Photosensitive resin composition for color filter and color filter using same

A color filter and photosensitive resin technology, applied in the field of color filters, can solve problems such as poor durability, and achieve the effects of excellent durability, excellent brightness characteristics, and excellent light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] (A) Dye

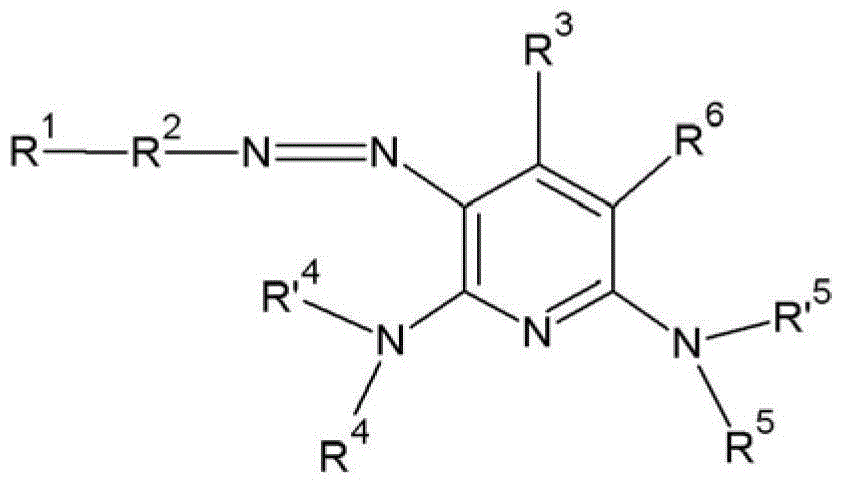

[0103] 3.4 grams of dye represented by the following chemical formula 2 (A-1, CF Yellow 100108, KWng-InSynthetic Corporation)

[0104] [chemical formula 2]

[0105]

[0106] (A'-1) red pigment dispersion

[0107] 18.36 grams of CHR50-R254 (14.75% pigment solids, Mikuni Corp.)

[0108] 2.24 grams of CHR50-R254 (12.88% pigment solids, Mikuni Corp.)

[0109] (B) Acrylic binder resin

[0110]5.0 grams of methacrylic acid / benzyl methacrylate (30 / 70 (w / w), molecular weight (Mw)=28,000)

[0111] (C) Acrylic photopolymerizable monomer

[0112] 12.3 grams of dipentaerythritol hexaacrylate

[0113] (D) Photopolymerization initiator

[0114] 2.0 g of oxime photopolymerization initiator (CGI-124, Ciba Specialty Chemicals Corp.)

[0115] (E) solvent

[0116] 33.8 grams of propylene glycol monomethyl ether acetate

[0117] 12.7 g of ethyl 3-ethoxypropionate

[0118] (F) Surfactant

[0119] 0.2 g of fluorosurfactant (F-482, DIC Inc.)

[0120] 2.0 g of the pho...

Embodiment 2

[0122] (A) Dye

[0123] 2.38 grams of the dye (A-1) represented by the above chemical formula 2 (CF Yellow100108, KWng-InSyntheticCorporation)

[0124] (A'-1) red pigment dispersion

[0125] 30.6 grams C.I. Pigment Red 254 / C.I. Pigment Red 177 (60 / 40 mix by weight ratio, 4.9 grams solids)

[0126] (A'-2) yellow pigment

[0127] 1.02 g C.I. Pigment Yellow 150

[0128] (B) Acrylic binder resin

[0129] 5.0 g of copolymer of acrylic acid / benzyl methacrylate (Miwon Commercial Co., Ltd, NPR1520)

[0130] (C) Acrylic photopolymerizable monomer

[0131] 12.3 g dipentaerythritol hexaacrylate

[0132] (D) Photopolymerization initiator

[0133] 2.0 grams of oxime photopolymerization initiator (CGI-124)

[0134] (E) solvent

[0135] 33.8 g propylene glycol monomethyl ether acetate

[0136] 12.7 g ethyl 3-ethoxypropionate

[0137] (F) Surfactant

[0138] 0.2 g of fluorosurfactant (F-482, DIC Inc.)

[0139] 2.0 g of the photopolymerization initiator (D) was dissolved in 33.8 g...

