Preparing process of silicon carbide whisker toughened zirconium diboride ceramic

A silicon carbide whisker and zirconium diboride technology, which is applied in the field of inorganic composite material preparation, can solve the problems of uneven dispersion, damage, weakening of SiCw toughening effect, etc., achieve good bonding, avoid pollution, and solve the problem of dispersion uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

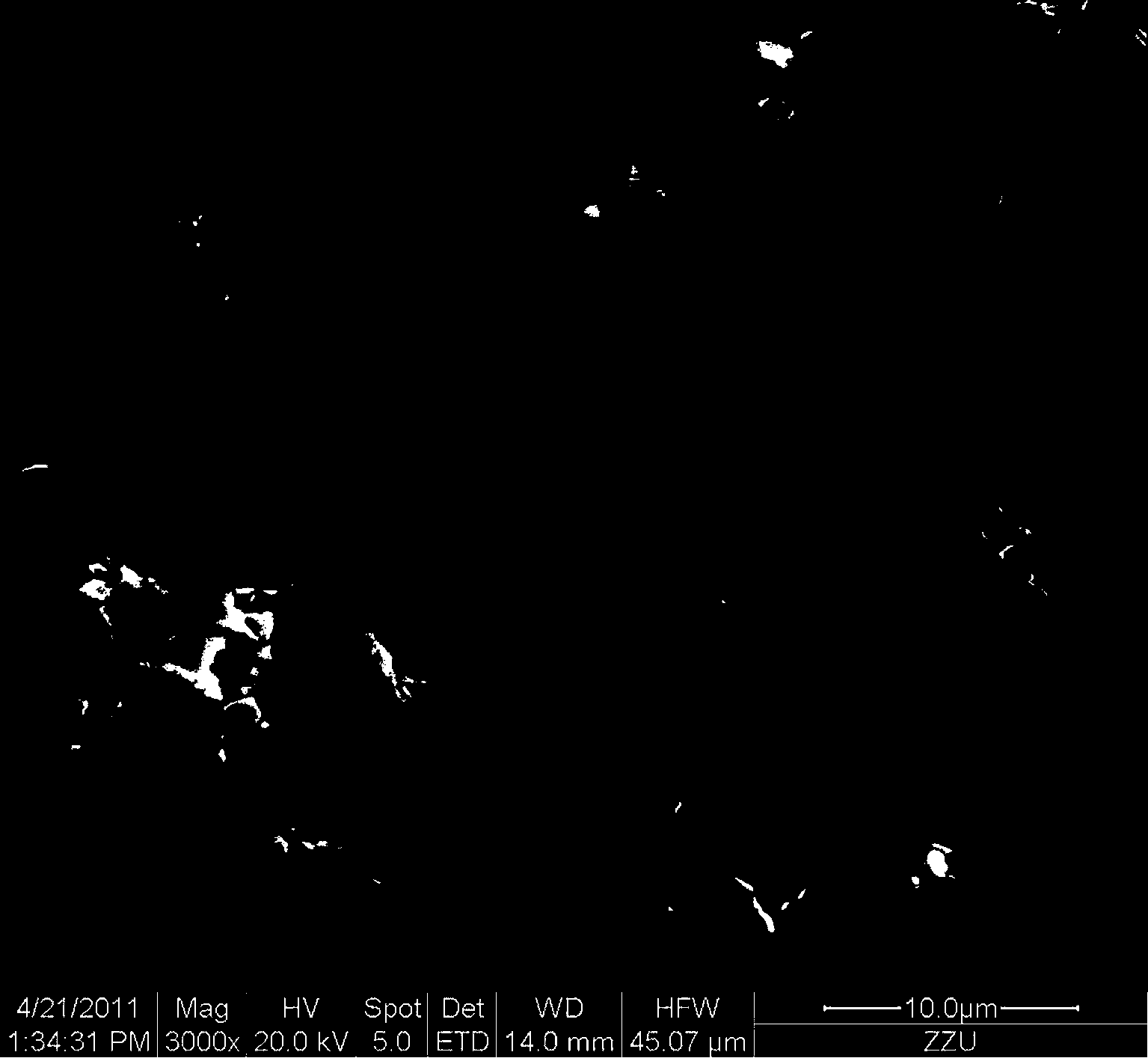

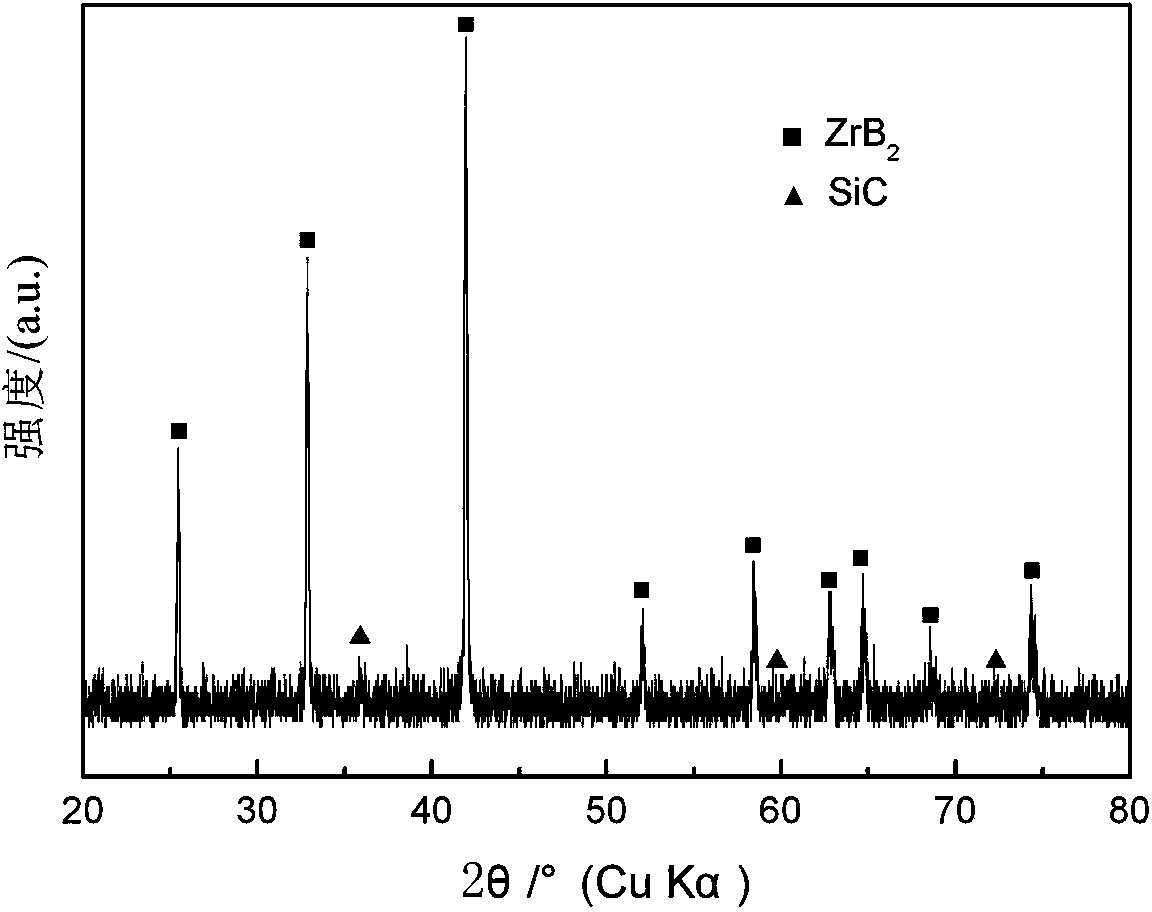

[0031] Measure 29ml of tetraethyl orthosilicate, 46ml of absolute ethanol, and 4ml of distilled water, pour them into a large beaker, add dilute hydrochloric acid dropwise while stirring, adjust the pH value to 3-4, let stand for 17 hours to fully hydrolyze the tetraethyl orthosilicate , followed by the addition of 87.7 g ZrB 2 , vigorously stirred for 1 h, then added sodium hydroxide solution to adjust the pH to 8-9, and allowed to stand for 5-10 min to form a gel. Dry it in an oven at 80°C, dry it for 24 hours, and grind it into powder. Then take activated carbon 4.56g and carry out thorough mixing with above-mentioned powder body. Put the mixed powder obtained above into a graphite