Method for butt jointing of prefabricated bridge modulus expansion device by ordinary welding method using bushing sleeve

A telescopic device, assembled technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of high equipment cost and on-site process requirements, adverse effects of waterstops, lack of practicability and reliability, etc. Conducive to simple manual operation and promotion of construction mechanization, maintenance and on-site traffic safety management, and the effect of simple transportation and hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

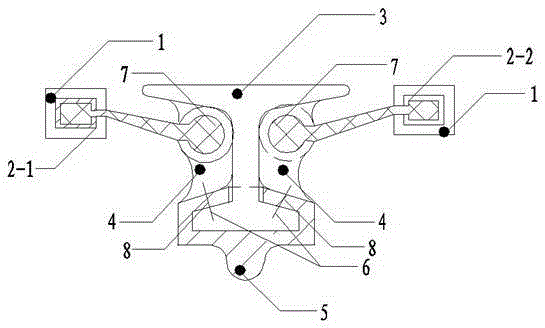

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] Implement the method step of the present invention as shown in the figure as follows:

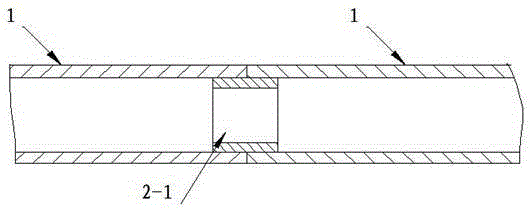

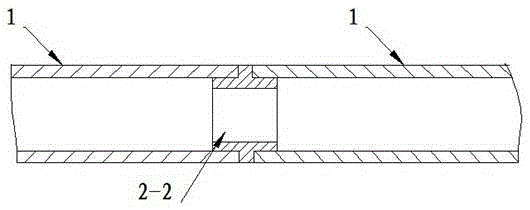

[0028] In the present invention, a bushing 2 matching the cross-section of the waterstop 7 is arranged between the beams of the side beam 1, and its form can be a built-in cylinder (including a pipe cylinder) opening straight-through type 2-1 or a cylinder with a step in the middle 2-2 The opening positioning type (including the pipe cylinder), and the waterproofness after the waterstop 7 is installed; at the same time, the bottom of the butt joint of the middle beam 3 of the modular bridge expansion device is inserted to match the section. The sliding sleeve 5 uses the positioning screw holes 8 on the sliding sleeve 5 and is equipped with an even number of positioning bolts 6 to symmetrically lock and position the end of the beam 3 in the modular bridge teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com