Electric wrench rack with water discharging groove and applicable to hot-line work

A live work and drainage channel technology, applied in the directions of wrenches, hand-held tools, wrenches, etc., can solve the problems of unfavorable search and placement of other objects, dizziness of operators, affecting the efficiency of live work, etc. Simple structure and high loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

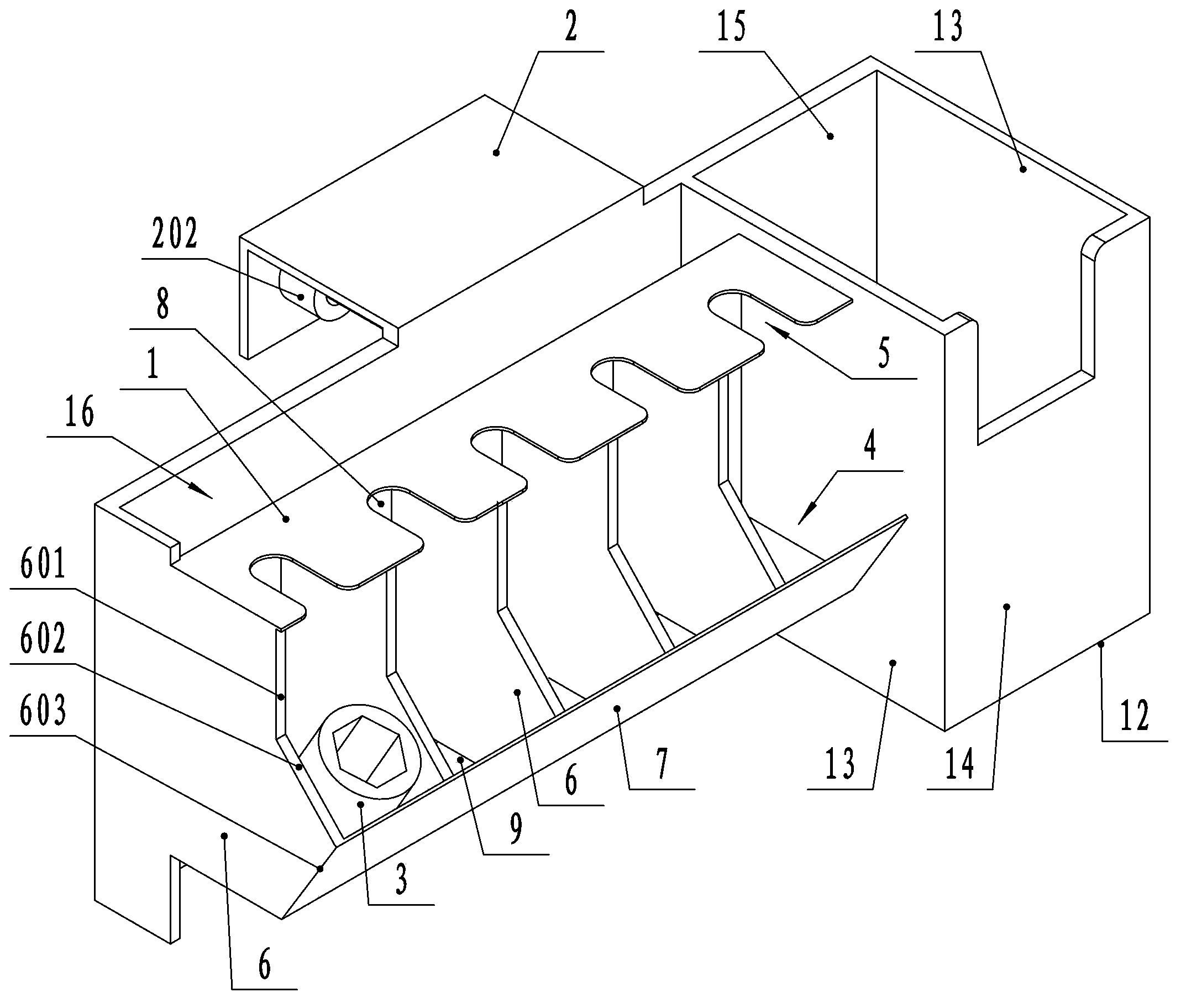