crucible and put it into a vacuum tube atmosphere furnace, raise the temperature to 1500°C at 10°C / min, keep it warm for 2.5h, and use flowing argon as a protective atmosphere to naturally cool to obtain ZrB 2 -SiC w Composite powder. figure 1 is ZrB 2 -SiC w The SEM photo of the composite ...

Embodiment 2

[0035] Measure 58ml of tetraethyl orthosilicate, 93ml of absolute ethanol, and 8ml of distilled water, pour them into a large beaker, add dilute hydrochloric acid dropwise while stirring, adjust the pH value to 3-4, let stand for 17 hours to fully hydrolyze the tetraethyl orthosilicate , followed by the addition of 77.95 g ZrB 2 , vigorously stirred for 1 h, then added sodium hydroxide solution to adjust the pH to 8-9, and allowed to stand for 5-10 min to form a gel. Dry it in an oven at 80°C, dry it for 24 hours, and grind it into powder. Then take 9.13g of activated carbon and fully mix with the above-mentioned powder. Put the mixed powder obtained above into a graphite crucible and put it into a vacuum tube atmosphere furnace, raise the temperature to 1500°C at 10°C / min, keep it warm for 2.5h, and use flowing argon as a protective atmosphere to naturally cool to obtain ZrB 2 -SiC w Composite powder.

