Suspension suspensibility measurement apparatus and method for testing suspension suspensibility through gravity center method

A measuring device and technology for suspending liquid, applied in the direction of analyzing materials, instruments, etc., can solve the problems of many operation steps, complicated operation, large test error, etc., and achieve the effect of simple operation and calculation, accurate test data and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

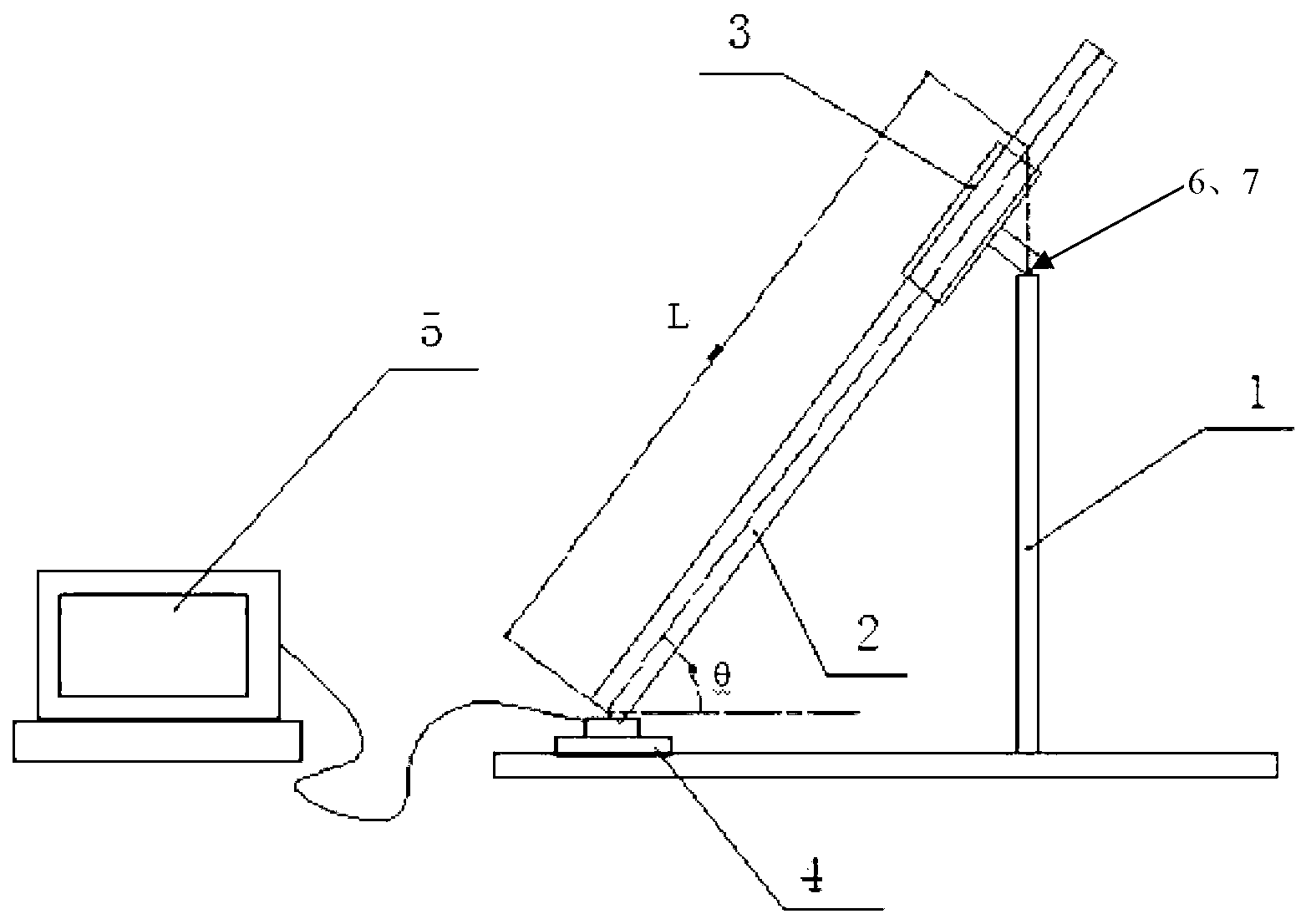

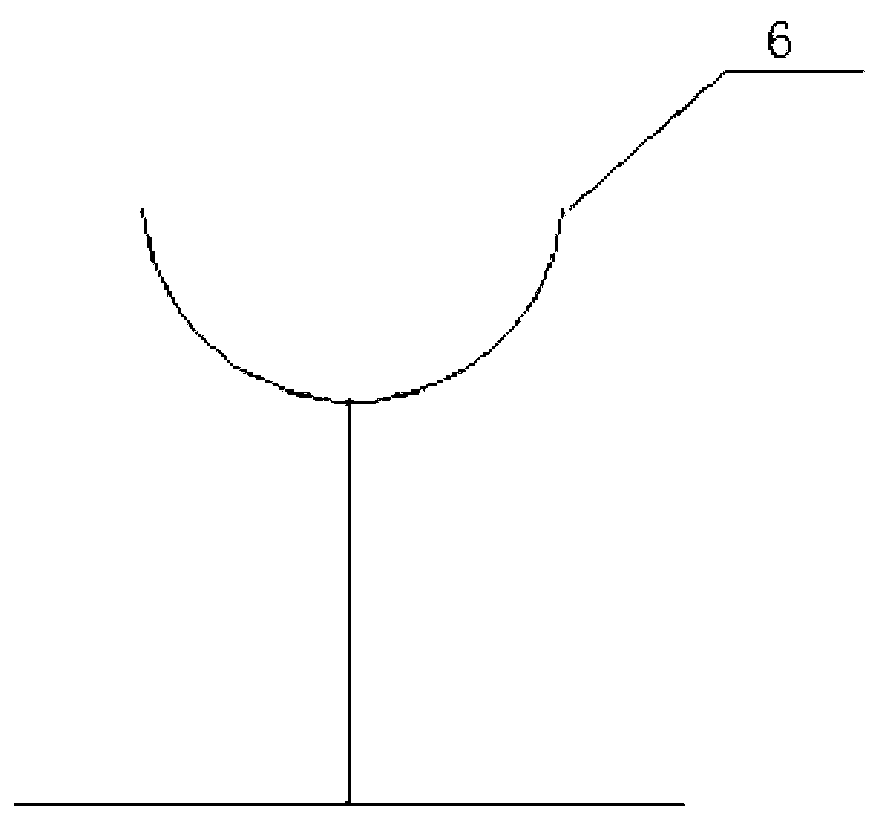

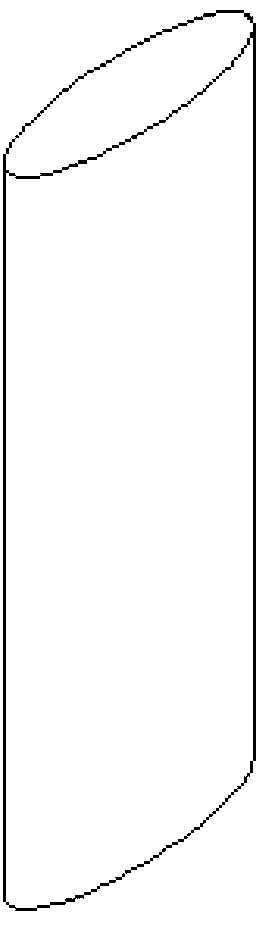

[0042] A suspension measuring device, the structure of which is as follows: figure 1shown. The device includes a bracket (1), a test container (2), a fixture (3), a load cell (4), and a microcomputer (5) with an information collection system. The test container is an oblate long tube container with an oval cross section. The load cell (4) is connected with a microcomputer (5) with an information collection and processing system; the fixture (3) clamps the test container, and the fixture pole (7) is placed on the support end (6) of the bracket (1) Put the lower end of the test container (2) on the test end (8) of the load cell (4), the angle between the test container and the horizontal plane is θ, θ=10~85°

Embodiment 2

[0044] A suspension performance test of a high-radiation infrared energy-saving coating, the test device is as in Example 1. The force sensor is connected with a microcomputer with an acquisition system, the fixture is fixed on the upper end of the container, the straight line where the fixture pole is located is perpendicular to the centerline of the container in the longitudinal direction, and the intersection point between the plane perpendicular to the horizontal plane where the fixture pole is located and the centerline in the longitudinal direction of the vessel is The distance between the bottom of the test container is L=400mm, the fixture pole is placed on the supporting end of the bracket, the lower end of the test container is placed on the test end of the load cell, and the angle between the test container and the horizontal plane is θ=60°. Record the number of load cells at this time F 0 =0.5N; after loading a certain amount of suspension with a mass of M=180g, th...

Embodiment 3

[0055] A kind of suspension measuring device, replaces the load cell in embodiment 2 with electronic analytical balance, other is the same as embodiment 2. In embodiment 2, the force F measured by the load cell is multiplied by the acceleration of gravity g by the value m measured by the electronic balance in this device, that is, F=mg, F 0 =m 0 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com