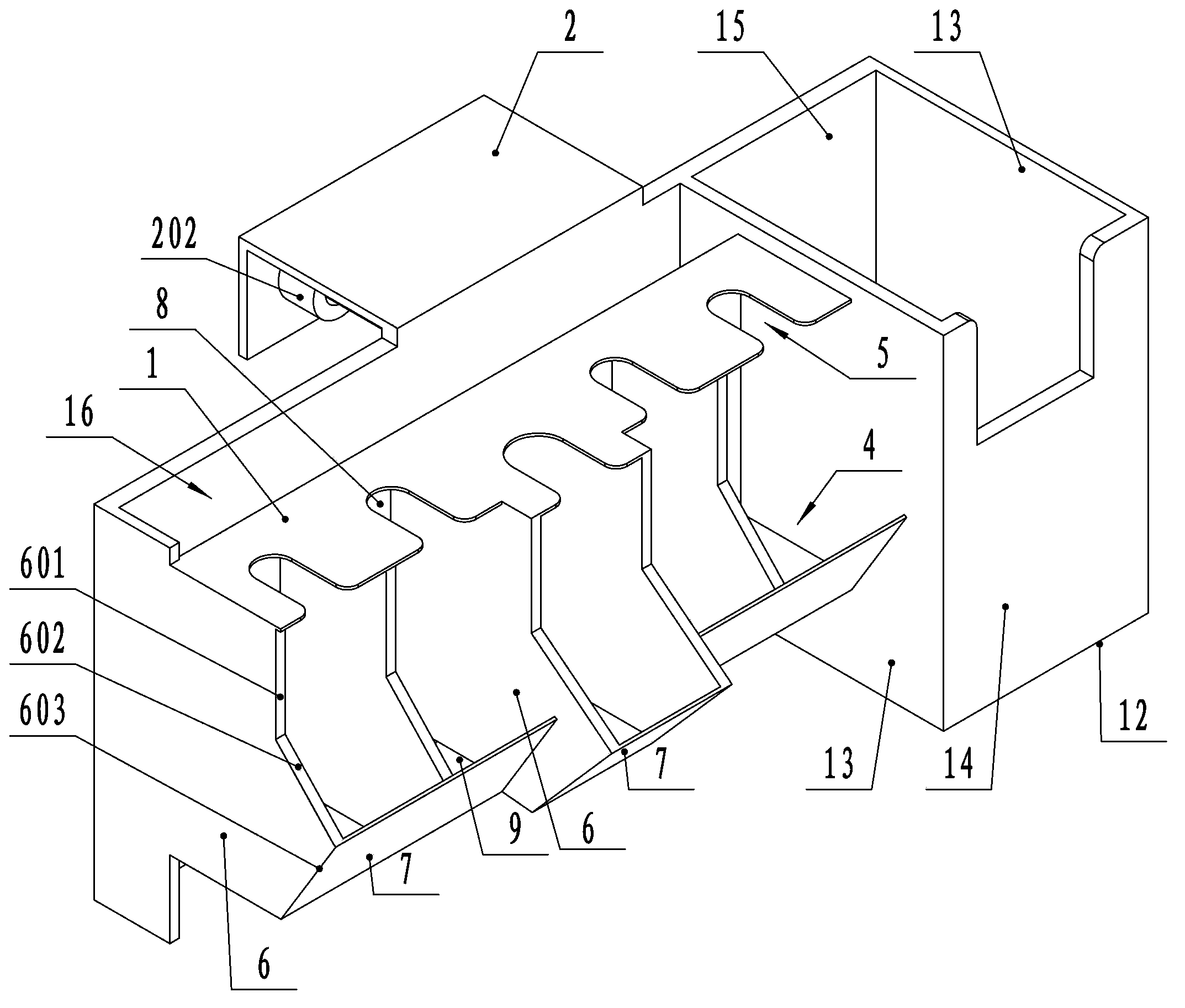

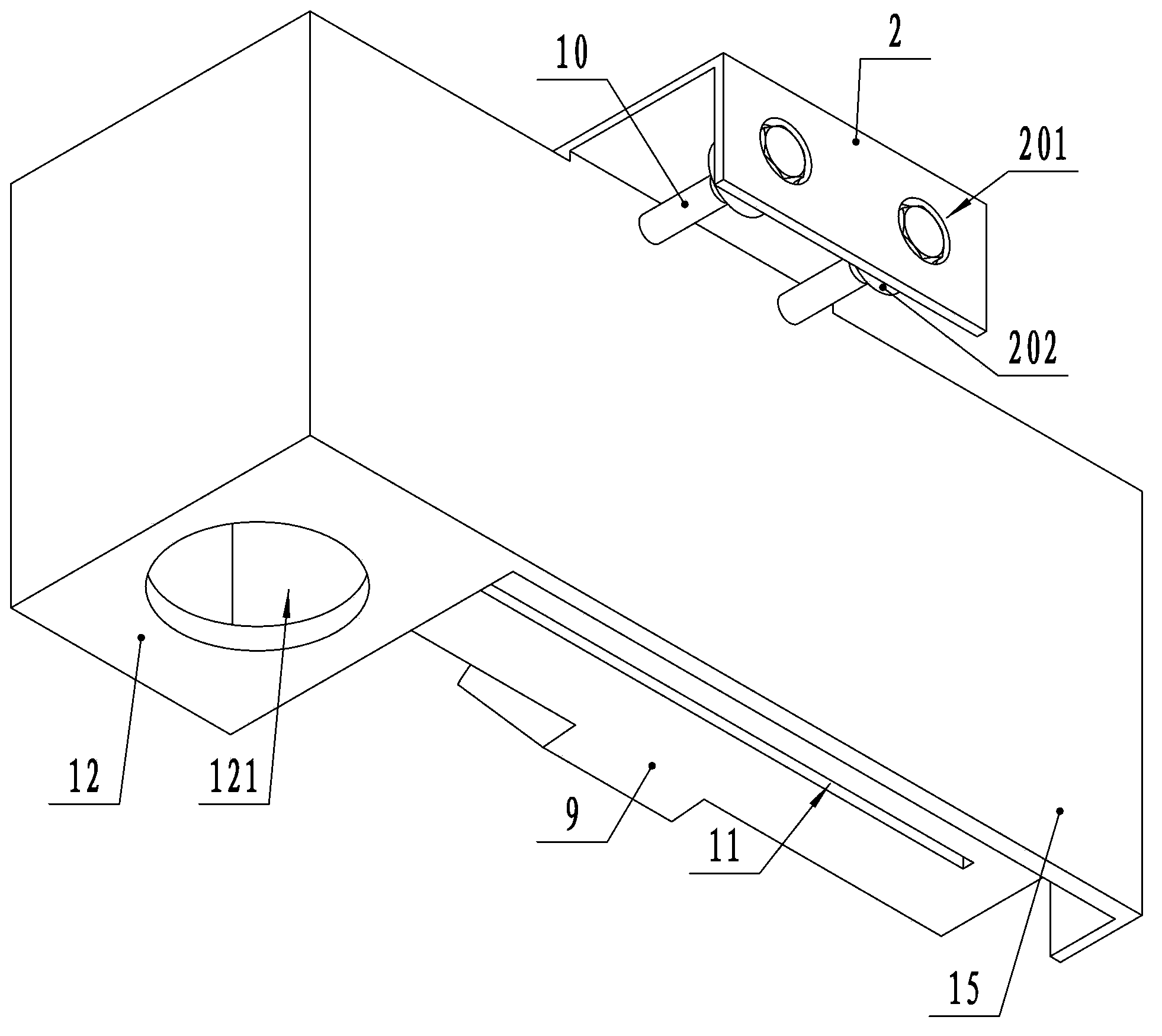

[0026] Such as figure 1 , 2 , 3, the present invention includes a sleeve 3 loader, a wrench placement frame located on one side of the sleeve 3 loader, a fixed frame 2 connecting the sleeve 3 loader and the wrench rack, and the sleeve 3 loader includes a transverse The installed unloading plate 1, the sleeve box located under the unloading plate 1, the rear plate 8 connecting the unloading plate 1 and the sleeve box, the unloading plate 1 has a plurality of "U" shaped slots 5 that can match the rotating shaft of the electric wrench , the opening of the slot 5 is chamfered or rounded, and the sleeve box is provided with a plurality of sleeve accommodation chambers 4 corresponding to the slot 5, the slot 5 communicates with the sleeve accommodation chamber 4, and the unloading plate 1 is connected to the sleeve There is a gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com