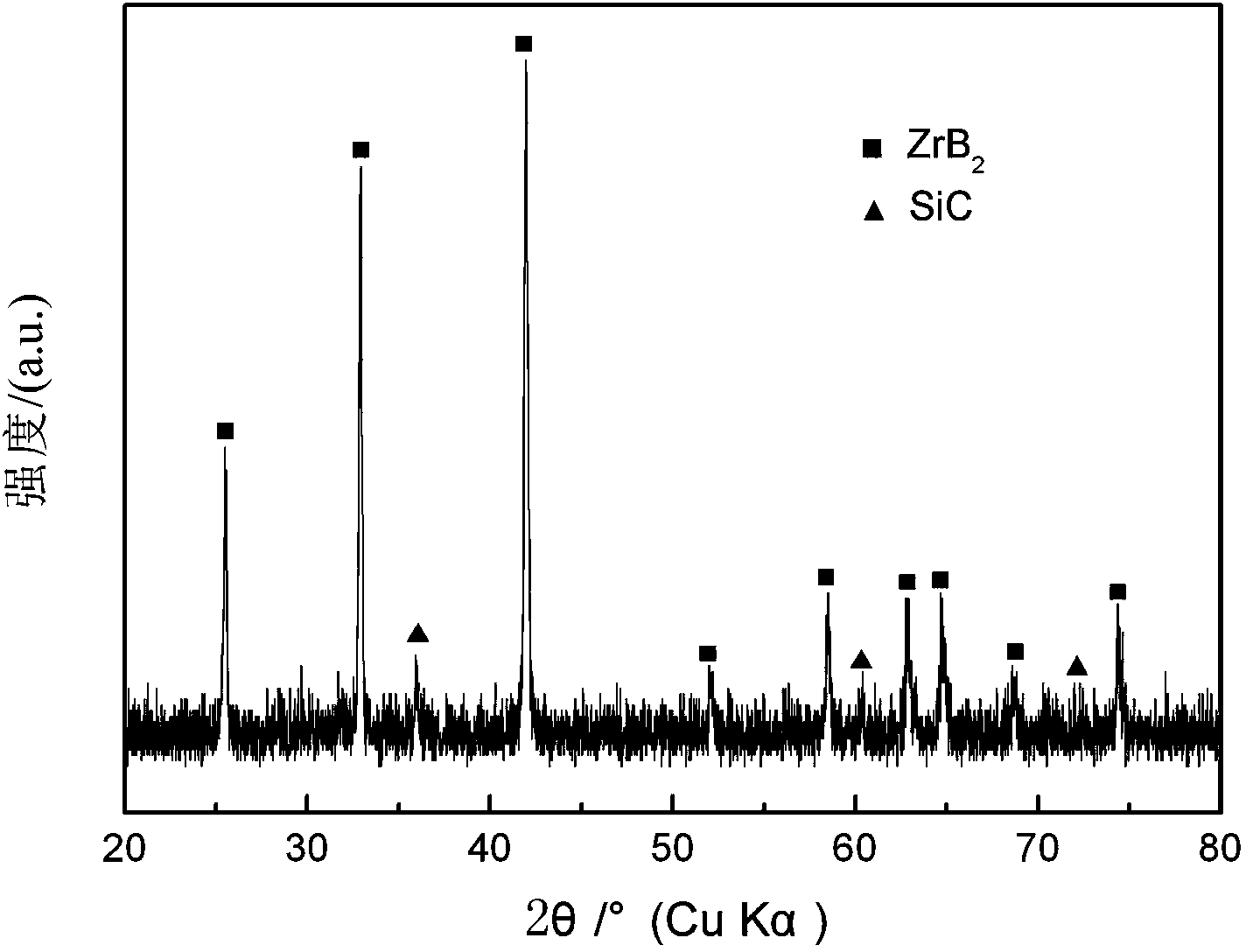

[0036] Weigh 25g of the above-mentioned treated ZrB 2 -SiC w Put th...

Embodiment 3

[0039] Measure 93ml of tetraethyl orthosilicate, 148ml of absolute ethanol, and 13ml of distilled water, pour them into a large beaker, add dilute hydrochloric acid dropwise while stirring, adjust the pH value to 3-4, and let it stand for 17 hours to fully hydrolyze the tetraethyl orthosilicate , followed by the addition of 72.47 g ZrB 2 , vigorously stirred for 1 h, then added sodium hydroxide solution to adjust the pH to 8-9, and allowed to stand for 5-10 min to form a gel. Dry it in an oven at 80°C, dry it for 24 hours, and grind it into powder. Then take active carbon 14.55g and carry out thorough mixing with above-mentioned powder body. Put the mixed powder obtained above into a graphite crucible and put it into a vacuum tube atmosphere furnace, raise the temperature to 1500°C at 10°C / min, keep it warm for 2.5h, and use flowing argon as a protective atmosphere to naturally cool to obtain ZrB 2 -SiC w Composite powder.

[0040] Weigh 25g of the above-mentioned treated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com