Fastening bolt

A technology for fastening bolts and screws, which is applied to threaded fasteners, screws, nuts, etc., can solve the problems of inconvenient installation and disassembly, and achieve the effects of simple disassembly work, improved work efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

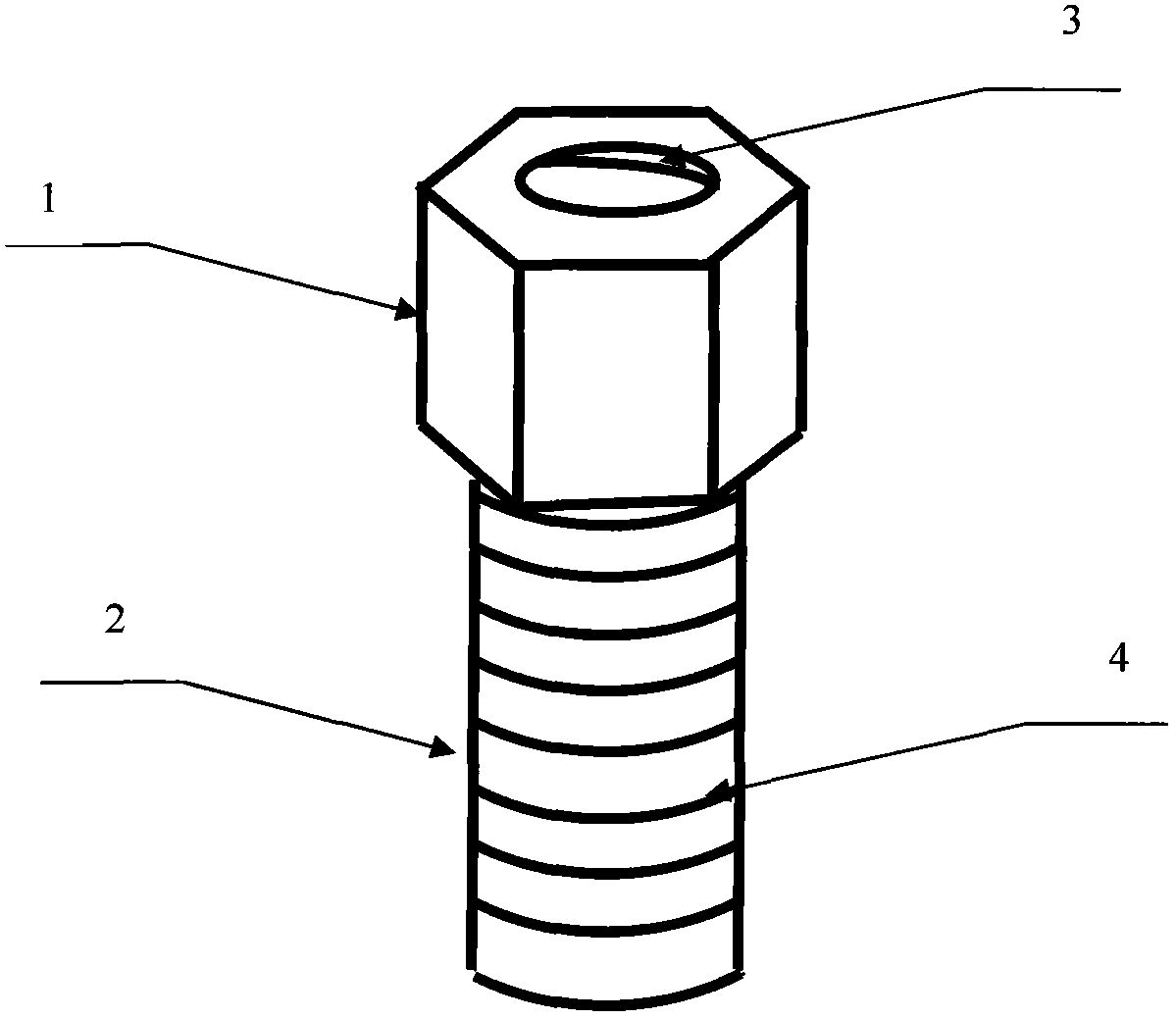

[0009] As shown in the figure, the present invention is mainly composed of an integrated hollow nut 1 and a screw 2, wherein the inner thread 3 of the hollow nut 1 and the outer thread 4 of the screw adopt a reverse thread structure design. According to different occasions and uses, the screw 2 can be made into a hollow screw structure or a solid screw structure, and the outer wall thread of the screw 2 can be made into a whole body thread structure, or can be made into a part thread and part polished rod structure; the hollow nut 1 The geometric shapes and sizes can also be derived and changed according to actual needs, such as: cubes, rectangles, trapezoids, cylinders, elliptical cylinders, pentagons, hexagons and other polygons And other various shapes, as long as the installation tool is matched with it. The geometric dimensions of the hollow nut 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com