Multifunctional robot palletizer gripper

A palletizing robot and multi-functional technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of large footprint and high cost, and achieve the effects of strong applicability, light weight and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

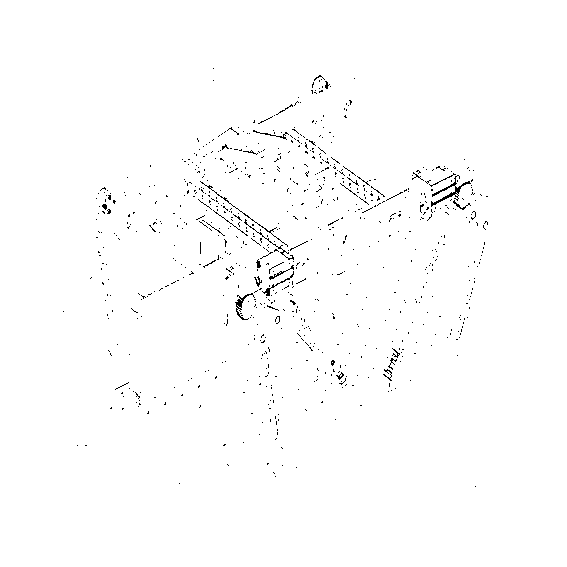

[0035] Figure 1 to Figure 9 A multifunctional palletizing robot gripper according to an embodiment of the present invention is schematically shown.

[0036] Such as figure 1 As shown, the gripper of the multifunctional palletizing robot of the present invention includes: a bracket 5, a horizontal clamping mechanism 1, a pallet clamping mechanism 2 and a cardboard suction mechanism 3, a horizontal clamping mechanism 1, a pallet clamping mechanism 2 and a cardboard suction mechanism The mechanisms 3 are all connected to the bracket 5 . The horizontal clamping mechanism 1 includes a lifting mechanism 11 .

[0037] Such as figure 1 As shown, the horizontal clamping mechanism 1 includes two clamping plates 101 arranged in parallel. The two clamping plates 101 are driven by the screw drive device 10 and the servo motor 4. The two clamping plates 101 move relative to each other, changing the distance between them. distance. The lifting mechanism 11 is connected to the two clamp...

Embodiment 2

[0060] The multifunctional palletizing robot gripper of the second embodiment of the present invention has basically the same structure as the structure in the embodiment, the difference is that:

[0061] In the horizontal clamping mechanism, the first clamping plate and the second clamping plate are slidably connected to the guide rail through the slider, and at the same time, the two clamping plates are respectively connected to the screw thread through two connecting blocks, and the thread directions of the two connecting blocks are opposite. The guide rail and the screw rod are perpendicular to the plane where the clamping plate is located.

[0062] Thus, bidirectional movement of the first clamping plate and the second clamping plate is realized.

[0063] Such as Figure 9 As mentioned above, the gripper of the multifunctional palletizing robot of the present invention is connected to the end of the arm of the robot 22 through the connecting arm 502 .

[0064] To sum up...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap