Centrifugal washing method and washing machine

A technology of centrifugal washing and drum washing machines, which is applied in the field of washing machines, and can solve the problems of taking away clothes stains, sharp increase of washing foam, energy waste, etc., and achieve the effects of saving water resources, washing evenly, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

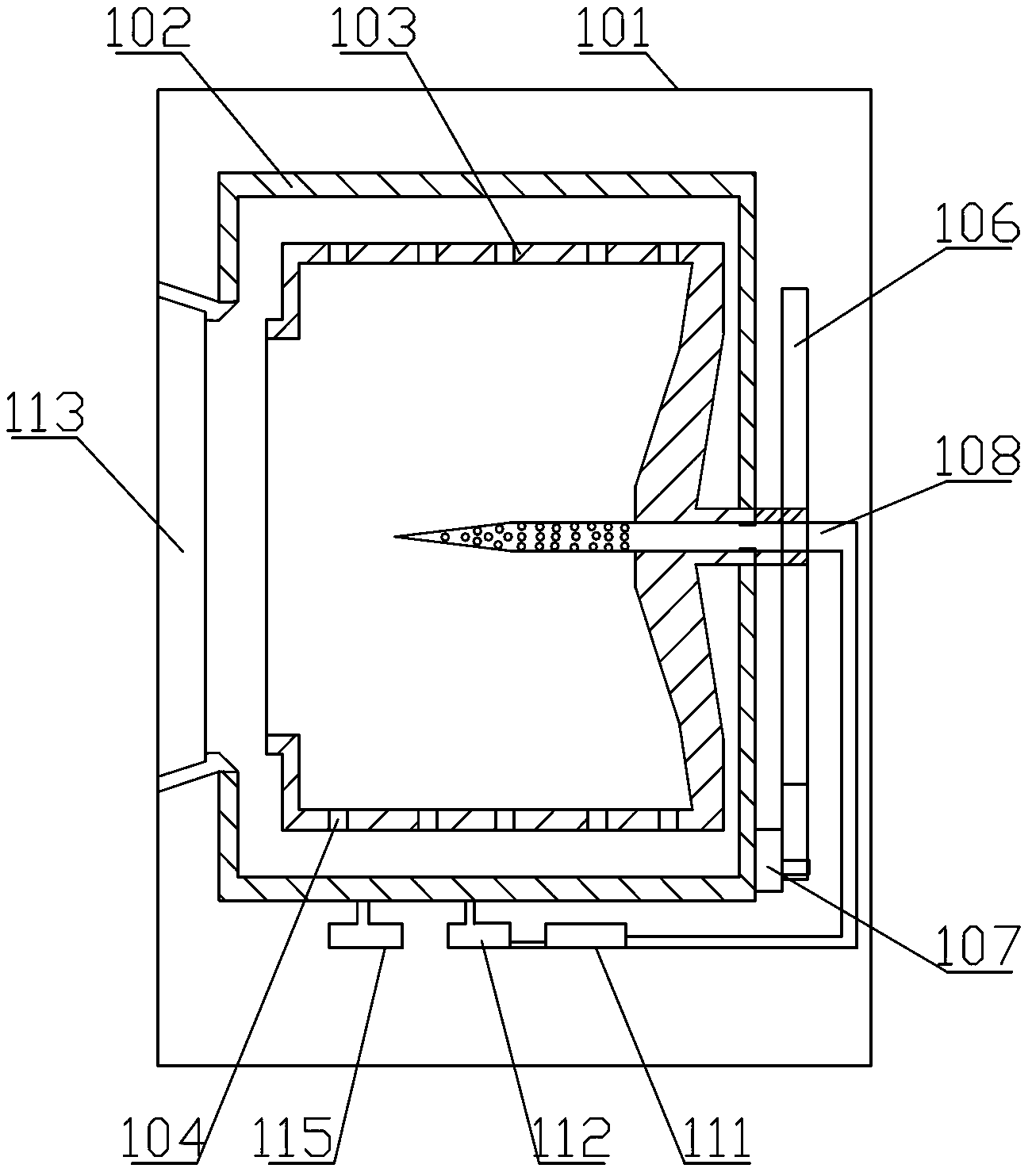

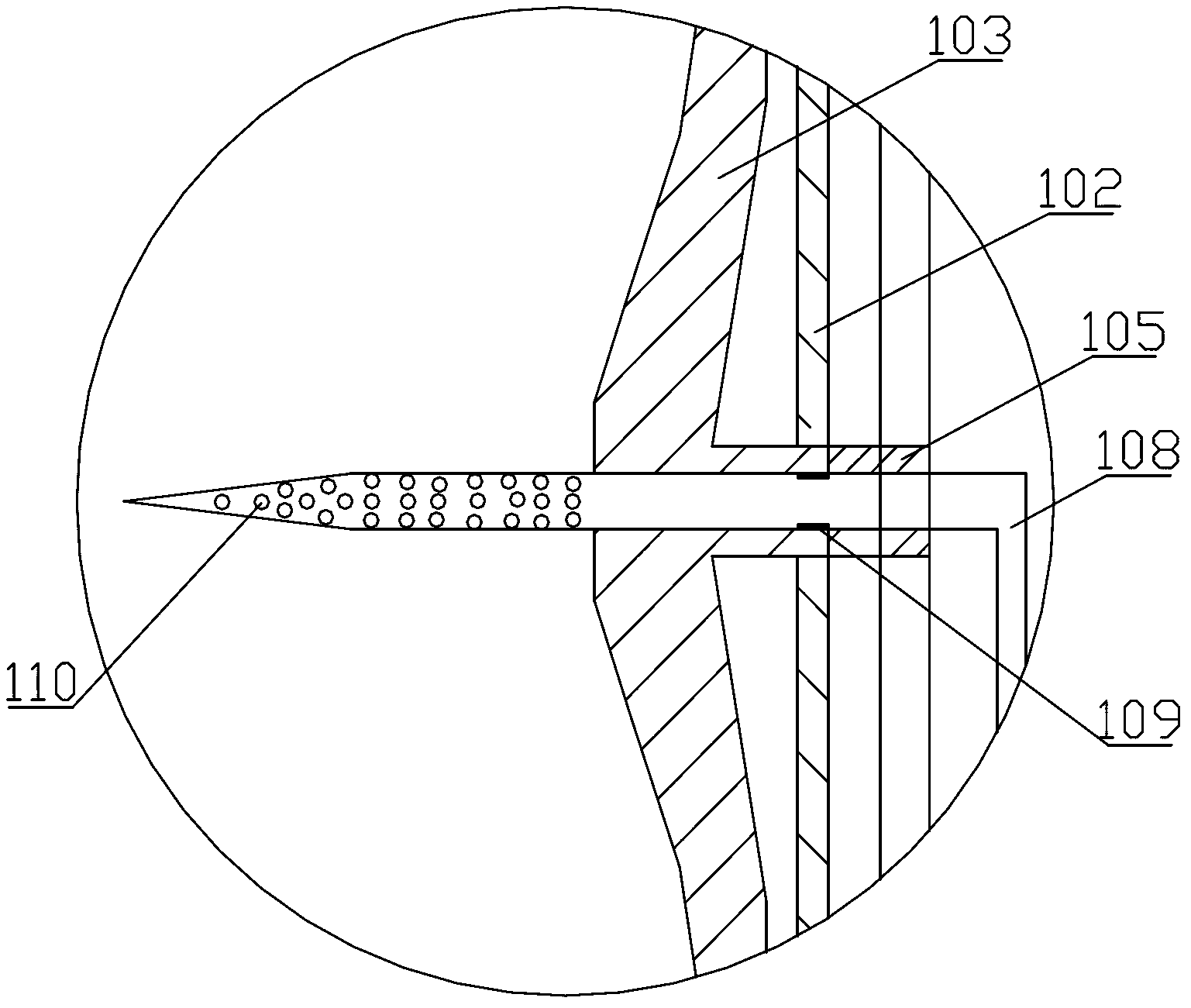

