Dual-purpose grease composition for rust protection and lubrication, and production method thereof

A technology of anti-rust lubrication and composition, which is applied in the direction of lubricating composition and petroleum industry, which can solve the problems of inconvenient use and poor versatility of grease, and achieve the effects of avoiding grease replacement work, improving performance, and excellent low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

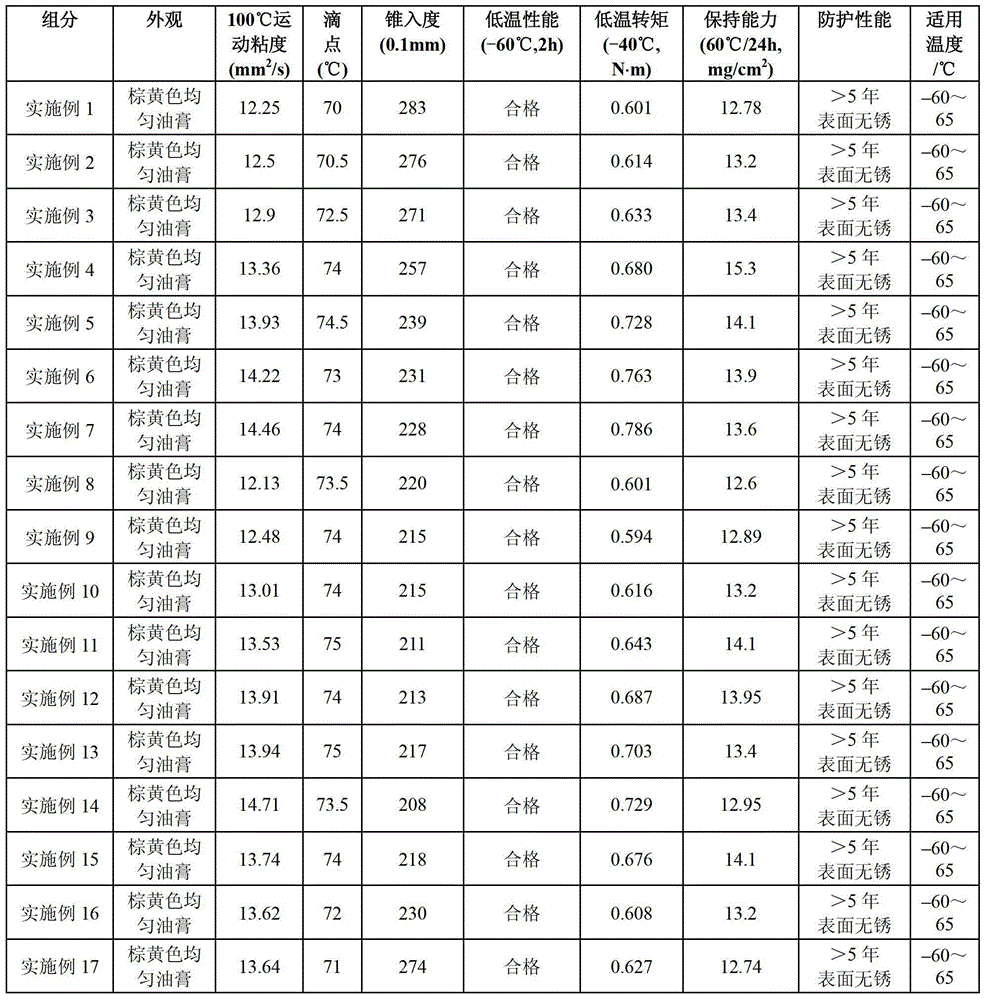

Examples

Embodiment 1

[0041] Add 0.2 g of 2,6-di-tert-butyl-p-cresol and 0.5 g of dibutyl phthalate into the kettle, heat to 60°C and stir at a constant temperature until they are completely dissolved to obtain a mixture A; α olefin synthetic oil (kinematic viscosity 8.39mm at 100°C 2 / s) 64.5g, stirred at 60°C for 20mim to obtain mixture B; then added low molecular weight polyisobutylene (100°C kinematic viscosity 630mm 2 / s) 5g and microcrystalline wax (dropping point 74°C, 100°C kinematic viscosity 17.65mm 2 / s) 30g into the mixture B in the reaction kettle, heated to 90°C, gradually stirred to raise the temperature to 120°C, then stirred at constant temperature for 30min, stirred evenly, and the finished product was obtained from the kettle.

Embodiment 2

[0043] Add 0.3 g of 2,6-di-tert-butyl-p-cresol and 0.7 g of dibutyl phthalate into the kettle, heat to 70°C and stir at a constant temperature until they are completely dissolved to obtain a mixture A; α olefin synthetic oil (kinematic viscosity 8.39mm at 100°C 2 / s) 62.3g, stirred at 70°C for 15mim to obtain mixture B; then added low molecular weight polyisobutylene (100°C kinematic viscosity 630mm 2 / s) 5g and microcrystalline wax (dropping point 74°C, 100°C kinematic viscosity 17.65mm 2 / s) 32g into the mixture B in the reaction kettle, heated to 90°C, gradually stirred to raise the temperature to 120°C, then stirred at constant temperature for 30min, stirred evenly, and the finished product was obtained from the kettle.

Embodiment 3

[0045] Add 0.5 g of 2,6-di-tert-butyl-p-cresol and 1.0 g of dibutyl phthalate into the kettle, heat to 70°C and stir at a constant temperature until they are completely dissolved to obtain a mixture A; α olefin synthetic oil (kinematic viscosity 8.39mm at 100°C 2 / s) 59g, stirred at 70°C for 15mim to obtain mixture B; then added low molecular weight polyisobutylene (100°C kinematic viscosity 630mm 2 / s) 5g and microcrystalline wax (dropping point 74°C, 100°C kinematic viscosity 17.65mm 2 / s) 35g into the mixture B in the reaction kettle, heated to 90°C, gradually stirred and heated to 125°C, stirred at a constant temperature for 20min, stirred evenly, and the finished product was obtained from the kettle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com