Preparation method for multi-color film

A kind of colorful and thin-film technology, applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of single response, single color change, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

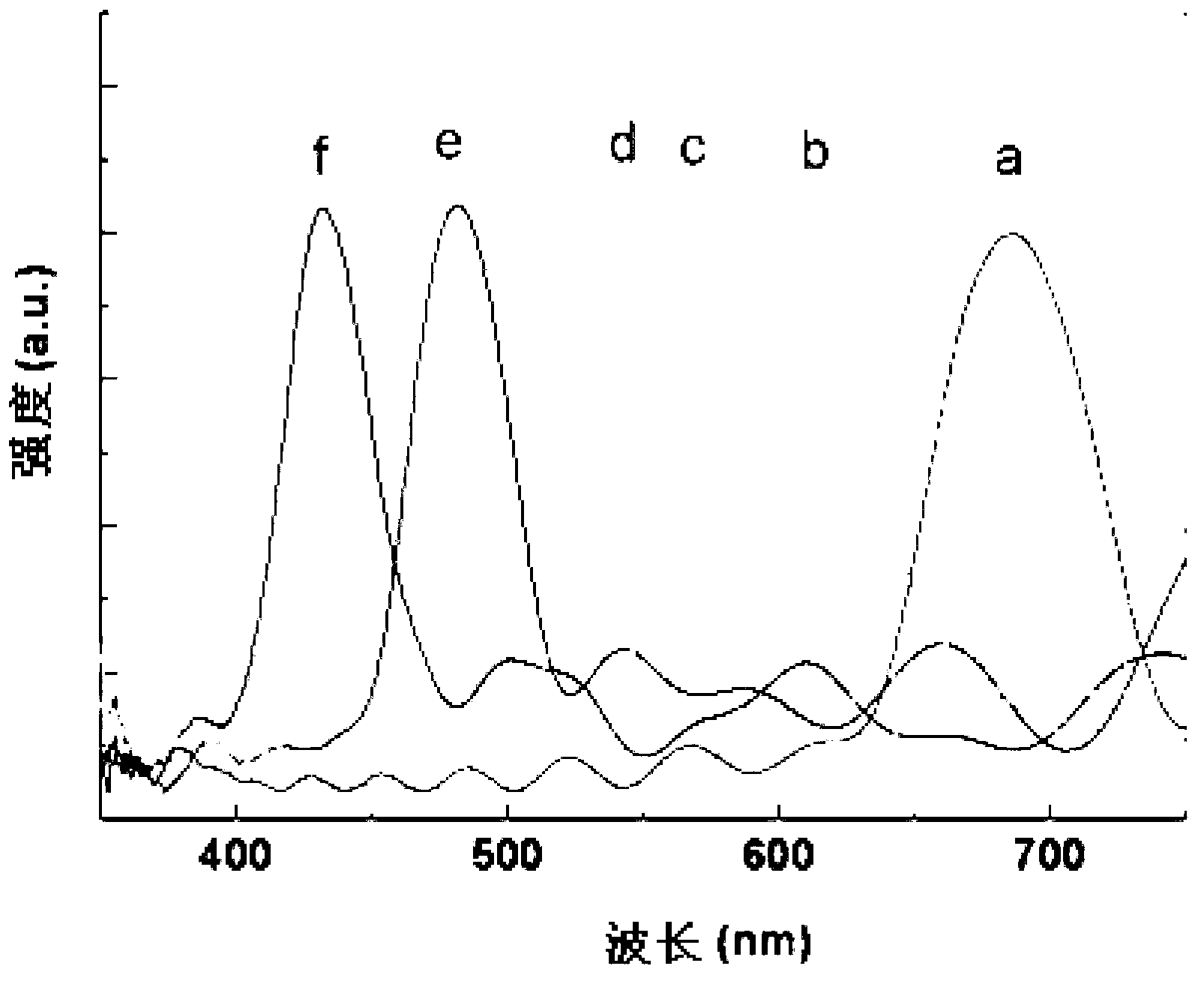

Image

Examples

specific Embodiment approach 1

[0017] Specific Embodiment 1: In this embodiment, a method for preparing a colorful thin film is specifically prepared according to the following steps:

[0018] 1. Mix L-arginine and deionized water, then put it in a water bath, stir L-arginine and deionized water evenly, then add cyclohexane to obtain a mixed solution; adjust the temperature of the water bath to 55°C-65°C ℃, control the stirring speed at 280rpm-320rpm, stir the mixed solution evenly, then keep the temperature of the water bath at 58℃-62℃, add ethyl orthosilicate, and stir for 18h-24h to obtain SiO 2 Seeds, wherein the mass ratio of L-arginine to deionized water is (12-14) mg: (9-11) mL, the volume of cyclohexane is 16 mL-20 mL, and the volume of tetraethyl orthosilicate 20mL ~ 24mL;

[0019] 2. Mix absolute ethanol and ammonia water with a mass concentration of 25% to 30%, then put it in a water bath with a temperature of 20°C to 30°C, and then add the SiO obtained in step 1 2 Seeds, control the stirring s...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 1, the stirring speed is controlled to 300 rpm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 in that the volume ratio of the mass of L-arginine to deionized water in step 1 is 13 mg:10 mL. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com