Bobbin shunt-wound machine

A separate winding and bobbin technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of low winding efficiency and uneven winding, so as to improve the winding efficiency and ensure the safety of the winding environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

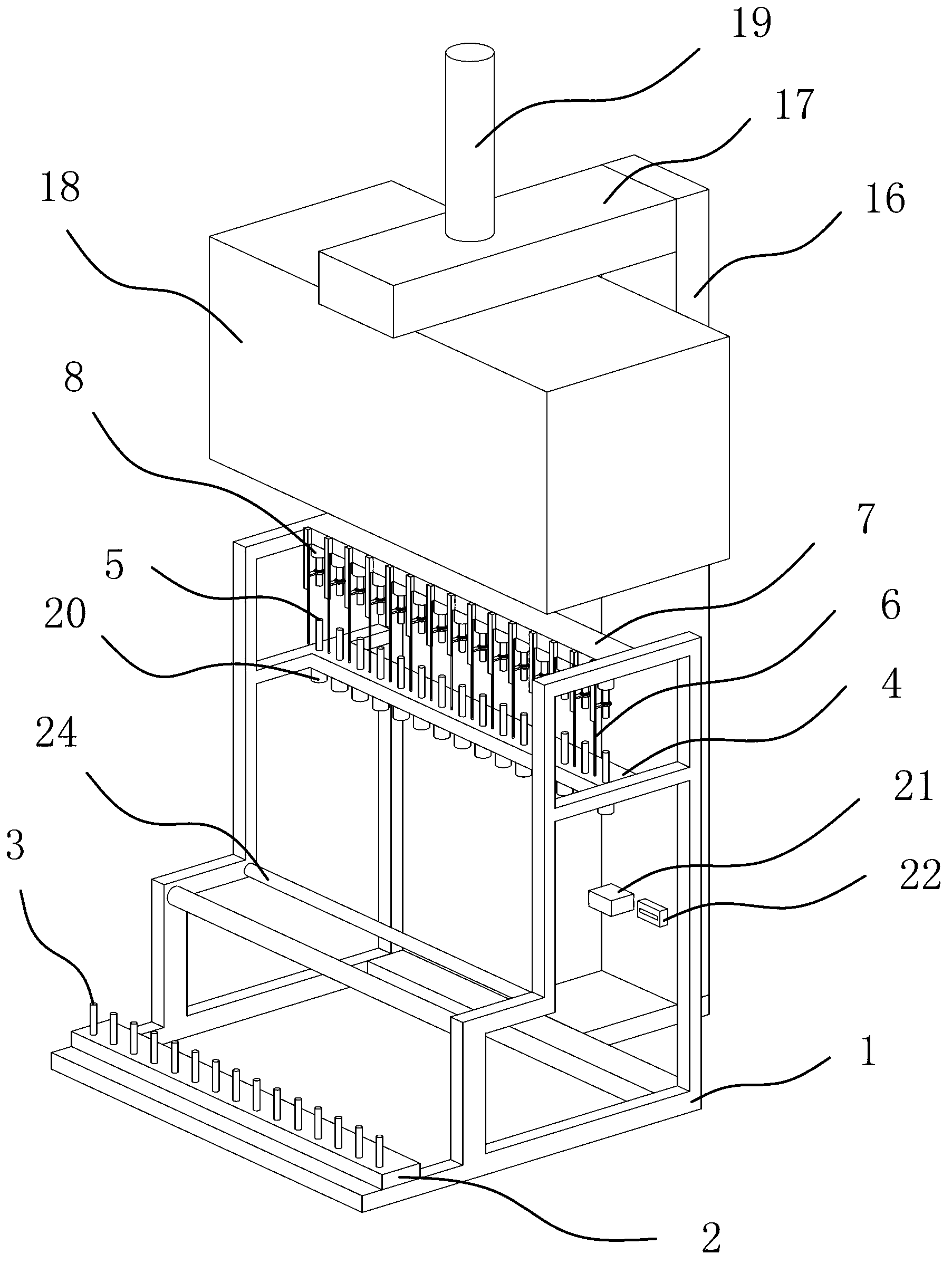

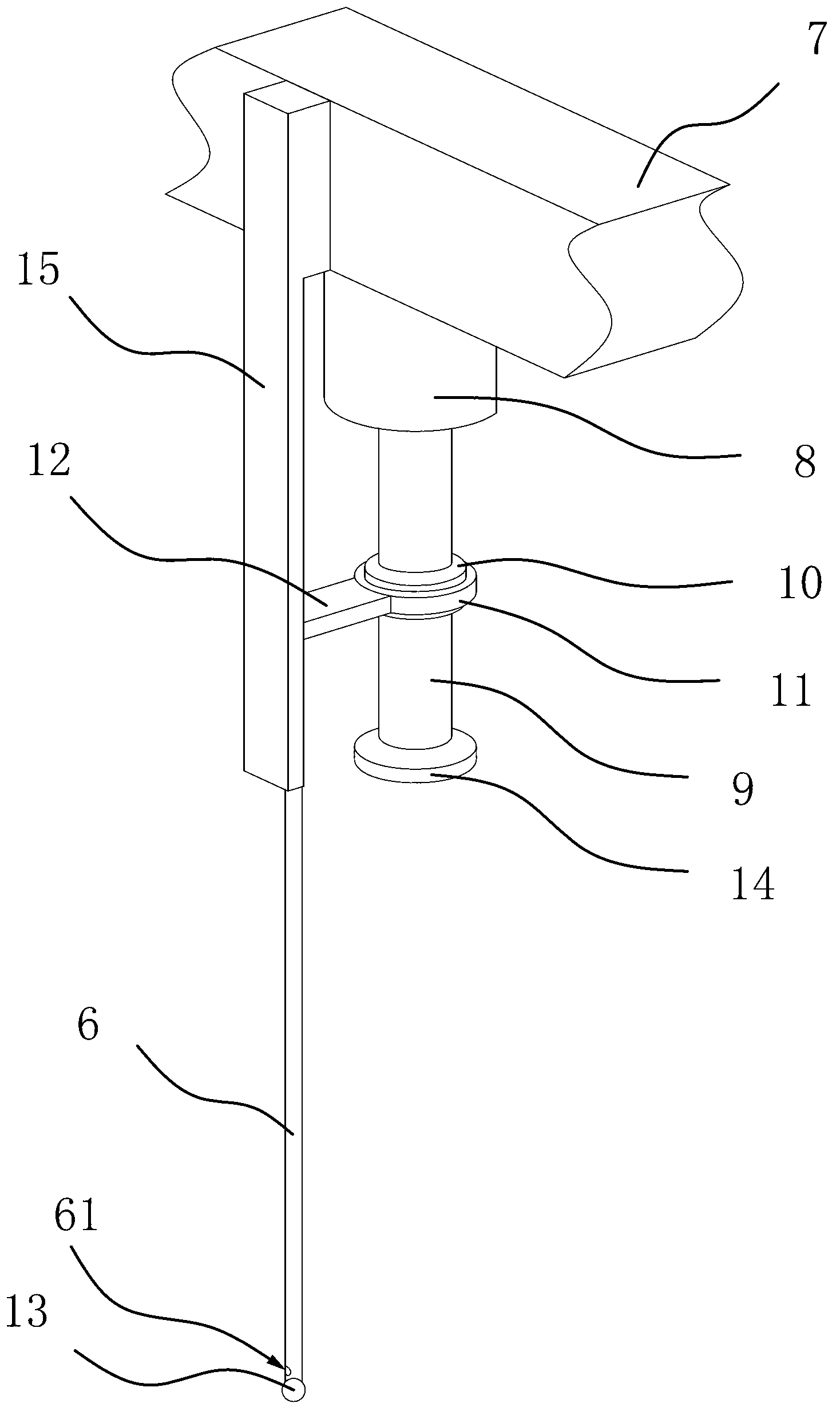

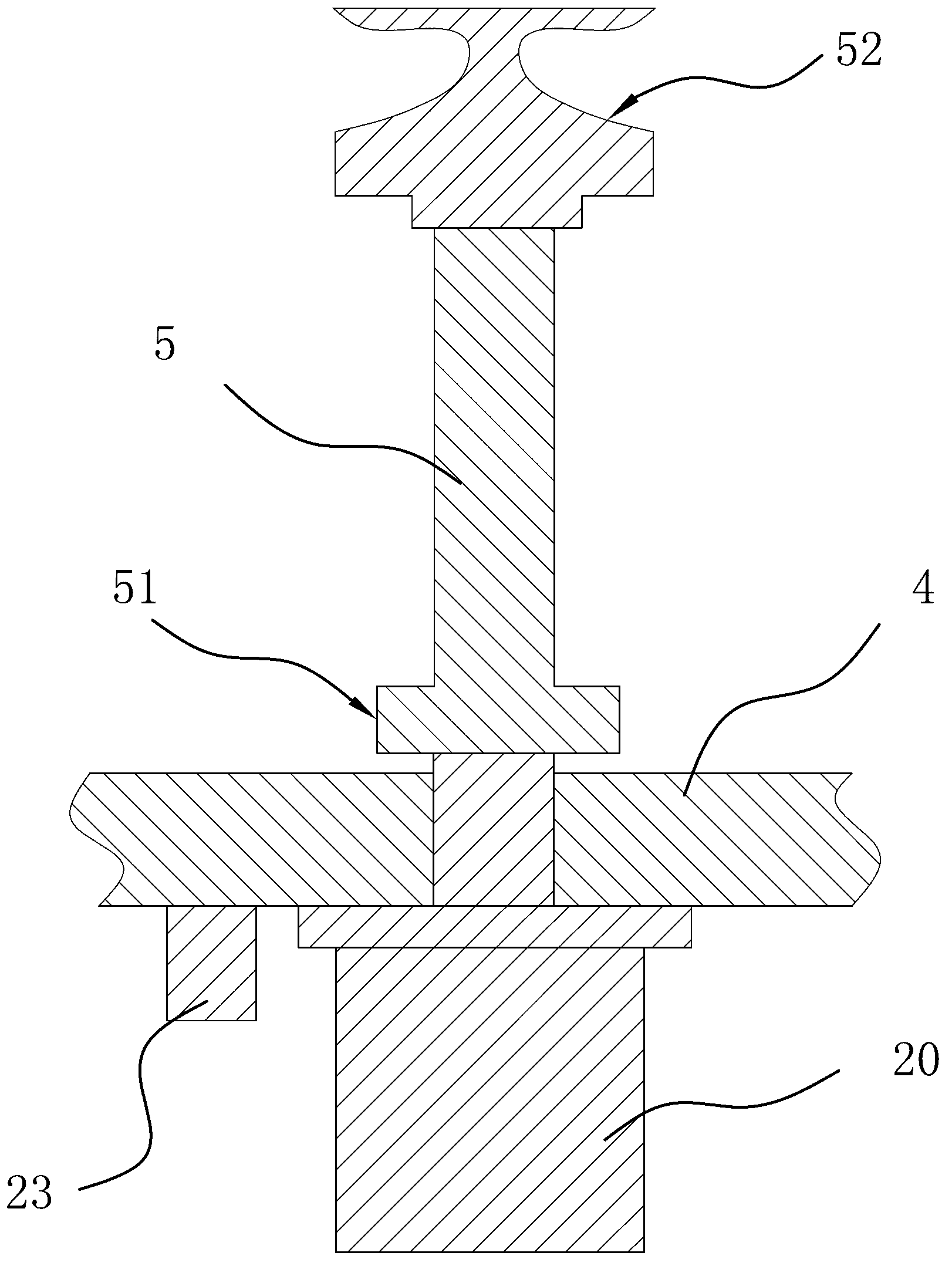

[0028] Such as figure 1 As shown, a bobbin winding machine includes a frame 1, on which a mounting plate 2 and a mounting plate 4 are fixed, and the mounting plate 2 4 is located obliquely above the mounting plate 2, and the mounting plate 2 There are a number of inserting rods 13 for placing the main line barrel fixed on the top, and a number of inserting