Piston type particle damper

A particle damper and piston technology, which is applied in building components, shockproof and other directions, can solve the problems of difficult to obtain shock absorption effect, the influence of viscous damper energy consumption effect is also large, and the liquid viscous resistance is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

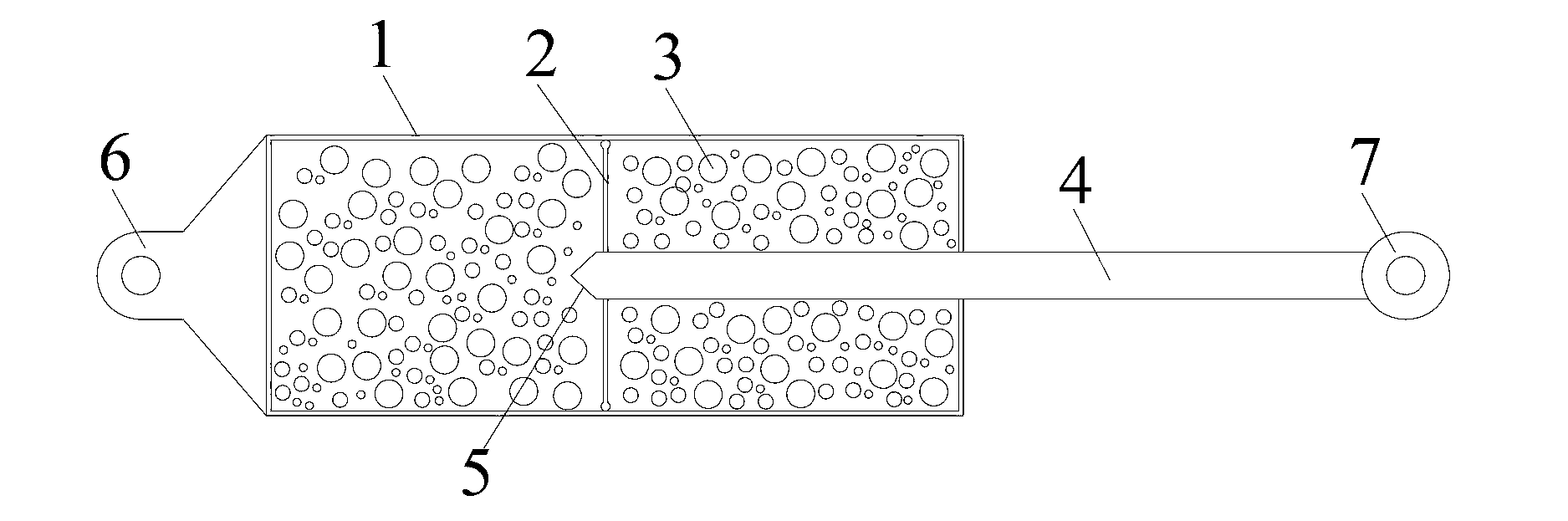

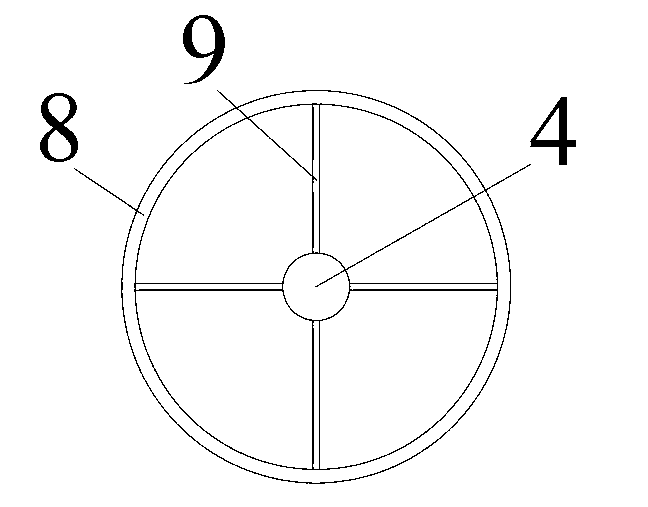

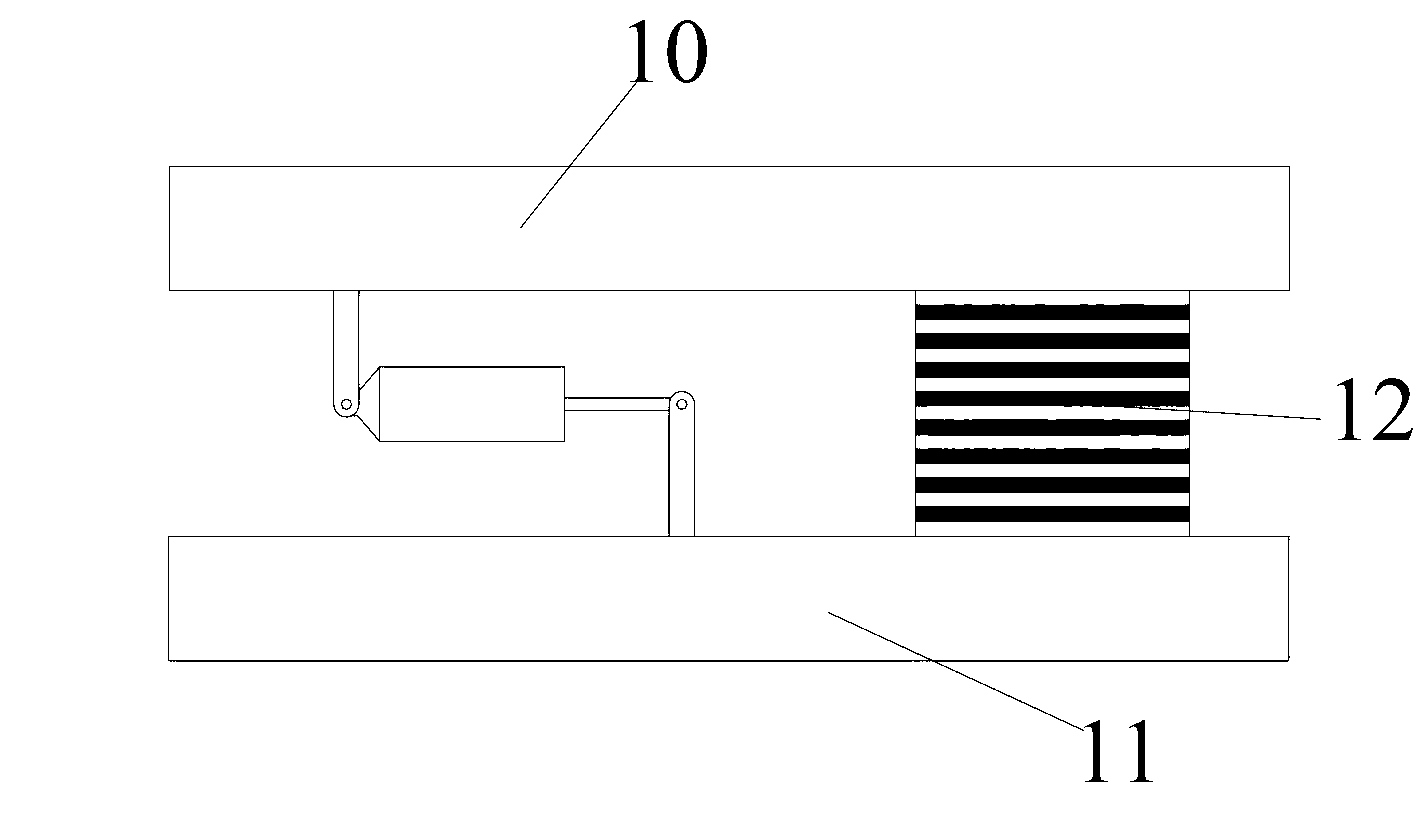

[0024] Such as image 3 As shown, in the rubber bearing isolation structure, the piston-type particle damper and the rubber bearing 12 are installed in parallel between the upper floor 10 of the isolation layer and the foundation 11 to increase the damping of the isolation layer. When the seismic layer moves sideways, the piston rod 4 moves to push the particles 3 through the toggle wheel 2, causing the particles 3 to shift and squeeze each other, thereby dissipating energy.

example 2

[0026] Such as Figure 4 As shown, the piston-type particle damper is used as an energy-dissipating support, and is installed obliquely on the node of the frame structure beam 13 and column 14. When the structure undergoes interlayer displacement, the piston rod 4 moves accordingly and is pushed by the toggle wheel 2. The mutual displacement and extrusion of particles 3 dissipate energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com