Split type orthopaedic soft drill and manufacturing method thereof

A production method and separate technology, applied in medical science, surgery and other directions, can solve the problems of product instability, easy fracture, complicated operation during operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

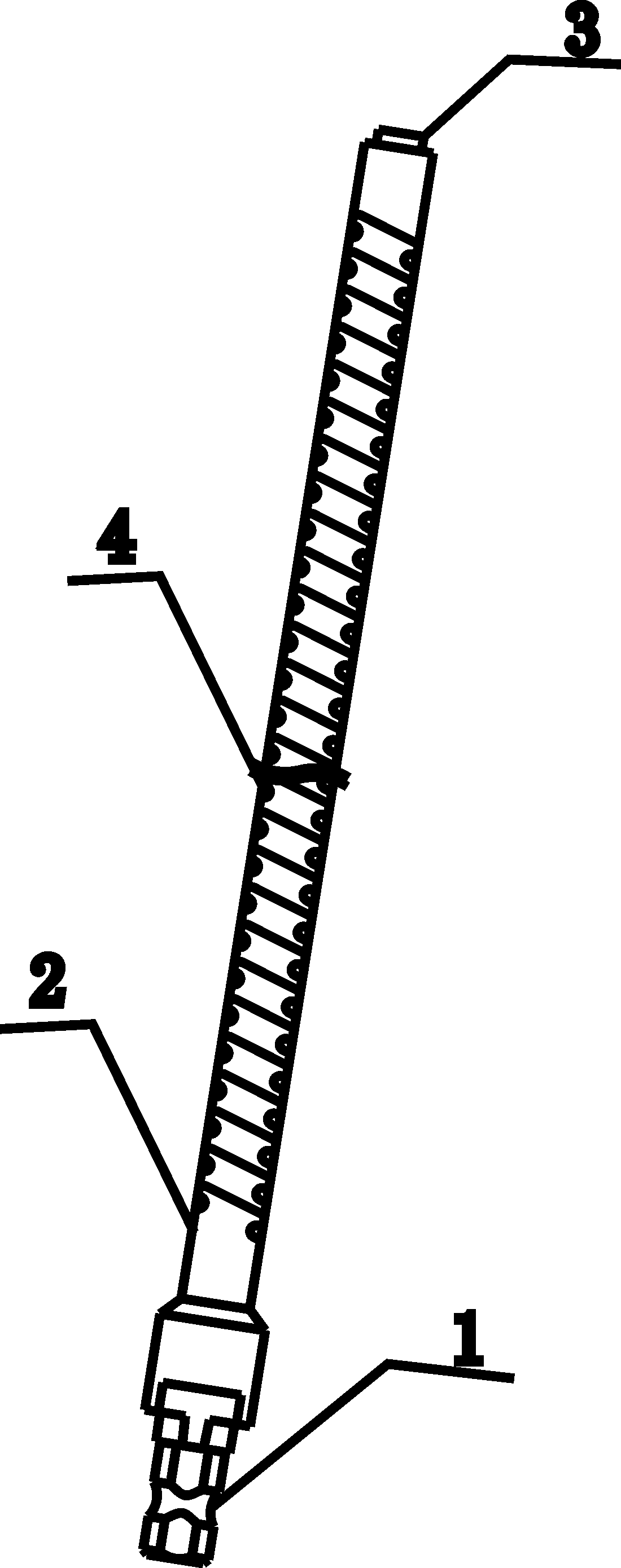

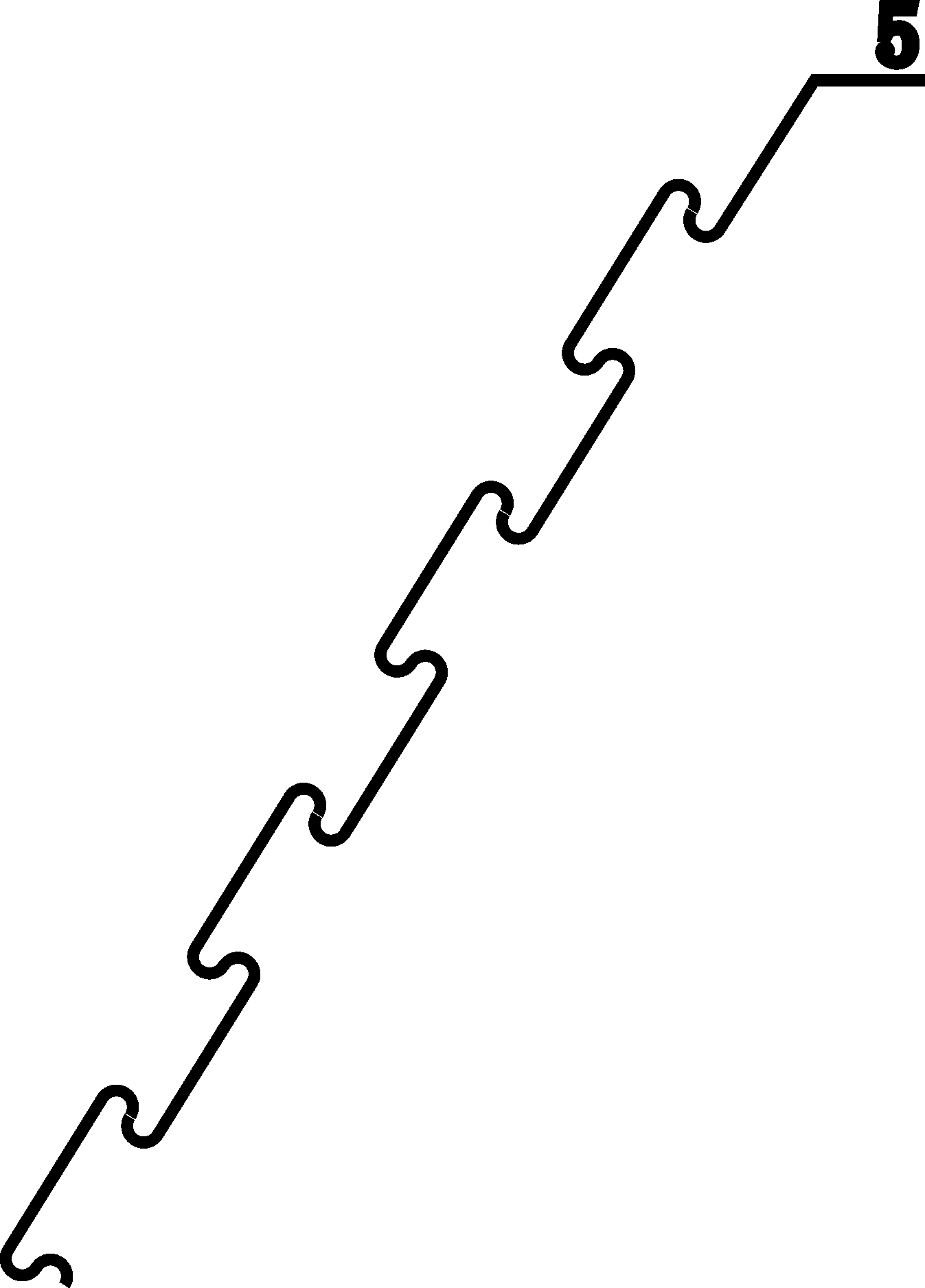

[0012] Such as figure 1 , figure 2 As shown, a split-type orthopedic soft drill includes: a drill handle 1, a flexible shaft 2, and a cutting edge joint 3 are integrated, and a groove 4 is also arranged on the flexible shaft 2, and it is characterized in that: the groove 4 spiral concave. The production method is as follows: firstly, a rigid hollow flexible shaft 2 is manufactured according to a conventional method, and the outer circle of the flexible shaft 2 is used as a reference to process it through a CNC engraving machine, and the concaves in each group of chain links on the cylindrical surface of the flexible shaft 2 are processed. Groove 4 is engraved along the track of its concave shoulder 5, forms upper and lower two groups of chain link helical connections, and so on gets final product. When a split-type orthopedic soft drill wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com