rods 5 for placing the auxiliary line barrels are arranged on the mounting plate 24, and one end of the inserting rod 25 is provided with a drive inserter The driving mechanism for the rotation of the rod two 5, the other end of the insertion rod two 5 is the insertion end, between the insertion rod one 3 and the insertion rod two 5, there is a thread that can guide the yarn on the insertion rod one 3 into the insertion Lead rod 6 on the rod two 5, lead rod 6 is arranged in parallel with insertion rod two 5, and one end of lead rod 6 offers a through hole 61 that can pass through for yarn, and lead rod 6 is also provided wit...

Embodiment 2

[0035] The structure and principle of this embodiment are basically the same as the first embodiment, the difference is that in the second embodiment, the telescopic mechanism includes a cylinder one, and one end of the guide rod 6 is fixed on the piston rod of the cylinder one, and the mounting plate two 4 is fixed with a fixed plate directly above, and cylinder one is fixed on the fixed plate, and the piston rod of cylinder one is vertically downward. When the cylinder works, the cylinder will drive the piston rod back and forth to expand and contract, and at the same time it can also drive the guide rod 6 fixed on the piston rod to expand and contract back and forth, and the head of the guide rod 6 will go back and forth in the corresponding winding area on the secondary bobbin Move, so that the yarn is evenly wound on the secondary bobbin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com