High salt mist resistant industrial gear oil

An industrial gear oil and salt spray technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of exceeding the operating life and early failure, and achieve the effects of prolonging the service life, prolonging the oil change period, and outstanding corrosion protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

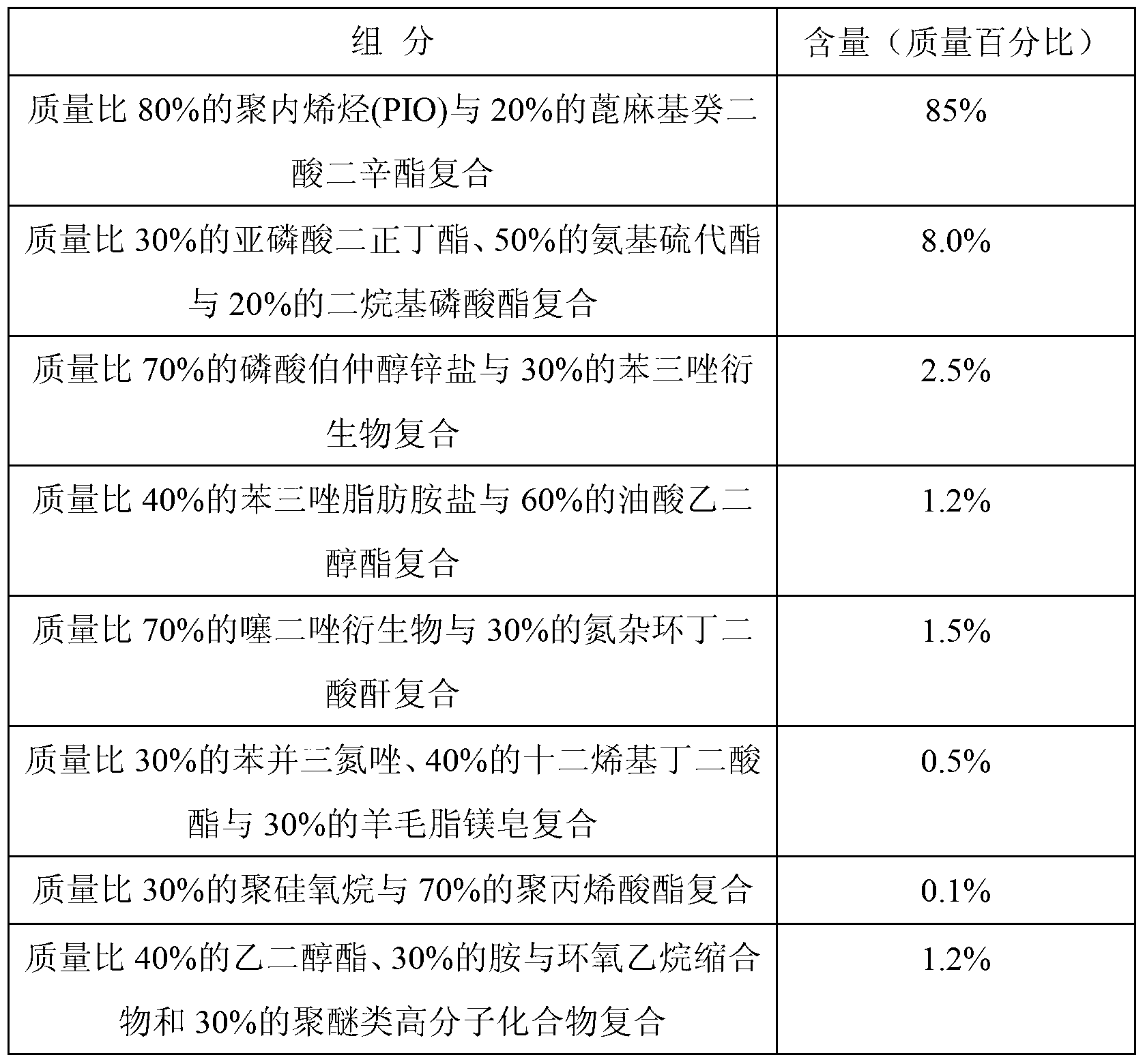

Embodiment 1

[0021] Blend the following components in mass percentage:

[0022]

[0023] The sum of the above components is 100%.

