Integrated co-curing forming technology method for composite material multi-beam box section

A technology of composite materials and curing molding, which is applied in the field of overall co-curing molding technology of composite multi-beam box sections, can solve the problems of unguaranteed quality of the whole box section, difficulty in calculating the expansion amount, and unusability, etc., to achieve the benefit of heat Conduction and temperature uniformity, easy assurance of internal quality, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0045] According to a preferred embodiment of the present invention, the overall co-curing molding process method of composite multi-beam box segments includes the steps:

[0046] (1) Laying of beam slab: using automatic tape laying technology or manual paving technique, lay beam slab 1 on the beam slab tooling.

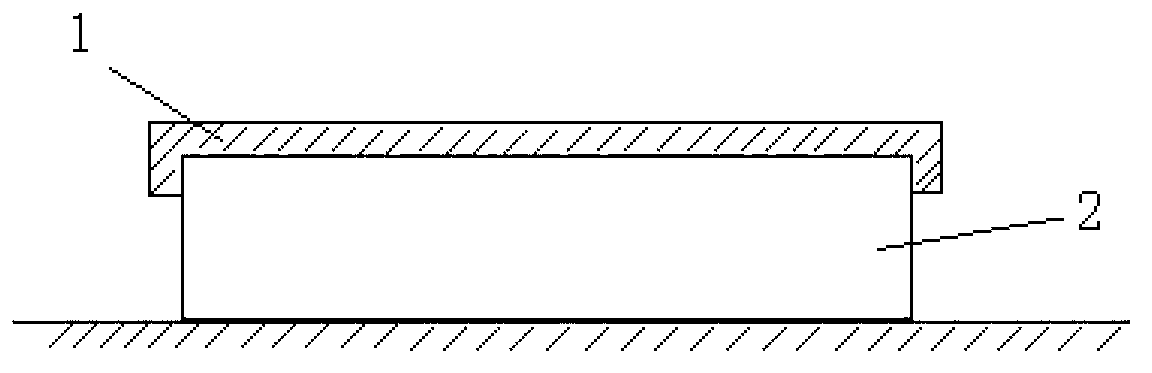

[0047] (2) Pre-forming of beam flat plate: such as figure 1 As shown in the figure, using hot diaphragm technology or manual bending technology, the beam plate 1 is preformed into a "C"-shaped beam in the beam preforming tool 2.

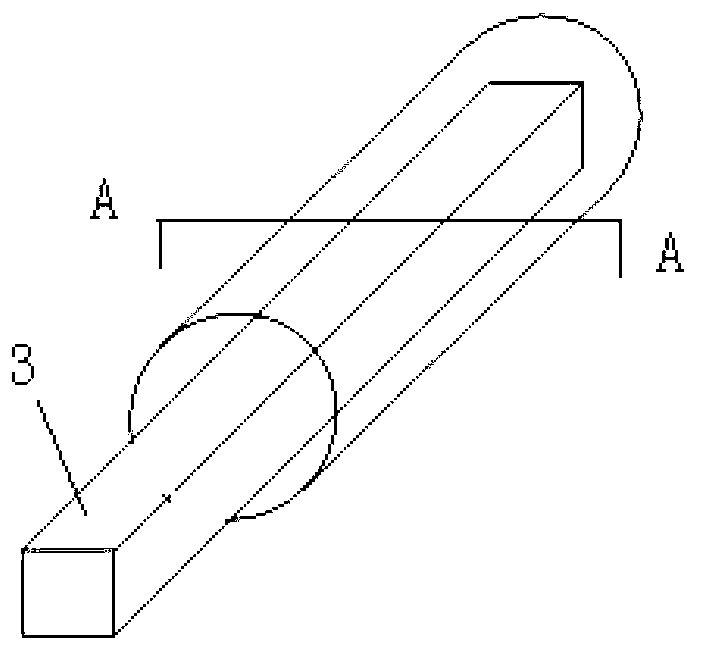

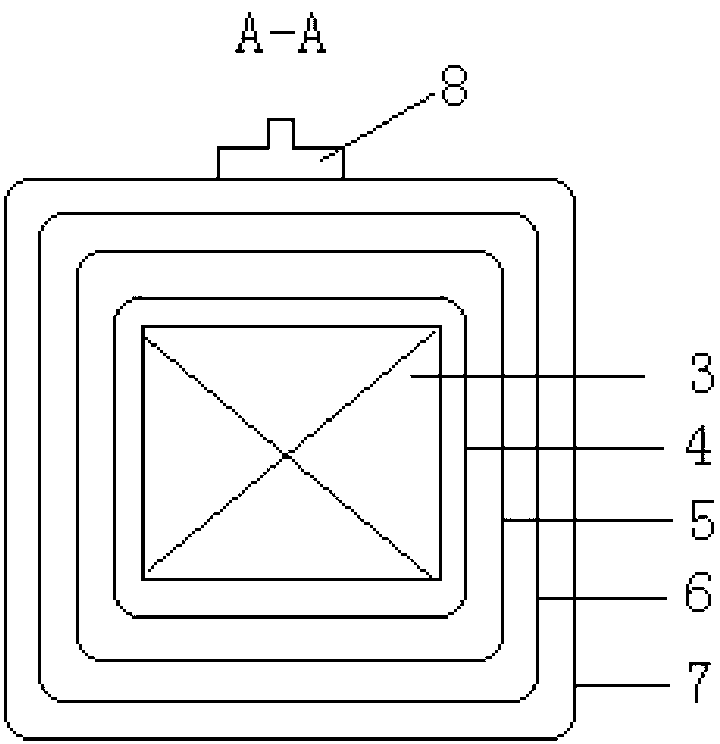

[0048] (3) Vacuum: such as Figure 2a-2b As shown in the figure, in order from the inside to the outside, the core mold 3, the isolation material 4, the tubular vacuum bag 5, the air felt 6, and the tubular non-porous isolation film 7 are pasted into the vacuum bag. A vacuum nozzle 8 is set on the outside of 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com