Casting technique of V12-type engine cylinder block

A technology of engine cylinder block and casting technology, which is applied to casting molding equipment, casting molds, cores, etc. It can solve problems such as complex structure of castings, seepage of molten iron, casting molding, and poor shape and size, so as to improve the accuracy of shape and size and internal and external surface quality, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

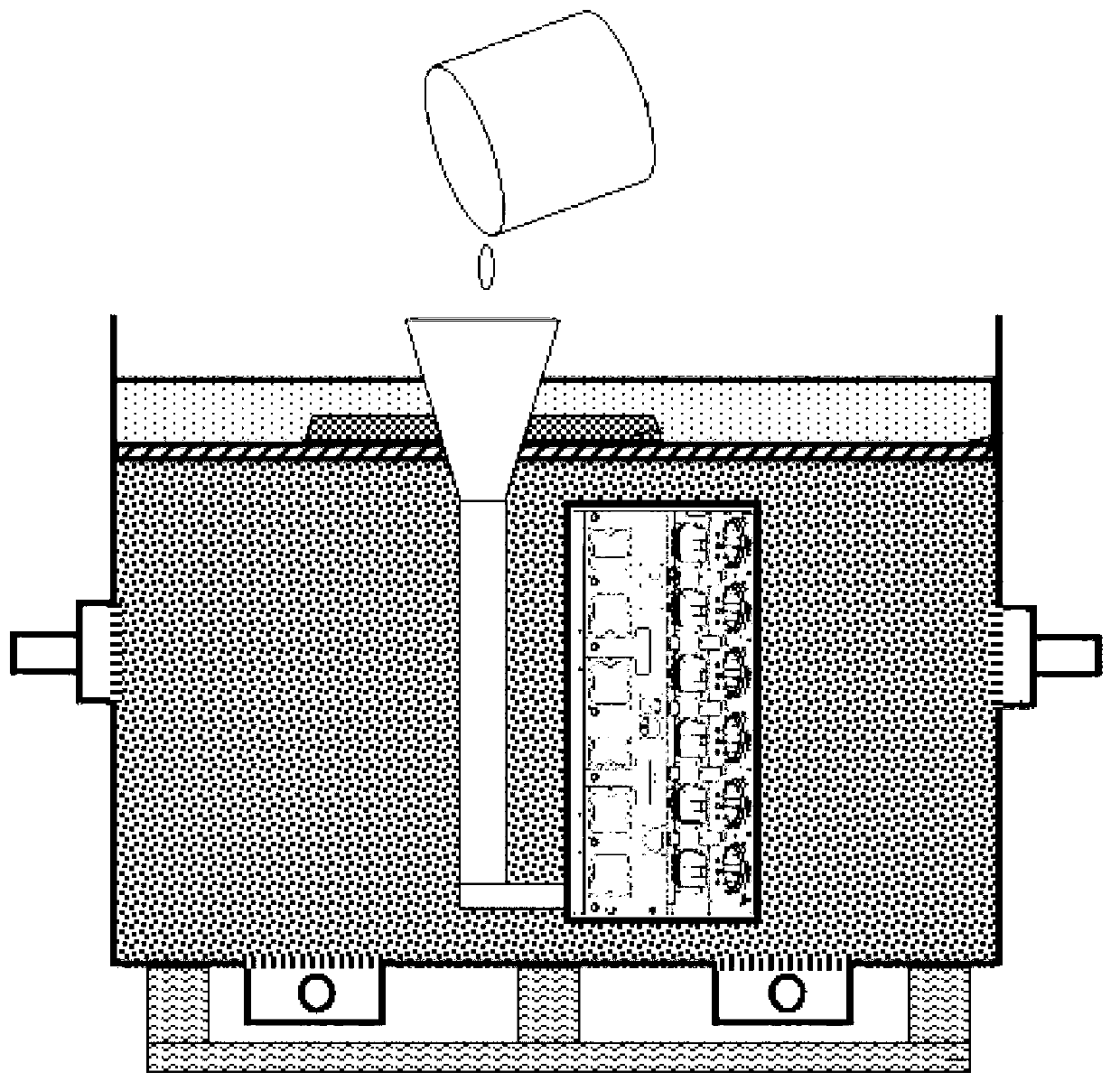

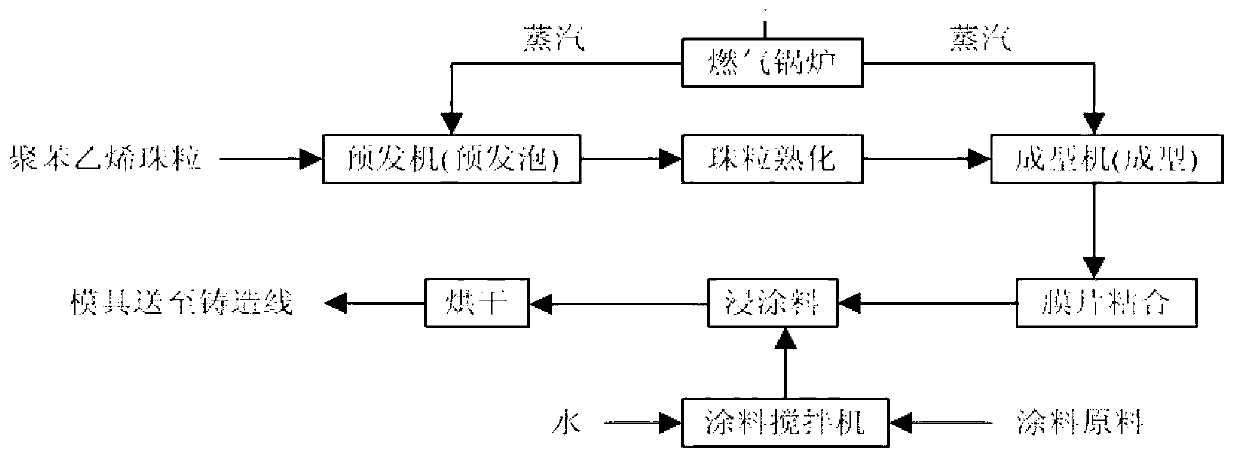

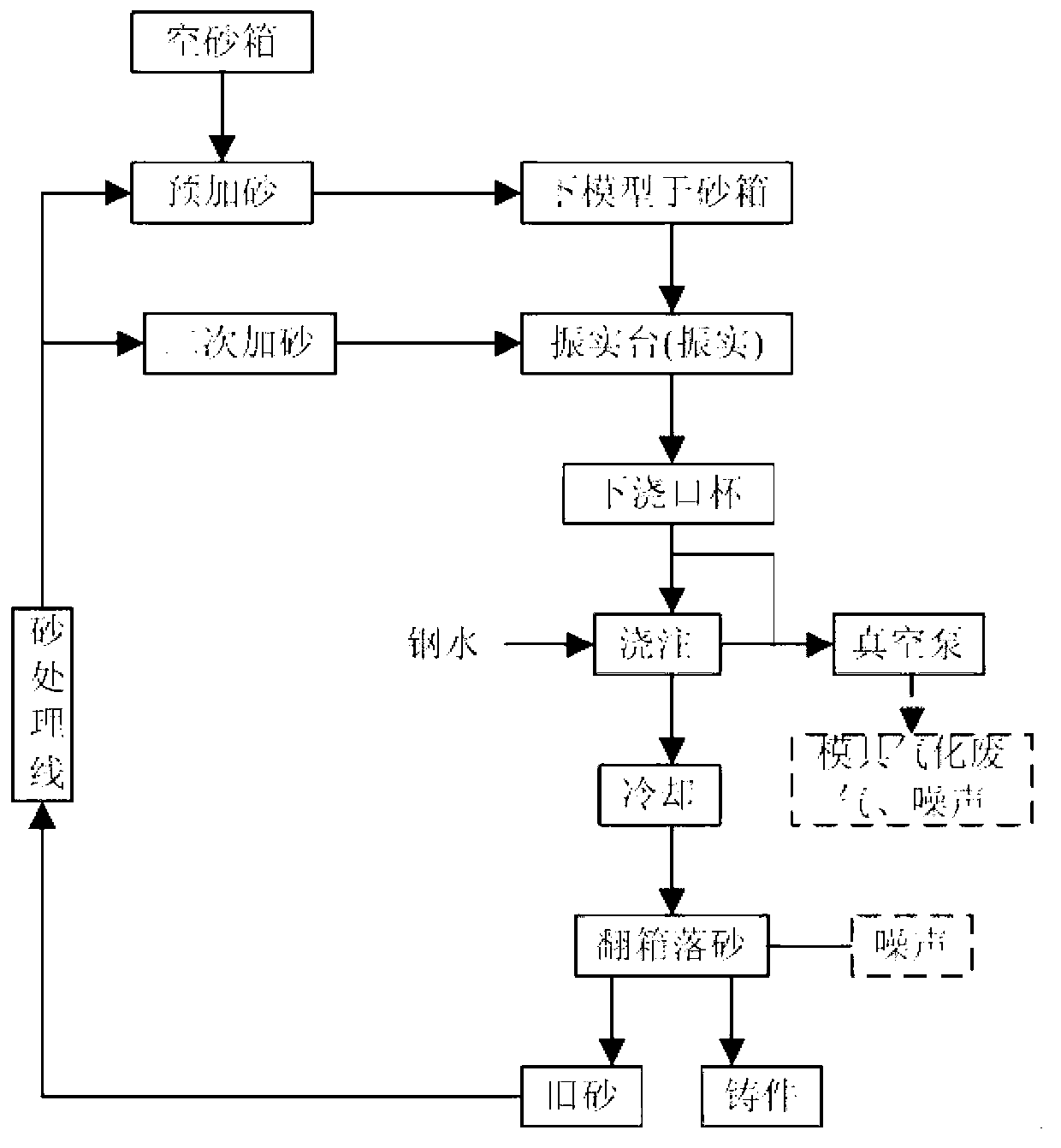

[0022] Example: see figure 1 , figure 2 , image 3 and Figure 4 , a casting technology for a V12 engine block, the specific steps include: making a foam plastic model, vibration molding, vacuum pouring and cooling cleaning, pumping air to the sand mold during pouring, and before and after the pouring stage, and the pumping pipeline is installed on At the lower end of the sand mold, an iron pillow to disperse the force is placed on the sprue cup, and a layer of water glass sand is covered on the film. Before pouring, start the vibrating table to make the sand box vibrate continuously during the pouring process. The V12 engine cylinder block with complex structure is produced and manufactured by the improved lost foam casting process and the dense strengthening casting method while vibrating, and the V12 engine cylinder is further improved by using the nearly no margin and precise molding process of lost foam. The shape and size accuracy of the body and the quality of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com