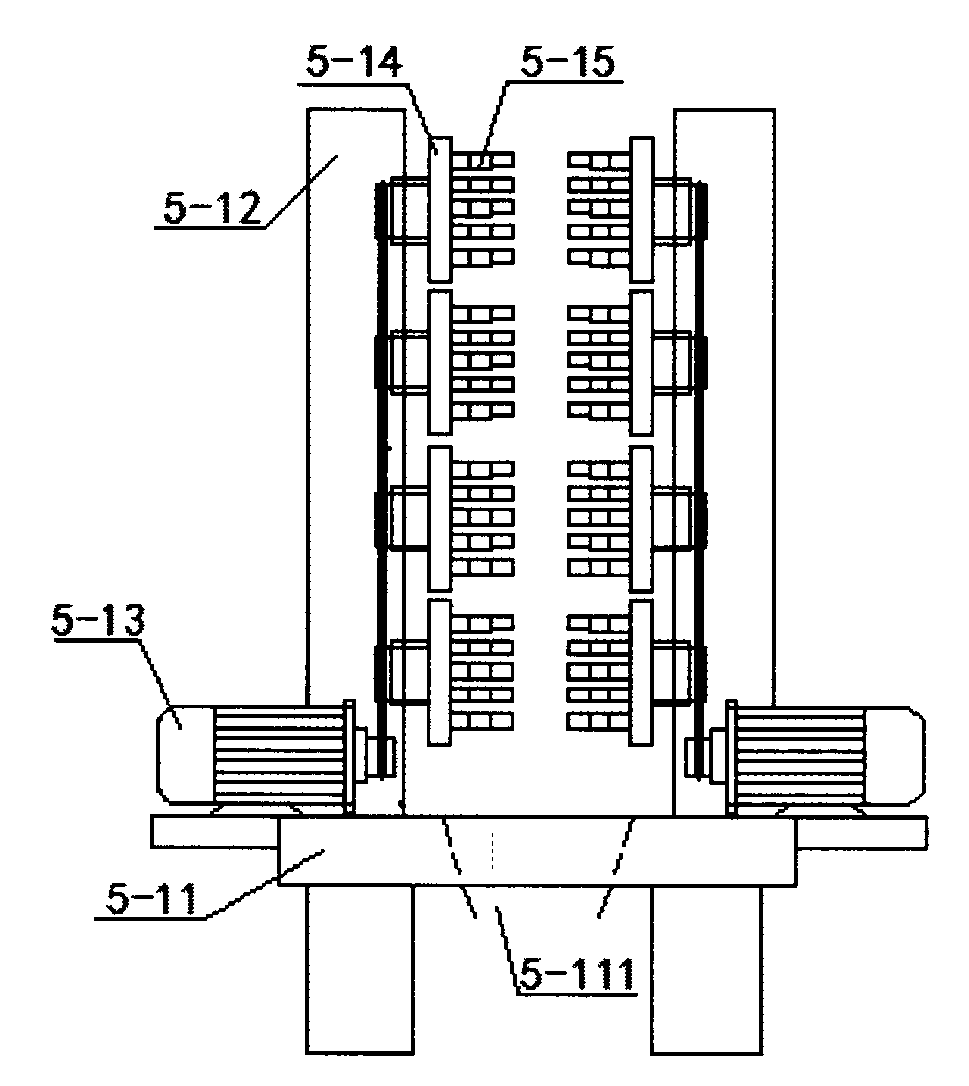

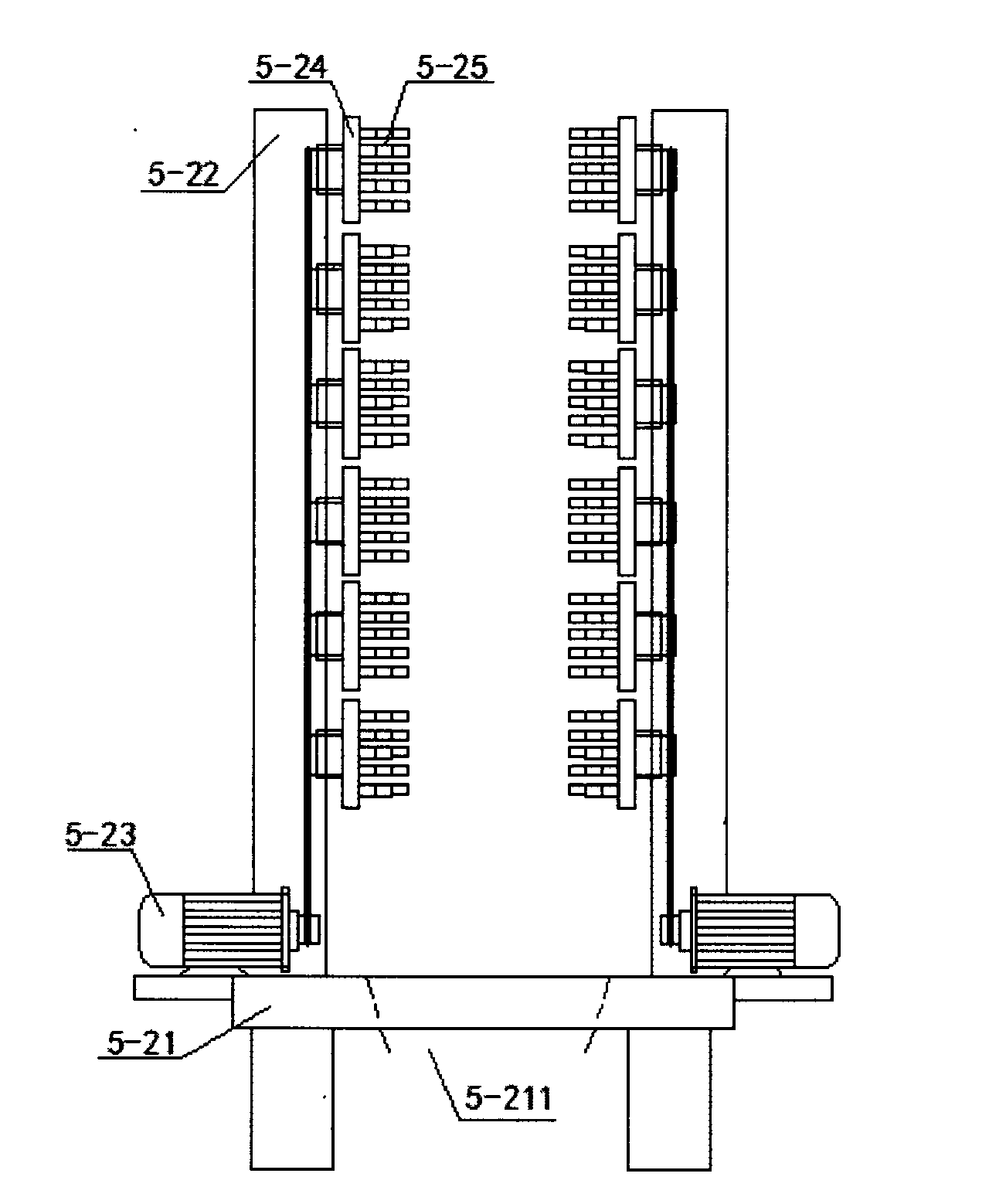

[0020] refer to figure 1 , a duck hair removal process and its production line, the production line includes a conveying and positioning device 1, the conveying and positioning device 1 includes two synchronous conveyor belts that are symmetrical up and down, and the upper conveyor belt 1-1 is provided with rotatable conveyor belts at a certain interval The hanger 2, the lower conveyor belt 1-2 is provided with the rotatable duck head fixing frame 3 corresponding to the rotatable hanger 2; along the conveying direction of the conveying positioning device 1, the hanging duck station 4, Depilation station 5, duck unloading station 6. Described depilatory station 5 is provided with such as in order figure 2 Shown neck hair removal device 5-1 and as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com