Car suspension weld assembly detecting method

A detection method and a technology for vehicle suspension, which are applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of difficult positioning of the support seat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

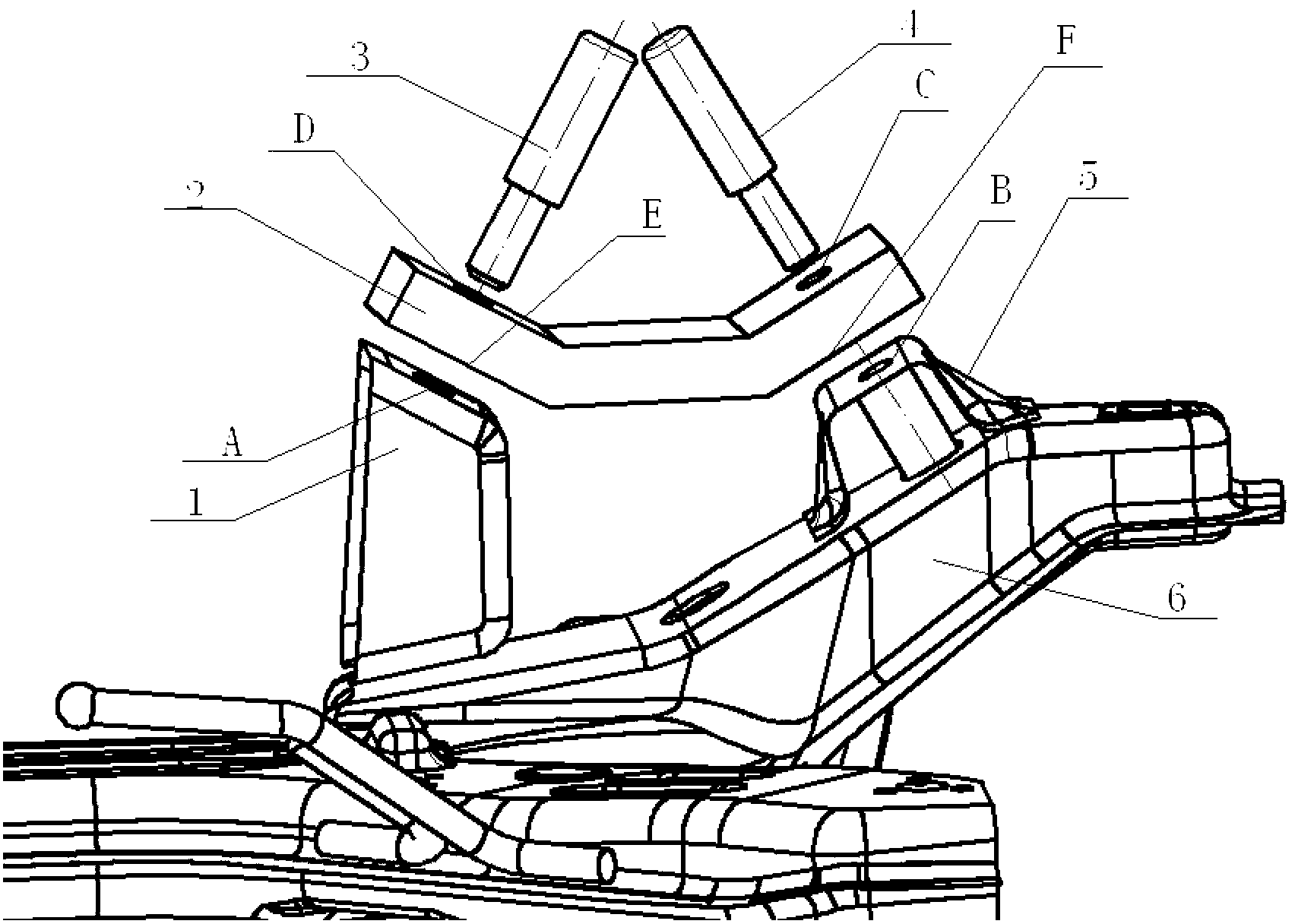

[0011] Referring to the accompanying drawings, a method for detecting an automobile suspension weldment includes the following steps:

[0012] a. Make inspection tools, including a frame body 6, a boat-shaped detection plate 2, and the two ends of the frame body 6 are respectively fixed with a boat-shaped support seat 5, an arch-shaped support seat 1, a boat-shaped support seat 5, and an arch-shaped support seat 1. There are detection holes A and detection holes B respectively. Both ends of the boat-shaped detection plate have reference holes C and reference holes D corresponding to detection holes A and detection holes B. A cylindrical pin 3 is inserted between the detection hole A and the reference hole D. , a waist-shaped hole pin 4 is inserted between the detection hole B and the reference hole C;

[0013] b. Place the boat-shaped detection board on the boat-shaped support base and arch support base to be inspected, insert the cylindrical pin into the detection hole B of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com