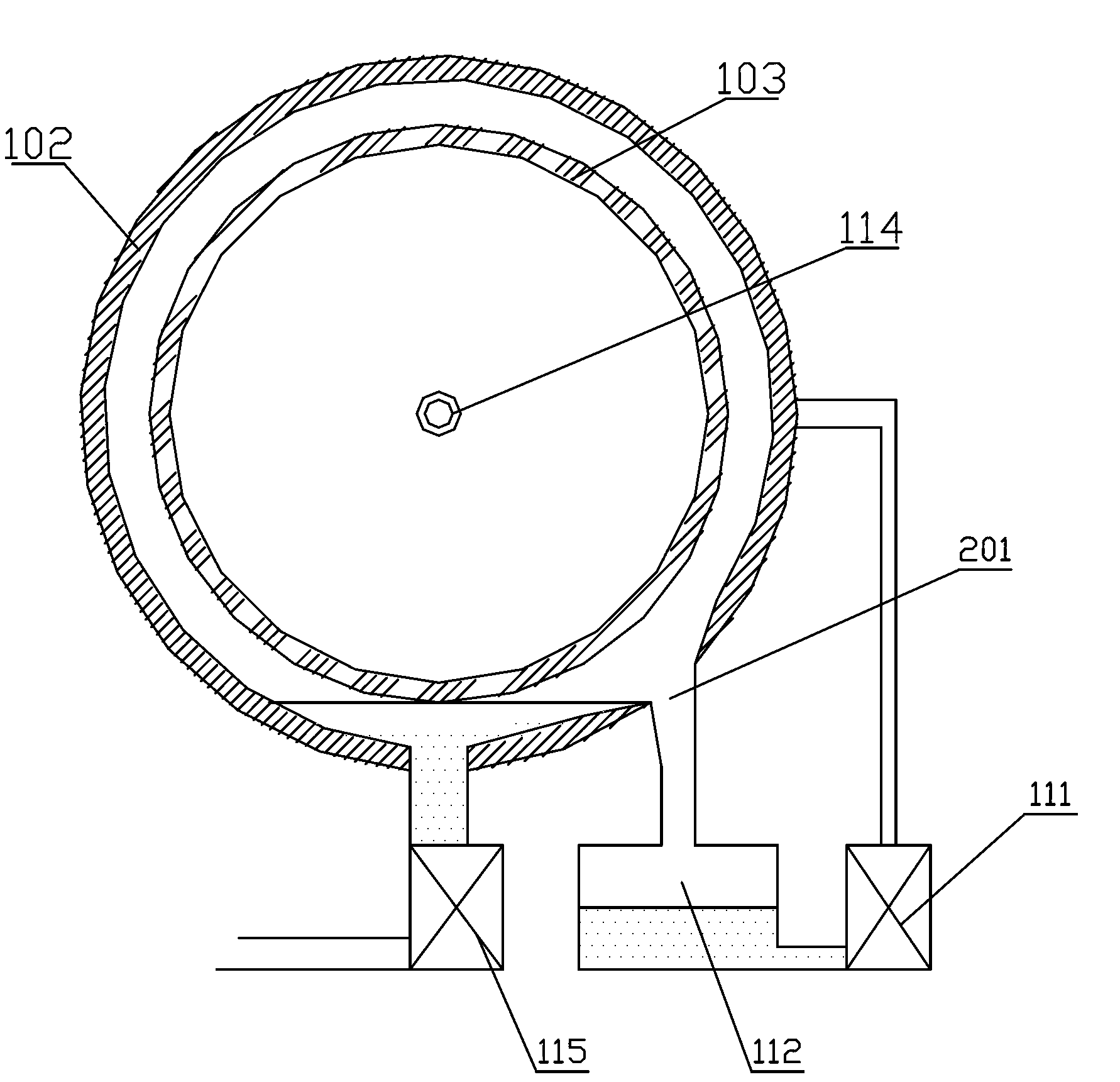

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0035] Such as Figure 1~3 As shown, a kind of centrifugal drum washing machine adopting the centrifugal washing method of the present invention is provided, including a casing 101, a cylindrical outer cylinder 102 for holding water, and a rotatable cylindrical outer cylinder 102 is arranged in the outer cylinder 102. The inner cylinder 103 is provided with regularly arranged small holes 104 on the side wall of the inner cylinder 103 . The inner cylinder 103 and the outer cylinder 102 are arranged horizontally and coaxially, and a rotating shaft 105 is fixedly connected to the inner cylinder 103. The rotating shaft 105 passes through the center of the outer cylinder 102, and its protruding end is connected to the driving motor through a belt 106. 107.

[0036] The rotating shaft 105 is a hollow st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com