Gravity screening winze device and construction method thereof

A construction method and technology of slip shafts, applied in chemical instruments and methods, screening, solid separation, etc., can solve the problems of high mining costs, achieve the effects of reducing mining costs, avoiding the increase of mining costs, and improving ore grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

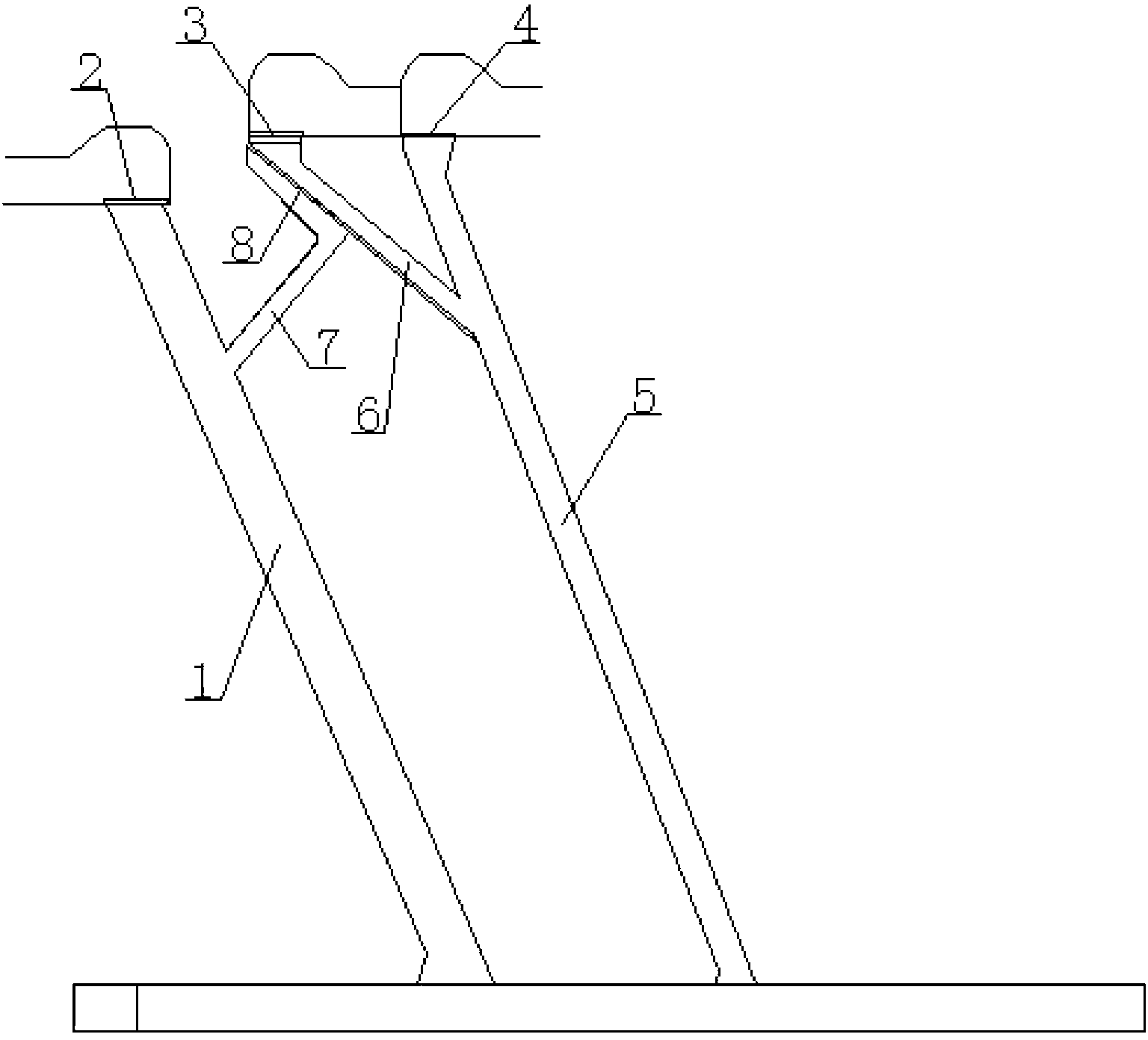

[0025] An embodiment of a gravity screening chute device, in figure 1 Among them, the left chute 1 and the right chute 5 are parallel to each other, and the angle between them and the horizontal plane is 60°, and the middle chute 6 is arranged between the left chute 1 and the right chute 5, and the three chutes are arranged side by side. The angle between the chute 6 and the horizontal plane is 40°, the middle chute 6 communicates with the right chute 5, and the middle chute 6 extends to the right chute without bending in the middle. The side wall of the middle chute 6 near the left chute 1 is provided with a chute 8, the chute 8 is grid-shaped and is composed of rail steels arranged in parallel, the distance between two adjacent rail steels is 12CM, and the extension of the rail steel The direction is the up-and-down direction of the middle chute, and a communication chute 7 is arranged between the middle chute 6 and the left chute 1, and the position where the communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com