Vertical machine tool with double workbenches

A technology of double worktables and worktables, applied in the directions of metal processing machinery parts, metal processing, manufacturing tools, etc., can solve the problems of low space utilization, consume a lot of time, reduce the production efficiency of machine tools, etc., to protect operations and increase processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

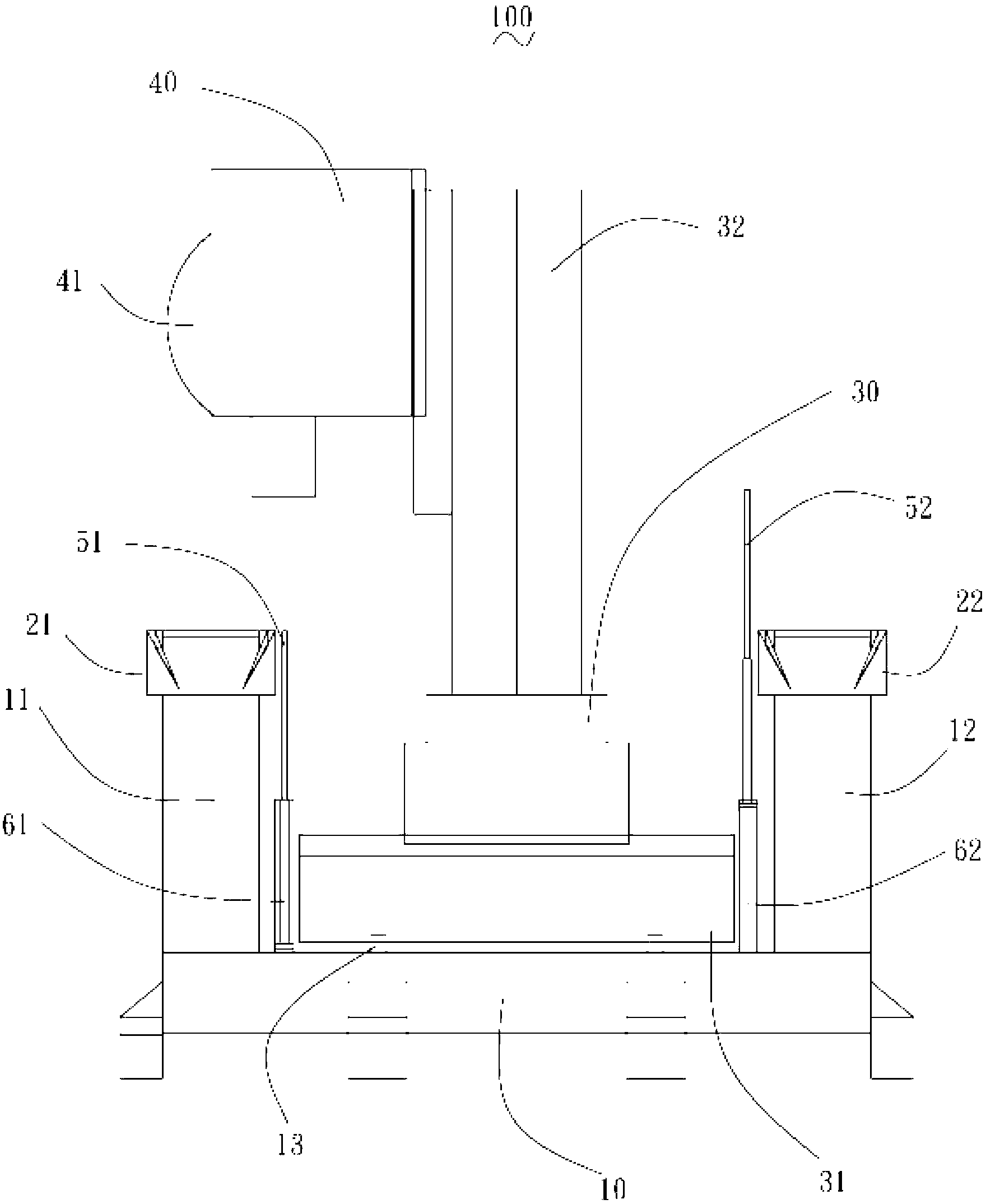

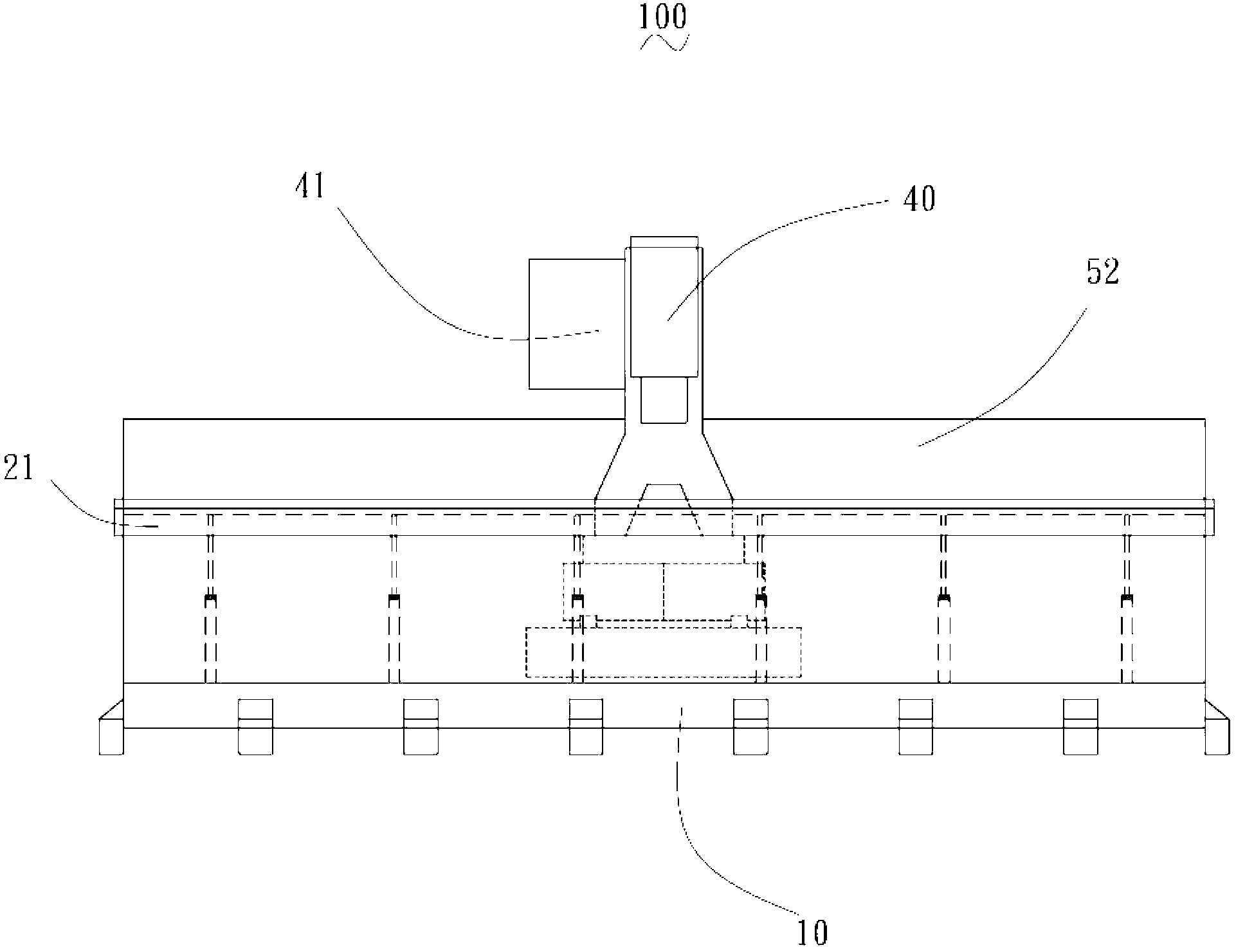

[0018] Such as figure 1 and figure 2 Shown is a double-table vertical machine tool 100 according to a preferred embodiment of the present invention. The double-table vertical machine tool 100 is a CNC machining center machine tool in this embodiment. The double-worktable vertical machine tool 100 includes a bed 10, a first workbench 21 and a second workbench 22 fixed on opposite sides of the bed 10, and is arranged between the first workbench 21 and the second workbench 22. Between the rotary table 30, and the headstock 40 provided on the rotary table 30. A first safety baffle 51 and a first air cylinder 61 connecting the bed 10 and the first safety baffle 51 are disposed between the first workbench 21 and the rotary table 30 . A second safety baffle 52 and a first air cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com