charge transport varnish

A charge transport, varnish technology, applied in circuits, electric light sources, electrical components, etc., to achieve the effect of high yield and high charge transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0143] Hereinafter, synthesis examples, examples, and comparative examples are given to describe the present invention more specifically, but the present invention is not limited to the following examples. In addition, the apparatuses used are as follows.

[0144] (1) 1 H-NMR measurement: High-resolution nuclear magnetic resonance apparatus manufactured by Barian

[0145] (2) Substrate cleaning: Substrate cleaning equipment manufactured by Changzhou Sangyo Co., Ltd. (decompression plasma method)

[0146] (3) Coating of varnish: spin coater MS-A100 manufactured by Mikasa Co., Ltd.

[0147] (4) Film thickness measurement: Micro shape measuring machine Surfcorder ET-4000 manufactured by Kosaka Laboratories Co., Ltd.

[0148] (5) Manufacture of EL elements: Multifunctional vapor deposition system C-E2L1G1-N manufactured by Changzhou Sangyo Co., Ltd.

[0149] (6) Measurement of luminance, etc. of EL elements: (Yes) I-V-L measurement system manufactured by Tek World

[0150] (7...

Synthetic example 1

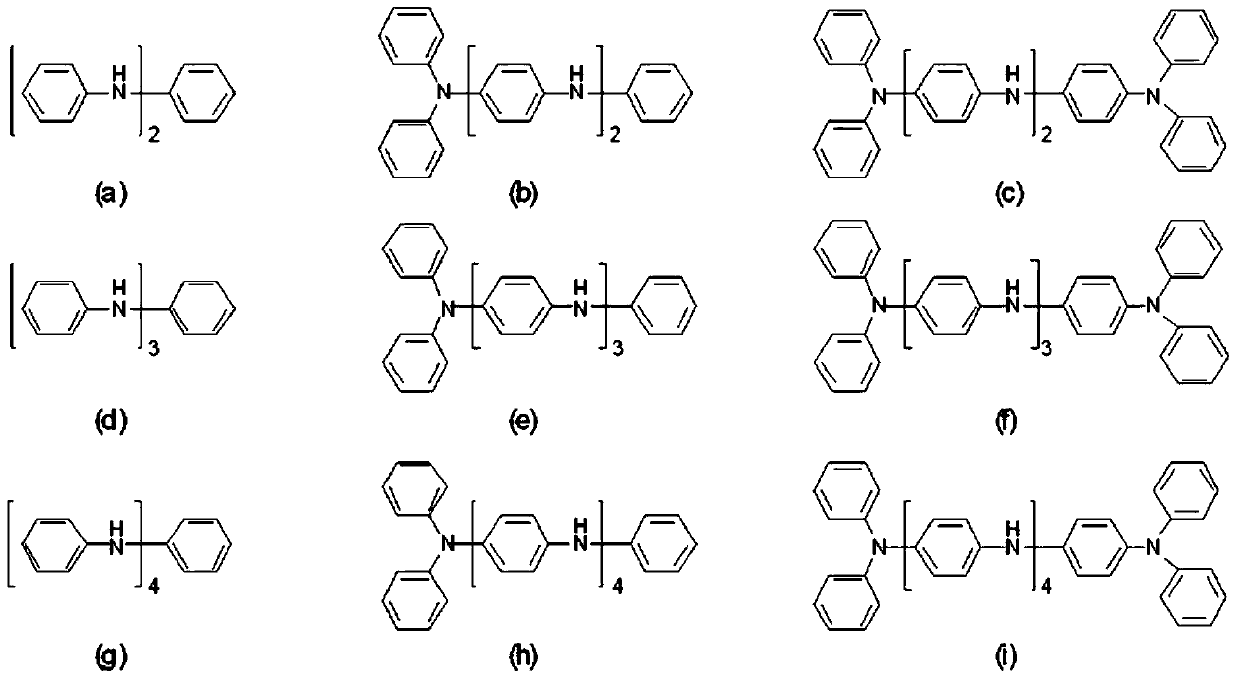

[0152] [Synthesis Example 1] Synthesis of Aniline Derivatives

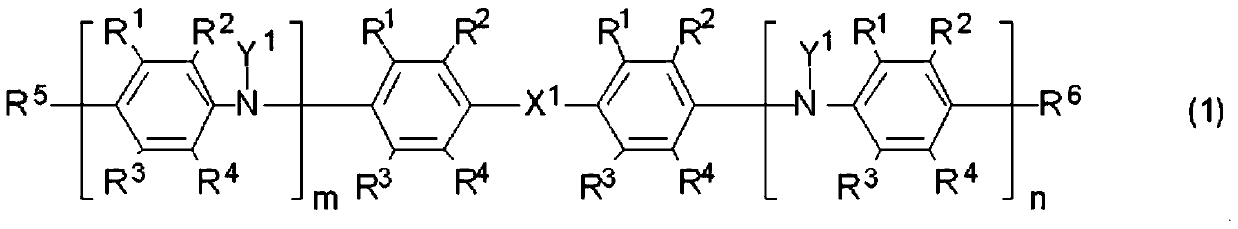

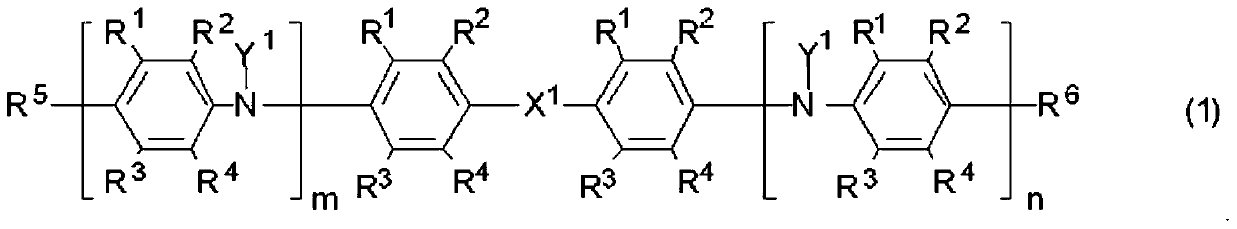

[0153] [chemical 6]