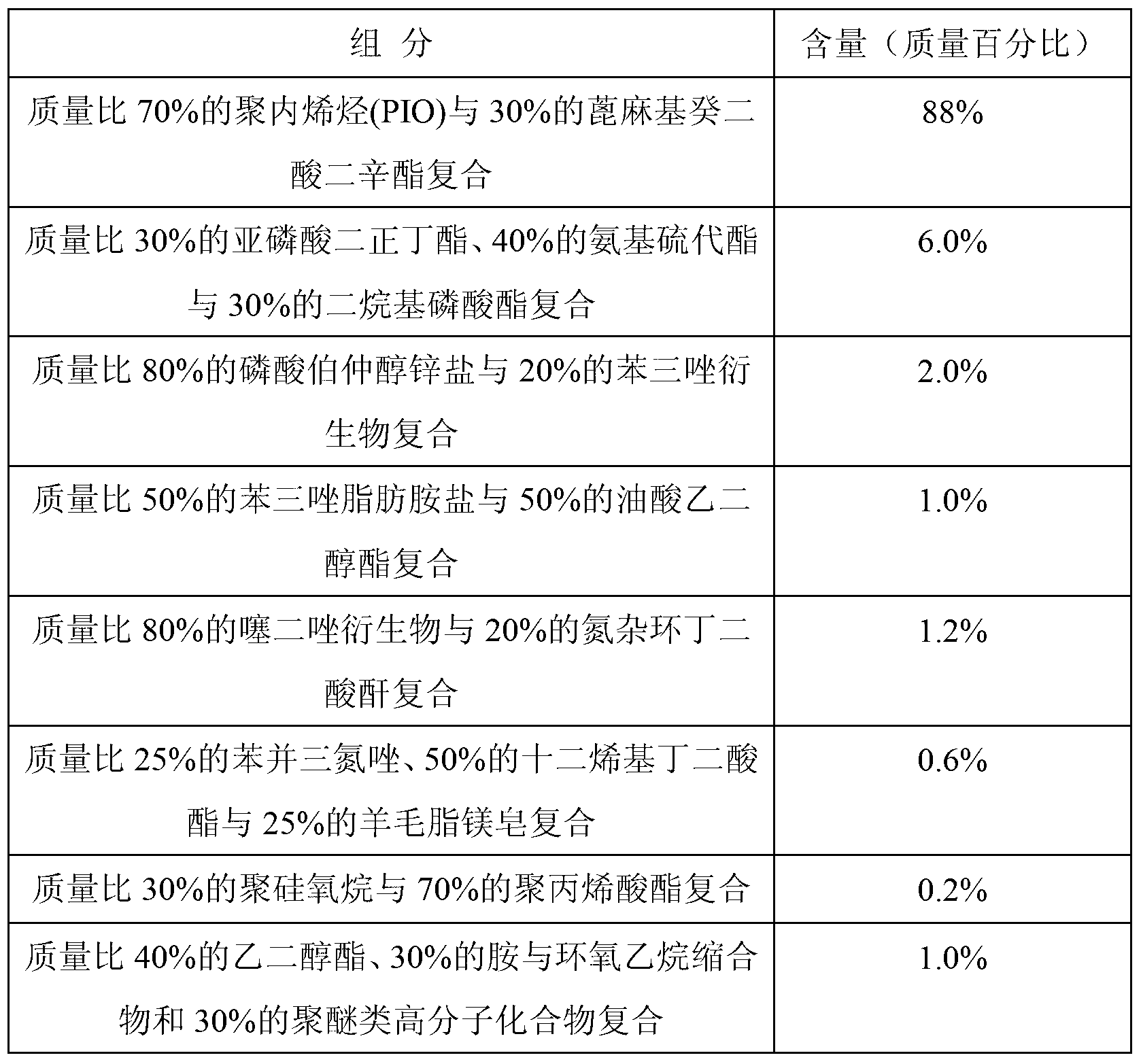

Embodiment 2

[0025] Blend the following components by mass percentage:

[0026]

[0027] The sum of the above components is 100%.