Embodiment 3

[0141] A photosensitive resin composition was prepared according to the same method as in Example 2, but 2.38 g of dye (A-1) was used instead of 2.04 g of dye (A-1) and 1.36 g of yellow pigment (A'-2) was used instead of 1.02 g of yellow pigment (A'-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

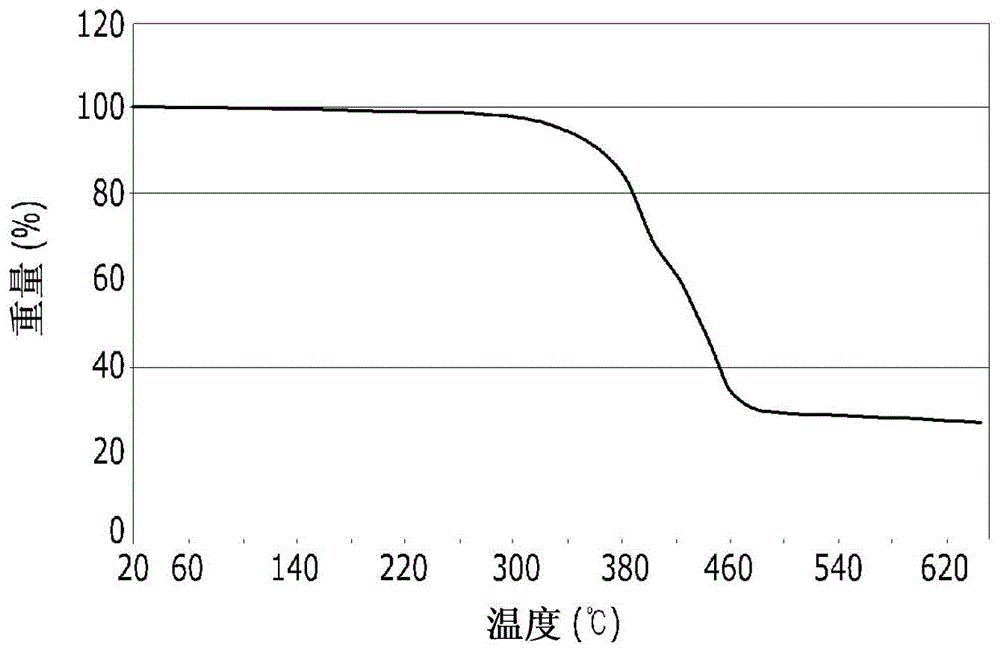

| thermal decomposition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

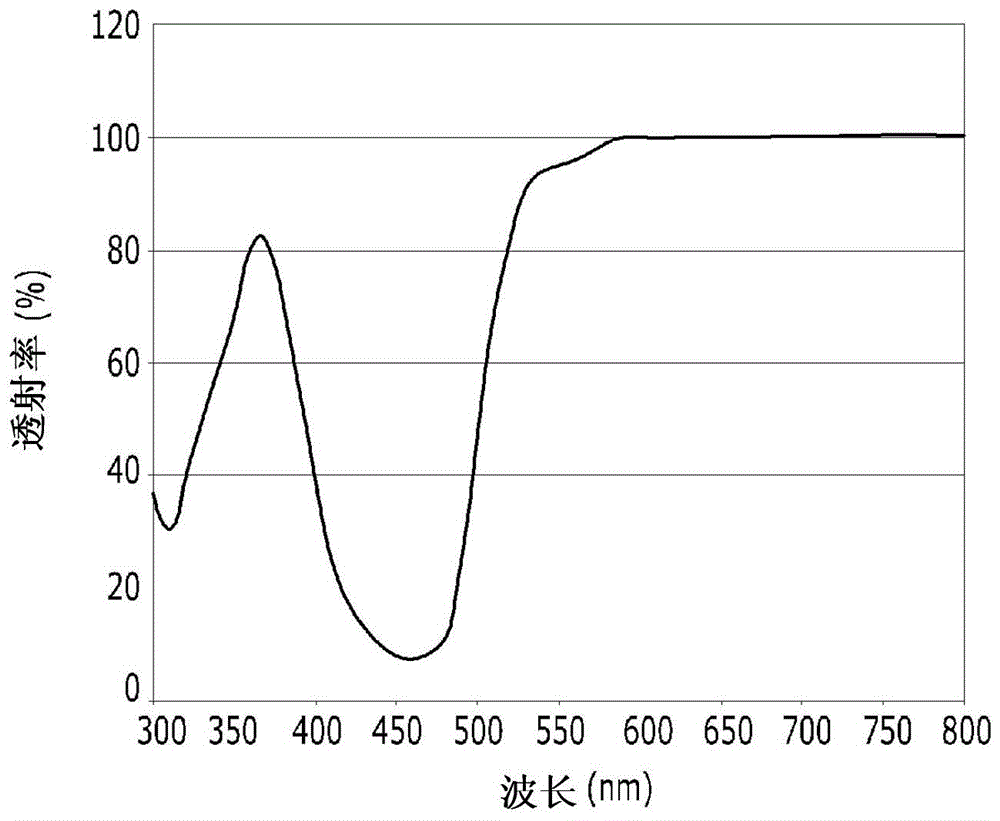

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com