[0154]

[0155] In the mixed suspension of 4,4'-diaminodiphenylamine 10.00g (50.19mmol), 4-bromotriphenylamine 34.17g (105.40mmol) and xylene (100g), add tetrakis (triphenyl 0.5799 g (0.5018 mmol) of phosphine)palladium and 10.13 g (105.40 mmol) of sodium tert-butoxide were stirred at 130° C. for 14 hours under nitrogen.

[0156] Then, the reaction mixture was filtered, saturated brine was added to the filtrate, and after liquid separation treatment, the solvent was distilled off from the organic layer, and the obtained solid was recrystallized using 1,4-dioxane to obtain Target aniline derivative (yield: 22.37 g, yield: 65%).

[0157] 1 H-NMR (CDCl 3 ): δ7.83(S, 2H), 7.68(S, 1H), 7.26-7.20(m, 8H), 7.01-6.89(m, 28H).

[0158] [2] Preparation of charge transport varnish

Embodiment 1-1

[0160] 0.206 g of the aniline derivative obtained in Synthesis Example 1 and 0.412 g of phosphotungstic acid (manufactured by Kanto Chemical Co., Ltd.) were dissolved in 4.0 g of diethylene glycol monomethyl ether under a nitrogen atmosphere. 16.0 g of propylene glycol monomethyl ether was added to the obtained solution, stirred, and 0.021 g of 3,3,3-trifluoropropyltrimethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd.) and phenyltrimethoxysilane were added thereto. Silane (manufactured by Shin-Etsu Chemical Co., Ltd.) 0.041 g was further stirred to prepare a charge-transporting varnish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com