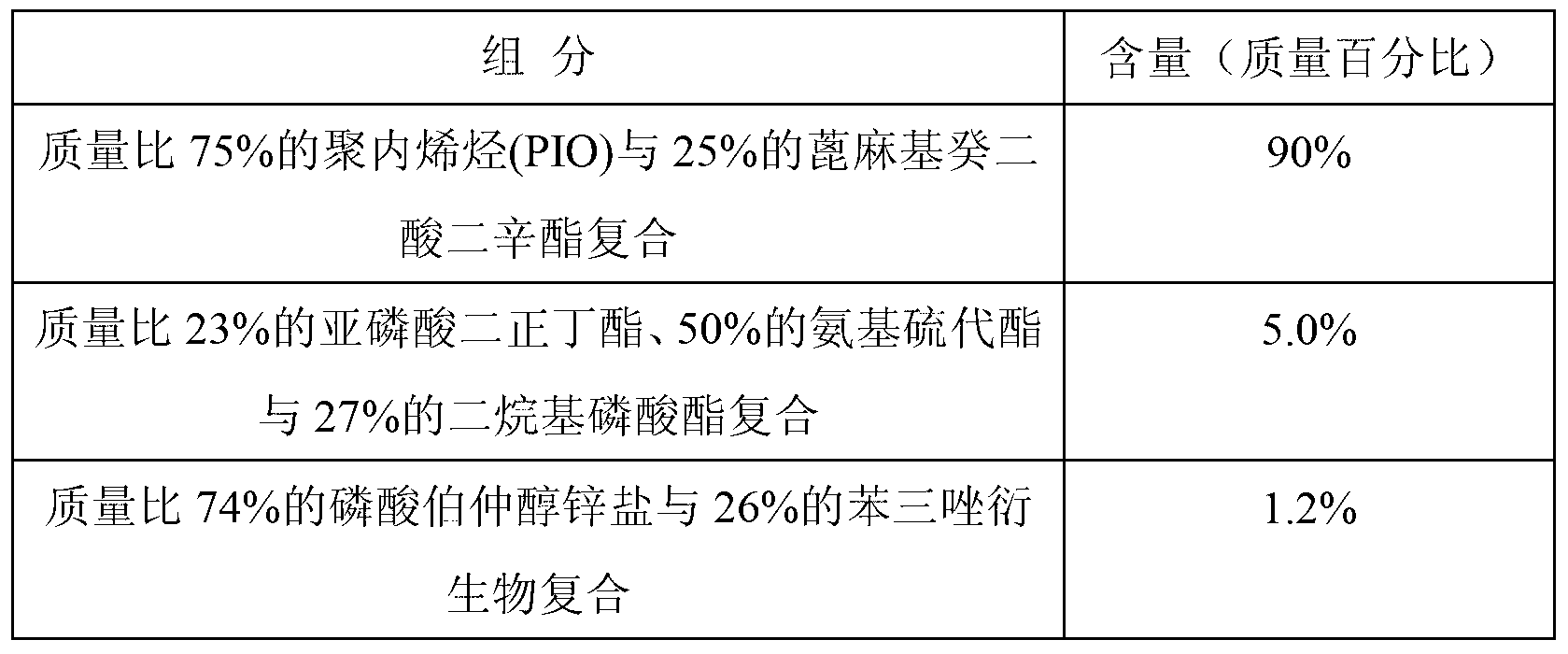

Embodiment 3

[0029] Blend the following components by mass percentage:

[0030]

[0031]

[0032] The sum of the above components is 100%.

[0033] According to the measurement of the provincial technical supervision department, all the physical and chemical indicators of the oil of the present invention meet the use requirements, and polyisobutylene can be blended to meet the performance requirements of GB5903-2011 heavy-duty industrial gear oil viscosity grades: N220 and N320. The typical physical and chemical indicators of Example 2 are shown in Table 1.

[0034] Table 1 Typical physical and chemical indicators of high salt spray resistant industrial gear oil

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com